Method for measuring profile tolerance of large-size mortise on small-diameter projector

A technology of projector and profile, which is applied in the field of mechanical processing, can solve the problems of affecting the detection efficiency and high cost of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail;

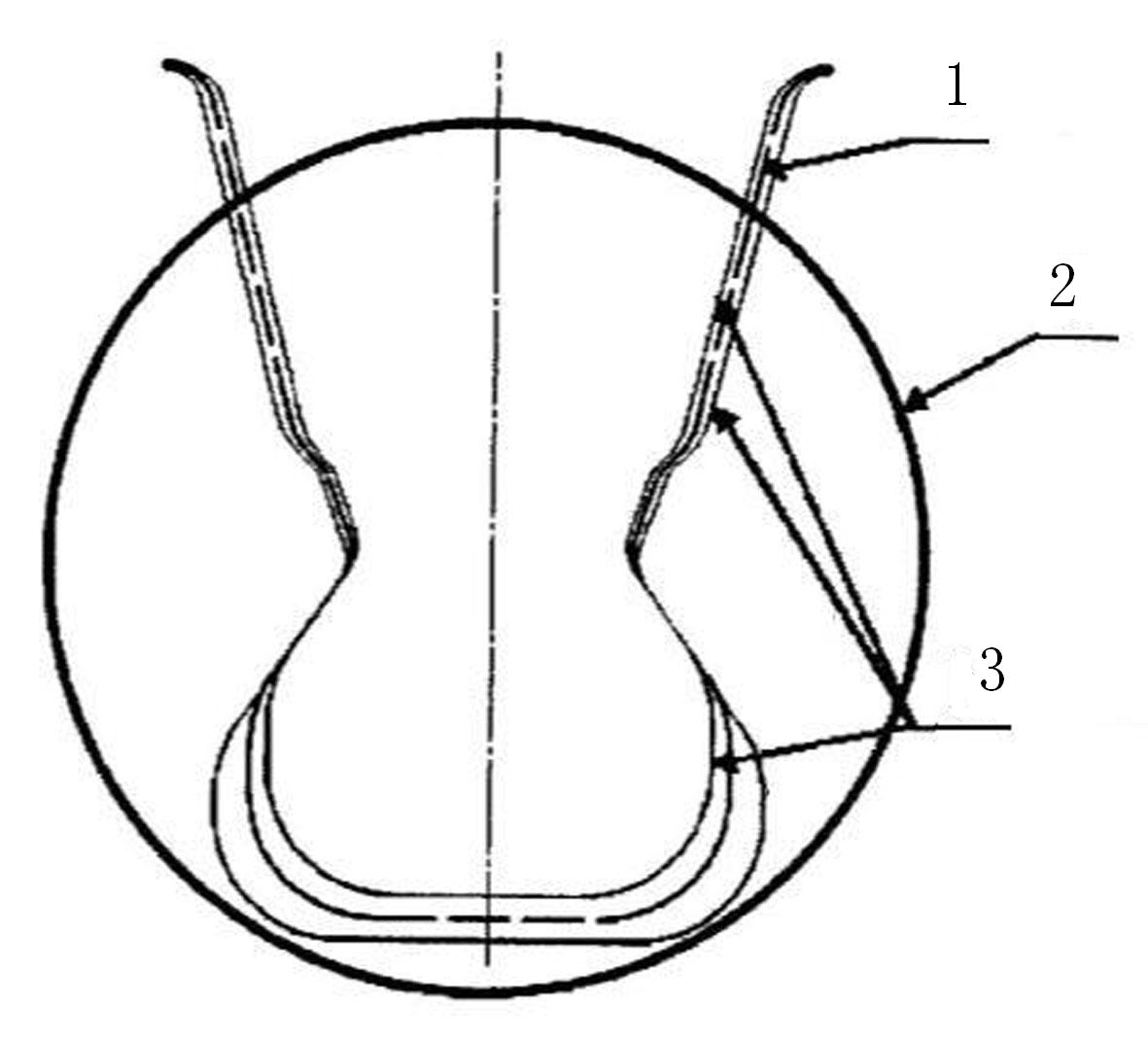

[0024] The projector in the embodiment adopts the Cyclop type projector of Italian LTF company, and the projector screen is a circular screen with a diameter of Φ1000mm; the maximum external dimension of the tenon groove: 24mm×14mm, after the projection of the tenon and groove is enlarged by 50 times, the projection image of the tenon and groove The size is 1200mm×700mm, which exceeds the screen size of the projector, so it is necessary to adopt the method of the present invention for measuring the profile of a large-sized tongue and groove on a small-diameter projector, and measure according to the method of partitioning, and specifically follow the following steps:

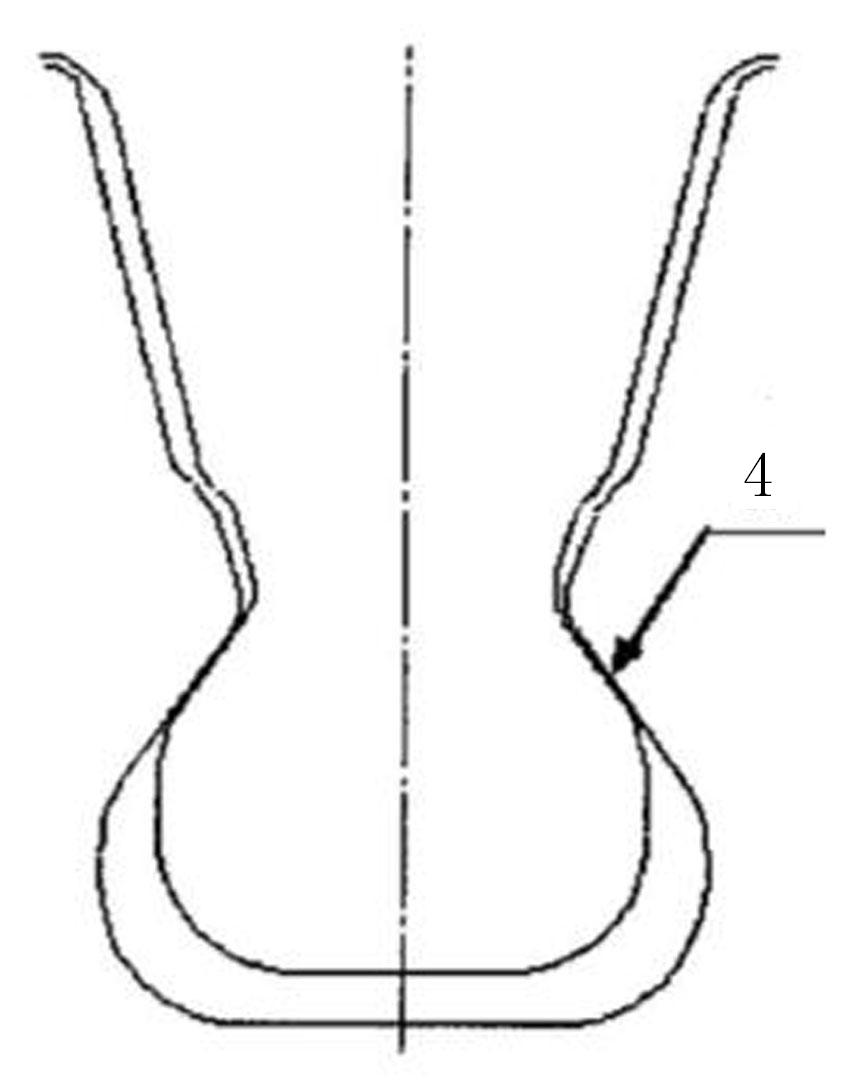

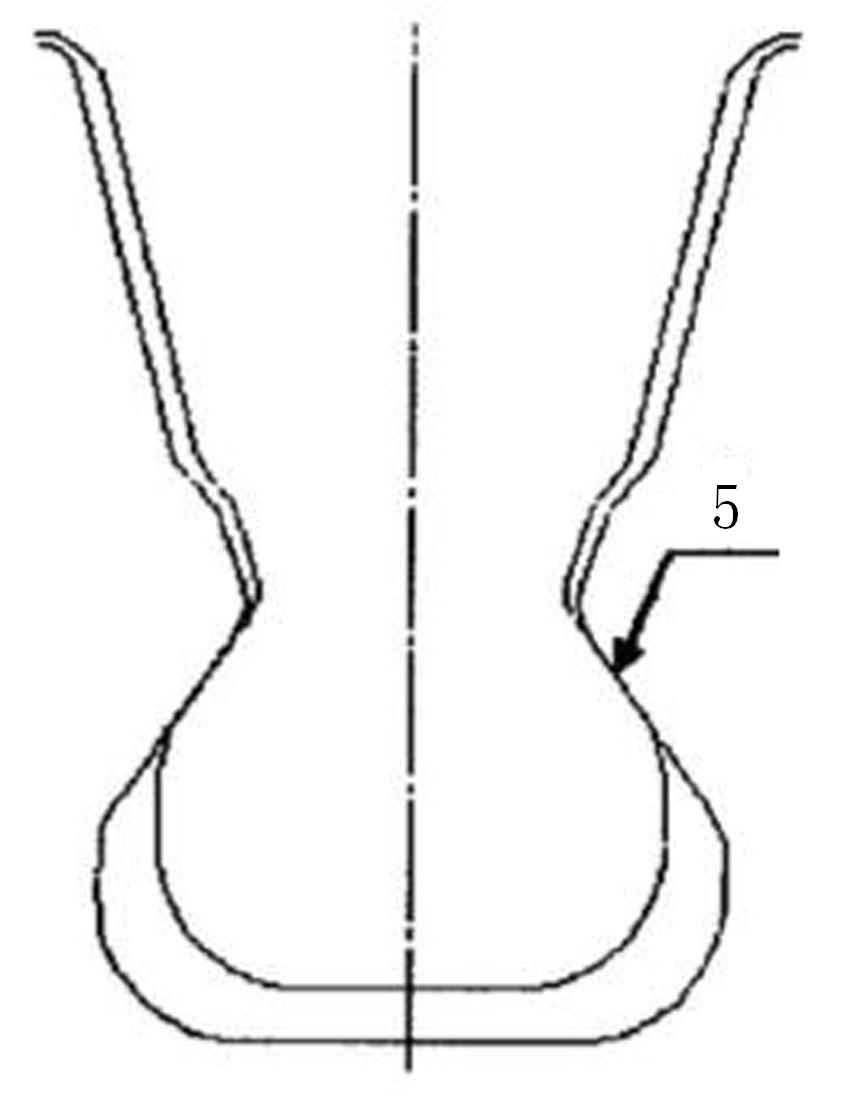

[0025] Step 1. Set the tolerance zone of the tongue and groove profile image 3 Double contour line 4 in the tongue and groove face part, see figure 2 , the compression tolerance becomes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com