Pivot pin retainer mechanism

A retainer and pivot technology, which is applied to the special position of the vehicle, vehicle components, movable seats, etc., can solve the problems of increasing complexity and cost, difficulty in manual installation, and large installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

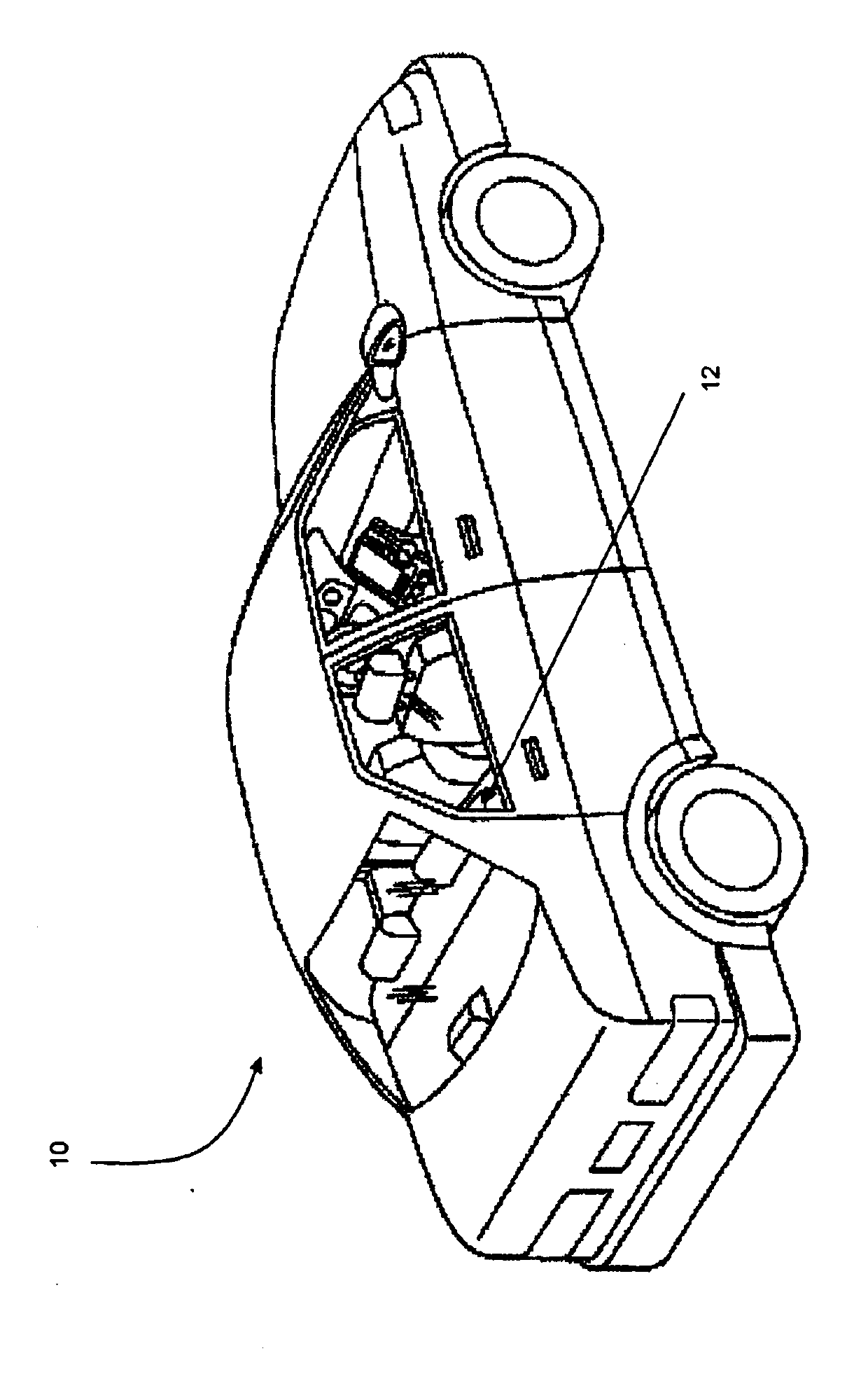

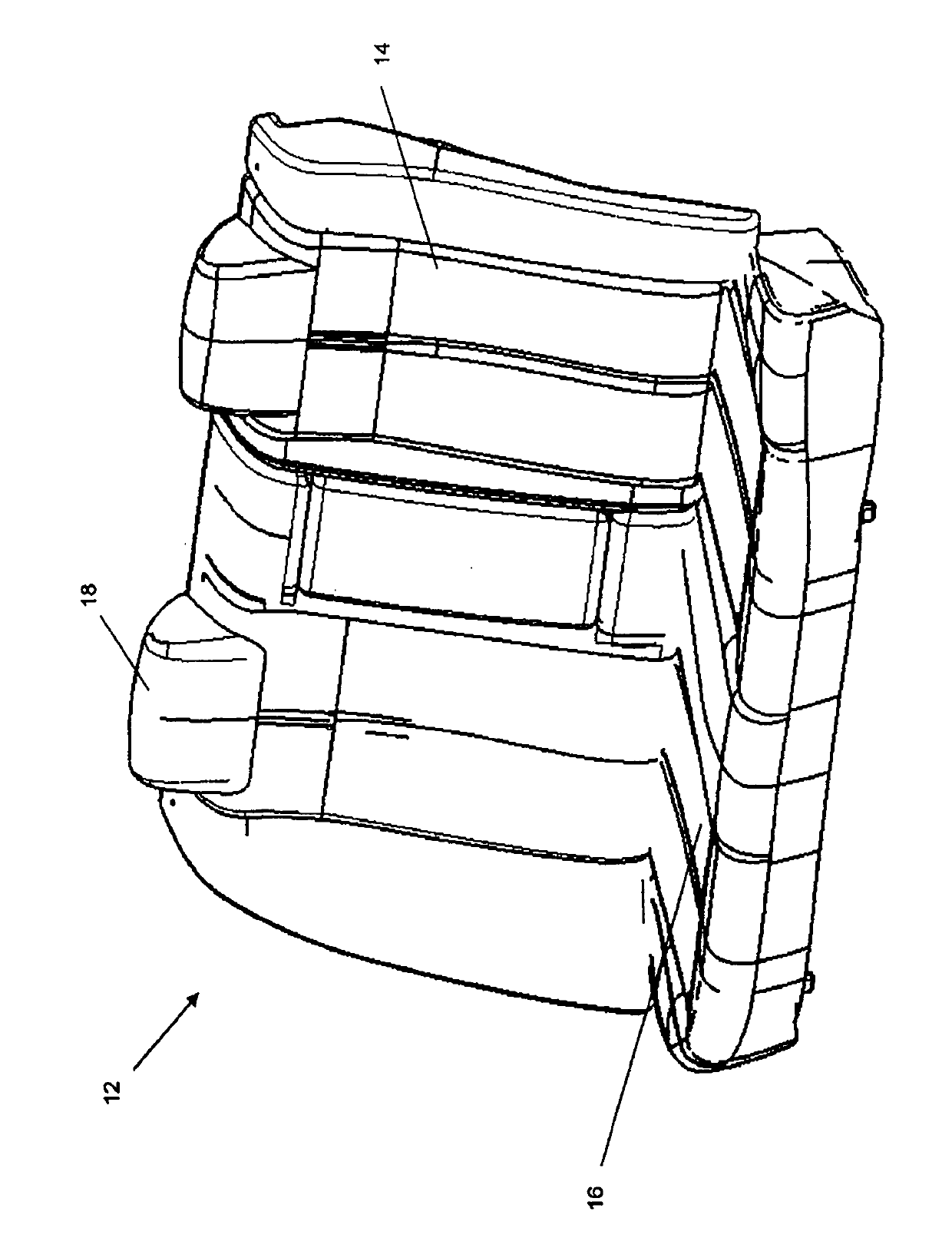

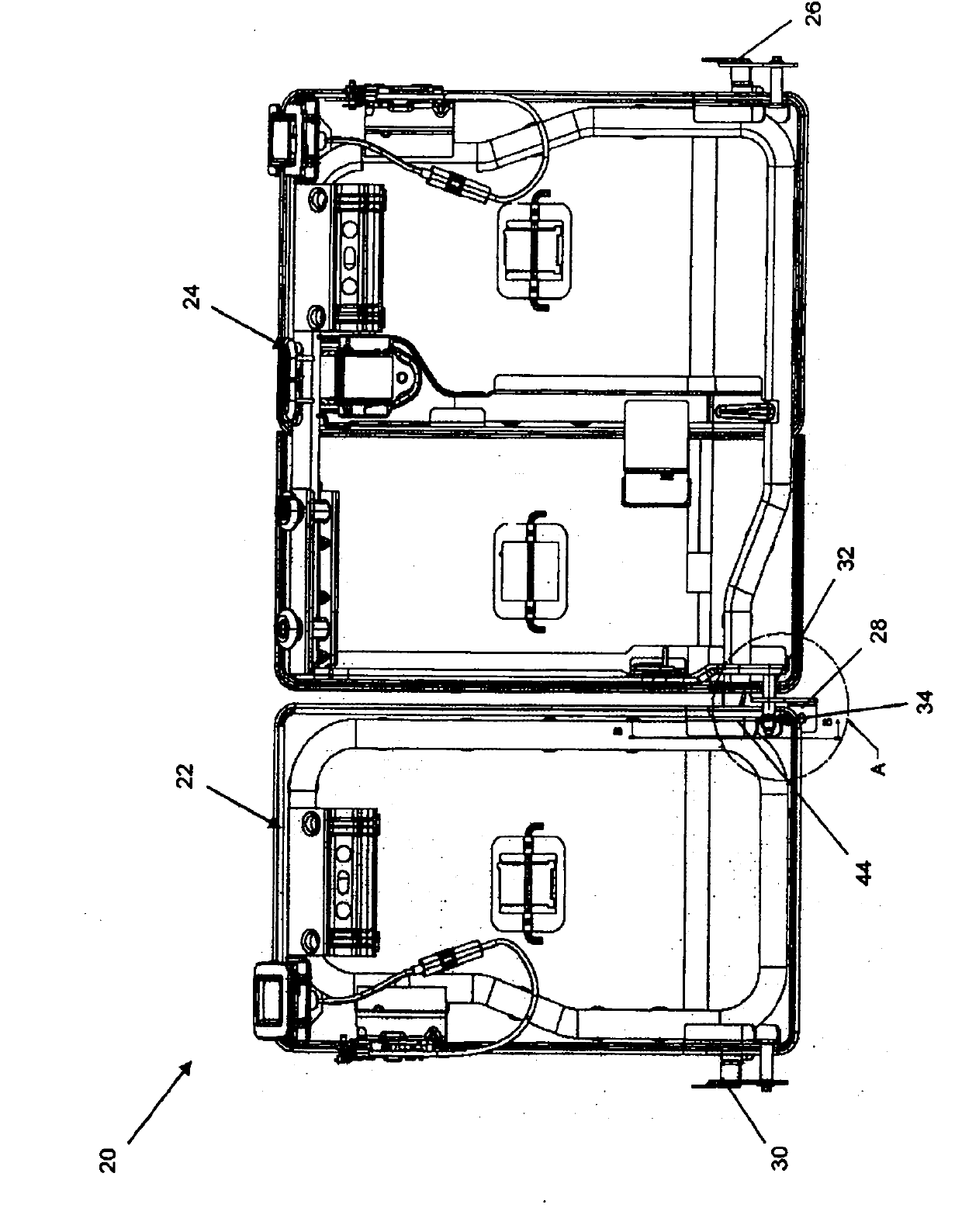

[0017] With reference generally to the drawings and more particularly to figure 1 , shows a vehicle 10 according to an exemplary embodiment. The vehicle 10 includes one or more vehicle seats 12 for occupants of the vehicle 10 . Although the illustrated vehicle 10 is a 4-door sedan, it should be understood that the seat 12 could be used in a minivan, a sport utility vehicle, or in any device in or with which a person travels, Or something is carried in or through these devices to any market; or can be used in applications that include everything from office seating and transportation all the way to airplanes and space travel and everything in between . The illustrated vehicle seat 12 includes a seat back 14 and a seat base 16 . An exemplary embodiment of vehicle structure 12 is at figure 2 shown in . The seat 12 may include a headrest 18 and a seat base portion 16 . A head restraint 18 extends upwardly from the seat back 14 and is configured to restrain the occupant's he...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap