Plasma display panel driving method and plasma display device

A plasma and display panel technology, applied to static indicators, instruments, etc., can solve the problem of not being able to ensure the number of subfields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

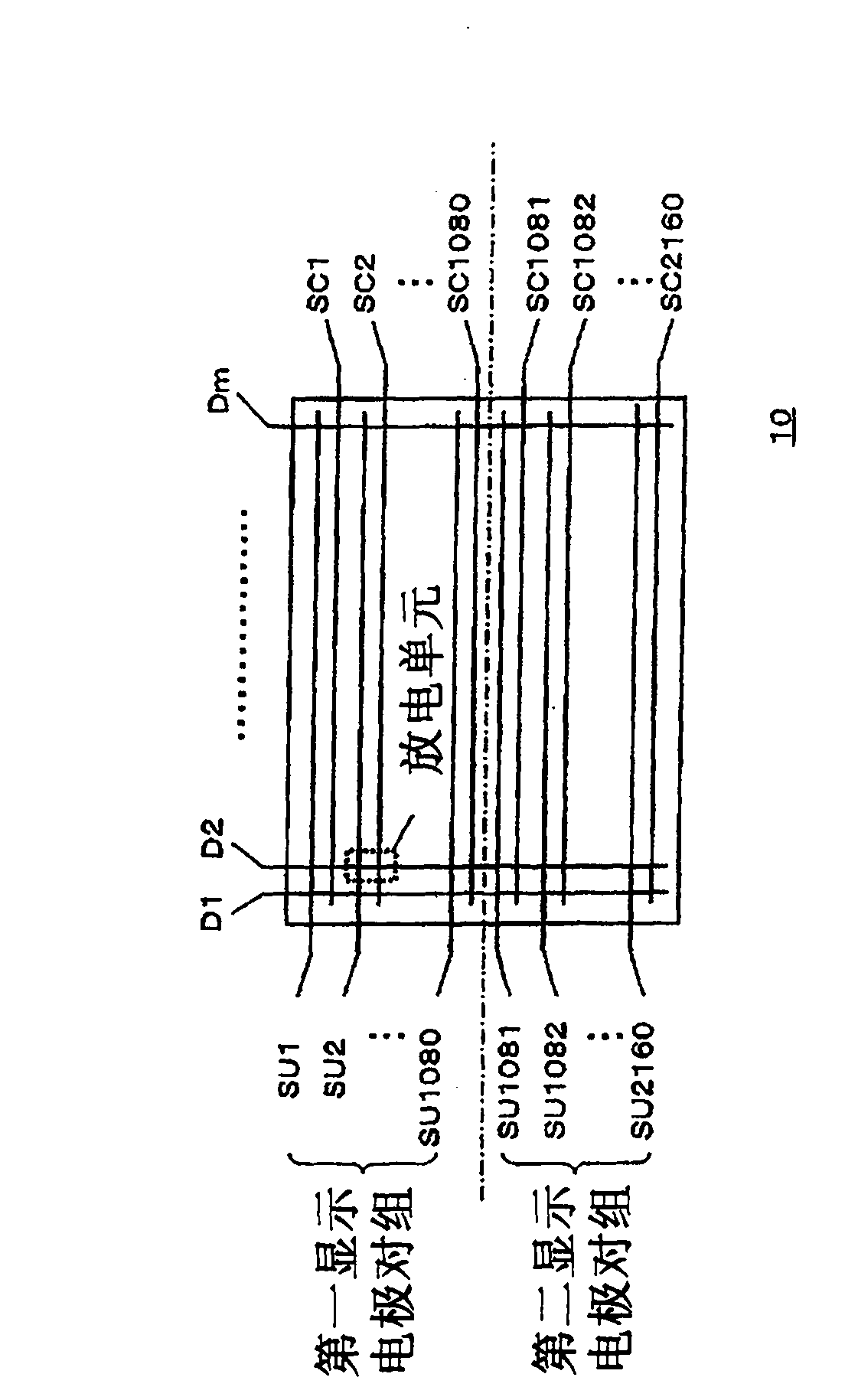

[0080] [Structure of Plasma Display Panel 10]

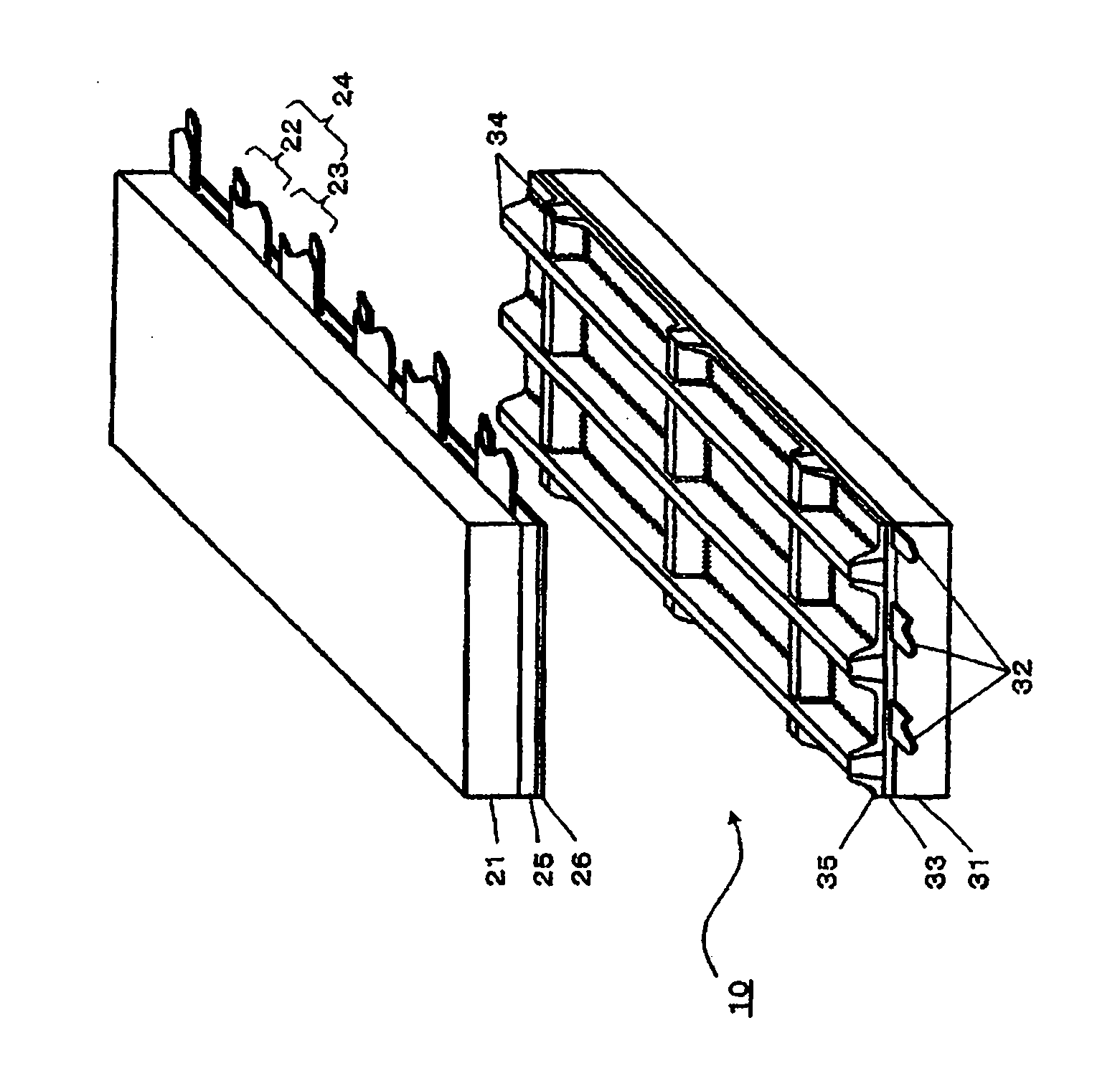

[0081] figure 1 It is an exploded perspective view of plasma display panel 10 of the plasma display device according to Embodiment 1 of the present invention. On front substrate 21 made of glass, a plurality of display electrode pairs 24 including scan electrodes 22 and sustain electrodes 23 are formed. Further, a dielectric layer 25 and a protective layer 26 are sequentially laminated on the front substrate 21 so as to cover the display electrode pairs 24 .

[0082]A plurality of data electrodes 32 are formed parallel to each other on rear substrate 31 . Further, on rear substrate 31 , dielectric layer 33 is formed so as to cover data electrodes 32 , and furthermore, lattice-shaped partition walls 34 are formed thereon. Then, phosphor layers 35 capable of emitting red, green, and blue light are provided in a space formed by the upper surface of dielectric layer 33 and the side surfaces of partition walls 34 .

[0083] Front ...

Embodiment approach 2

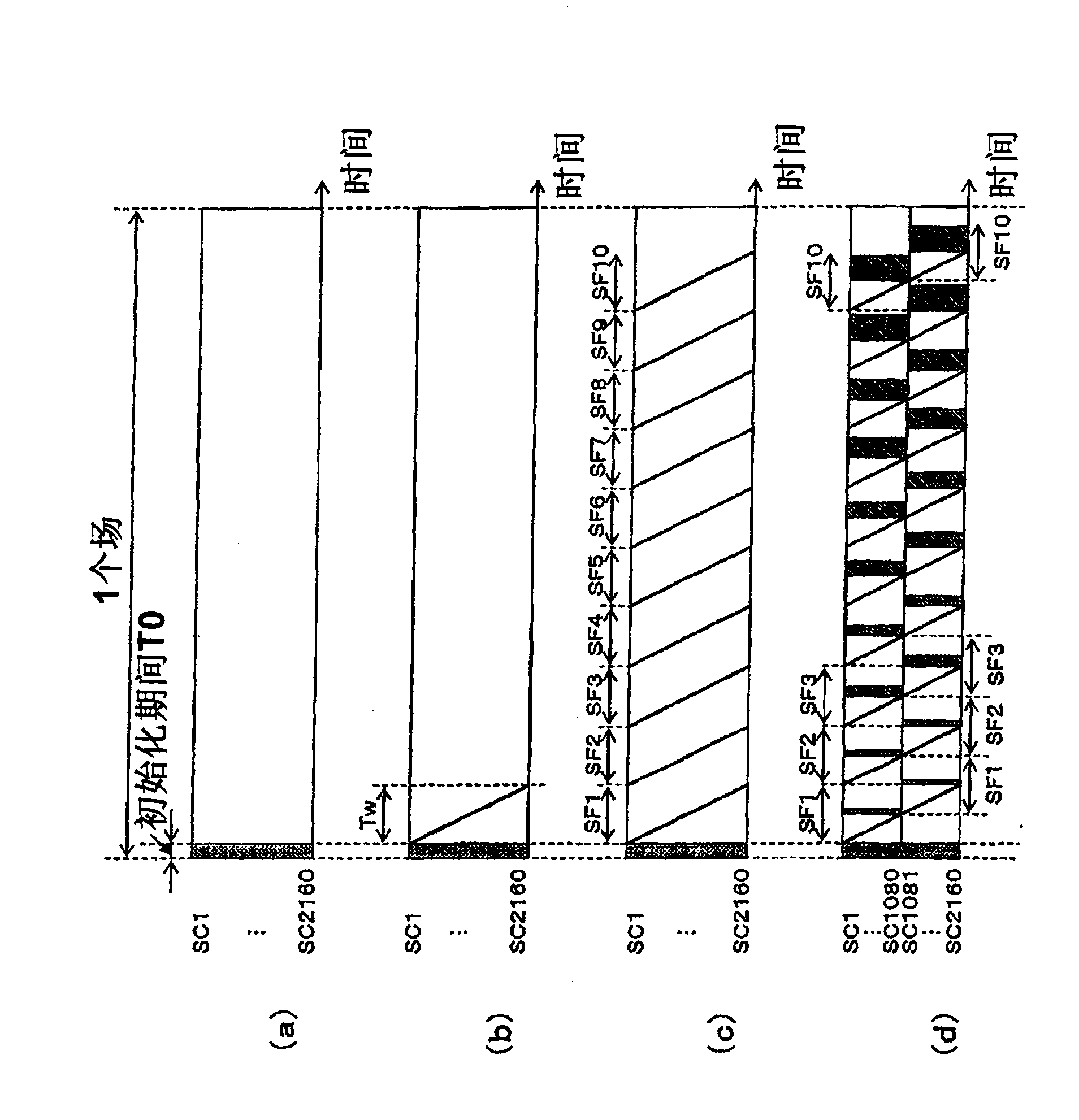

[0224] Figure 11 It is a diagram for explaining the subfield structure applied to the driving method of plasma display panel 10 in the second embodiment. which, with Figure 10 Similarly, the vertical axis represents scan electrodes SC1 to SC2160 , and the horizontal axis represents time. Also, a case where the wall voltage adjustment period is constituted by only the erasing period is shown. Furthermore, the timing of performing the write operation is indicated by a solid line, the sustain period is indicated by hatching from the upper right to the lower left, and the erasing period is indicated by hatching from the upper left to the lower right. The plasma display device in Embodiment 2, and Figure 5 The illustrated Embodiment 1 is the same as that described in Embodiment 1, so description thereof will be omitted.

[0225] The subfield structure of Embodiment 2, and Figure 10 The difference in the subfield structure of Embodiment 1 shown is that luminance weights, th...

Embodiment approach 3

[0233] Figure 12 It is a diagram for explaining the subfield structure applied to the driving method of plasma display panel 10 in the third embodiment. which, with Figure 10 Similarly, the vertical axis represents scan electrodes SC1 to SC2160 , and the horizontal axis represents time. Also, a case where the wall voltage adjustment period is constituted by only the erasing period is shown. Furthermore, the timing of performing the write operation is indicated by a solid line, the sustain period is indicated by hatching from the upper right to the lower left, and the erasing period is indicated by hatching from the upper left to the lower right. The plasma display device in Embodiment 3 is the same as that described in Embodiment 1, so description thereof will be omitted.

[0234] Figure 12 In , the subfield structure in which the subfield with the highest lighting rate is subfield SF8 is shown. The subfield with the highest lighting rate in one field has the largest n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com