In situ regolith gas recovery system

A regolith and gas technology, applied in solar heating systems, power supply systems for space vehicles, extraterrestrial vehicles, etc., can solve problems such as unpracticality of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

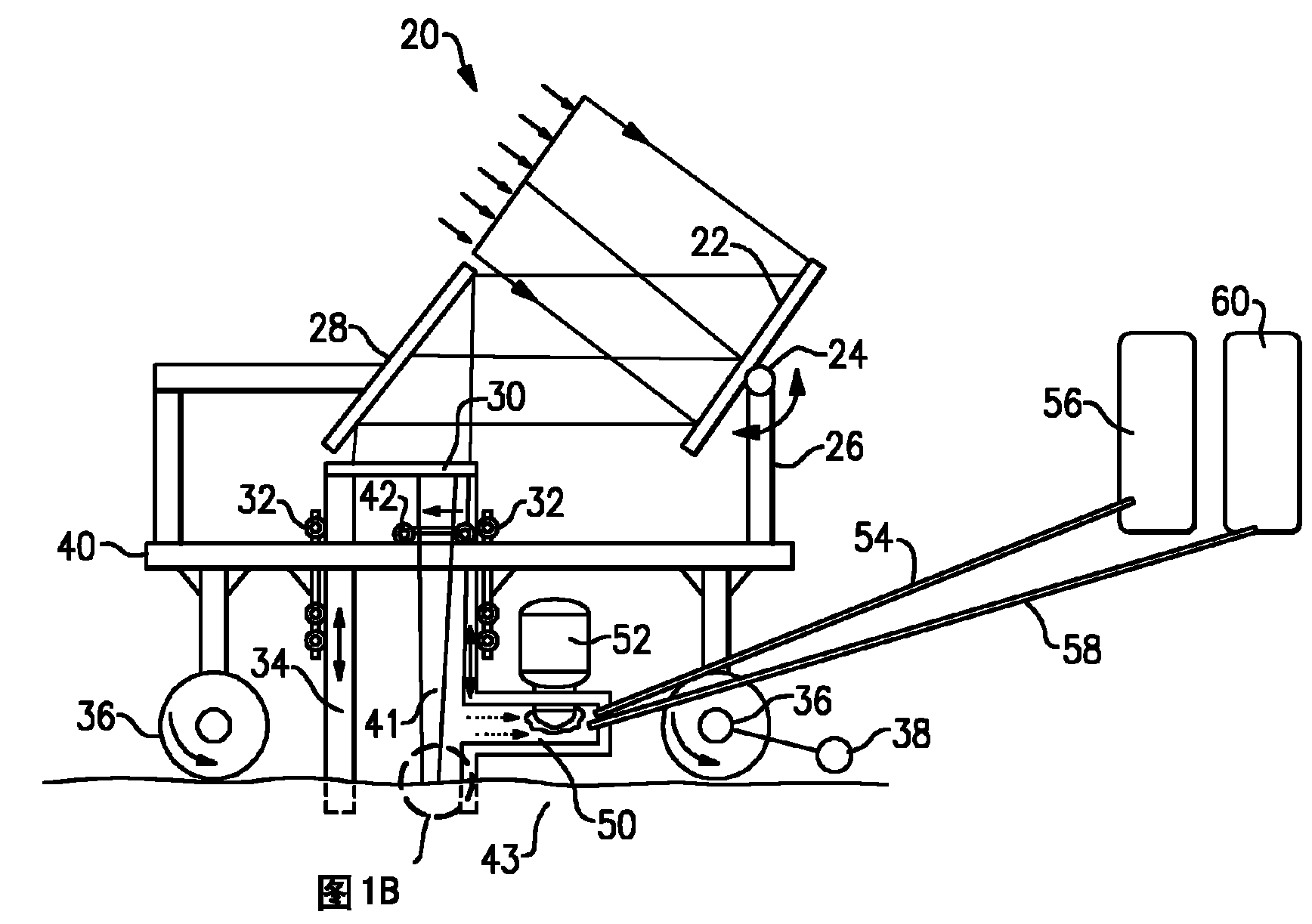

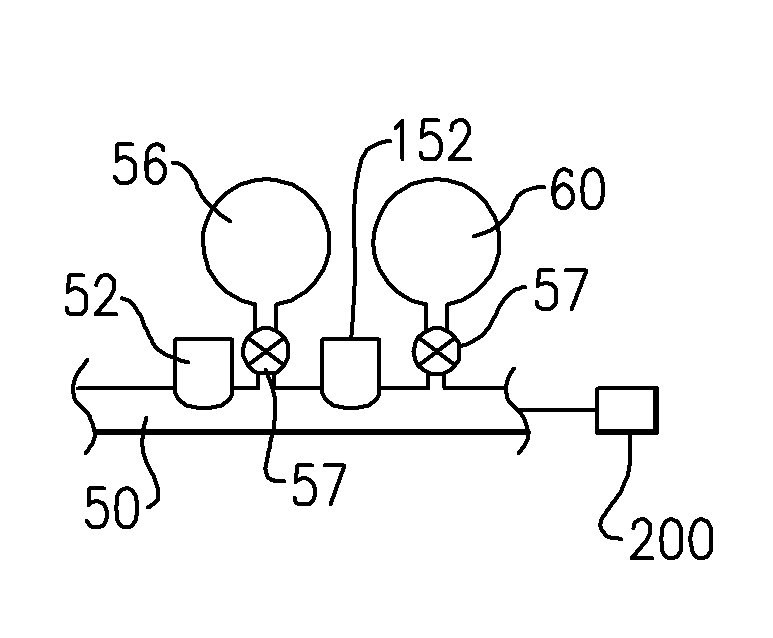

[0014] Figure 1A A system 20 is shown for recovering gas from regolith material 43 such as can be found in the first few meters of the surface of the moon and other space bodies. As shown, the system 20 includes a solar harvesting mirror 22 driven by a motor 24 (shown schematically) mounted atop a support 26 and operable to optimally position the sun's rays (or radiation) and Directed towards another rotating mirror 28 driven by its own motor. The controls for proper alignment of the two mirrors can be as known.

[0015] Focusing lens 30 is mounted on top of movable frame 34 . The movable frame 34 is movable by a motor and guide 32 to translate vertically upward relative to the housing 40 of the system 20 . The wheels 36 are provided with motors 38 (shown schematically) and are operable to move the entire system along the surface.

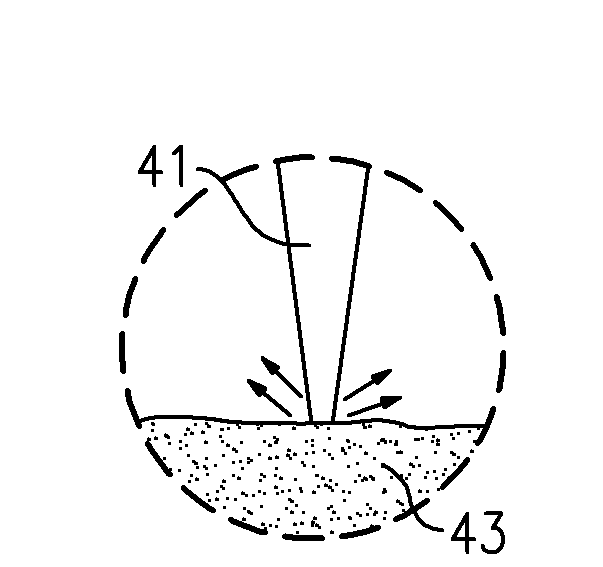

[0016] Lens 30 produces light rays 41 that direct high intensity solar energy onto the outer surface of regolith 43 .

[0017] Lunar regolith...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com