Method for driving plasma display panel and plasma display device

A plasma and display panel technology, applied in static indicators, instruments, etc., can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

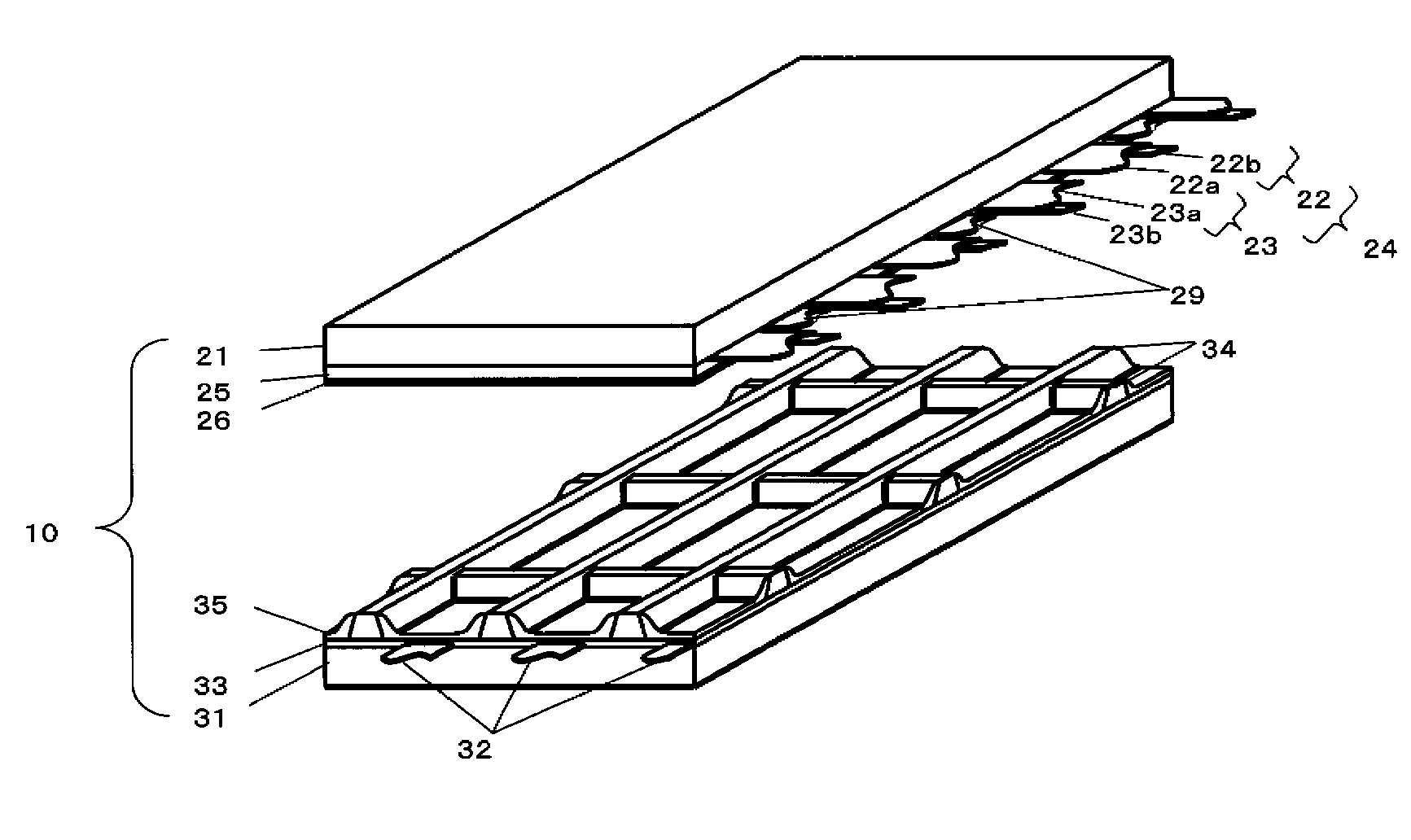

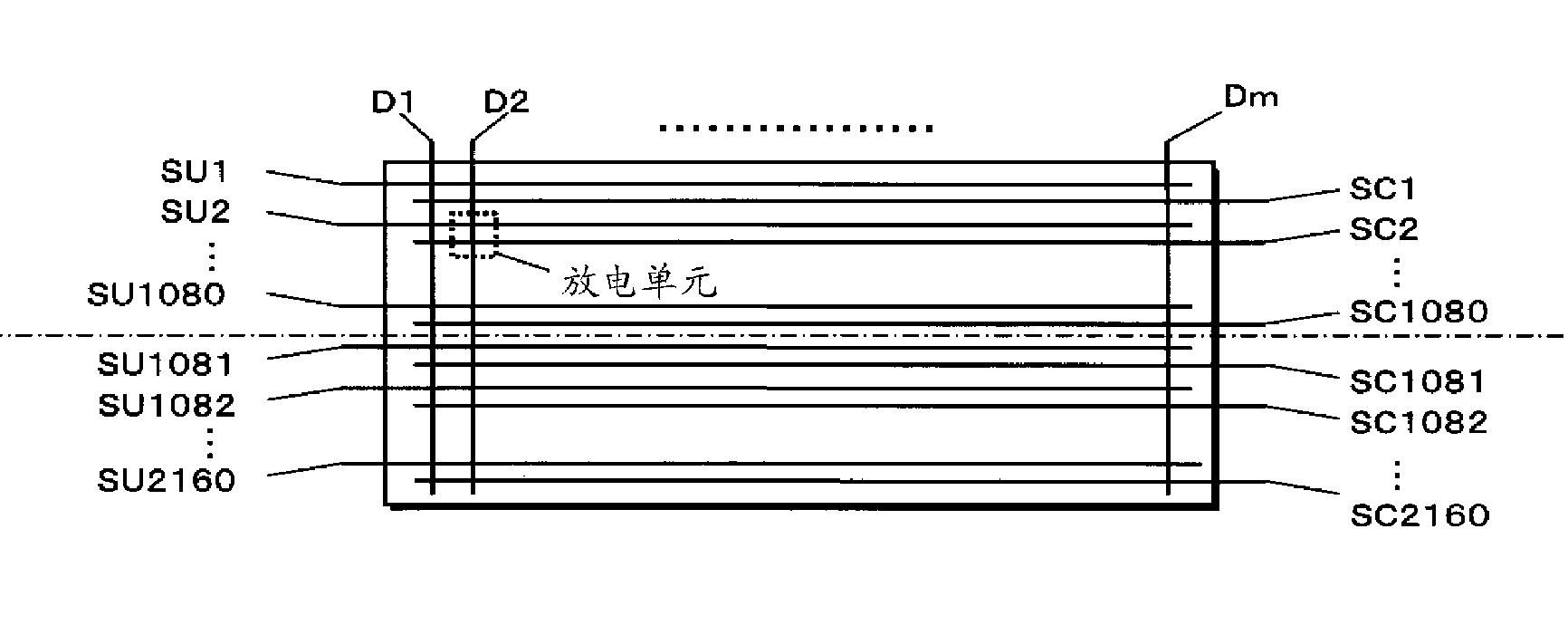

[0046] (panel structure)

[0047] figure 1It is an exploded perspective view showing the structure of the panel 10 used in the first embodiment. A plurality of display electrode pairs 24 including scan electrodes 22 and sustain electrodes 23 are formed on front substrate 21 made of glass. In order to generate discharge and emit light in the discharge gap between scan electrode 22 and sustain electrode 23 forming display electrode pair 24, scan electrode 22 has a large-width transparent electrode 22a, and sustain electrode 23 also has a large-width transparent electrode 23a. Furthermore, bus electrodes 22b, 23b having a small width are stacked at positions away from the discharge gap above transparent electrodes 22a, 23a. Black stripes 29 for shielding light are arranged between adjacent display electrode pairs 24 . In addition, a dielectric layer 25 is formed to cover the scan electrodes 22 , the sustain electrodes 23 and the black stripes 29 , and a protective layer 26 is ...

no. 2 Embodiment approach

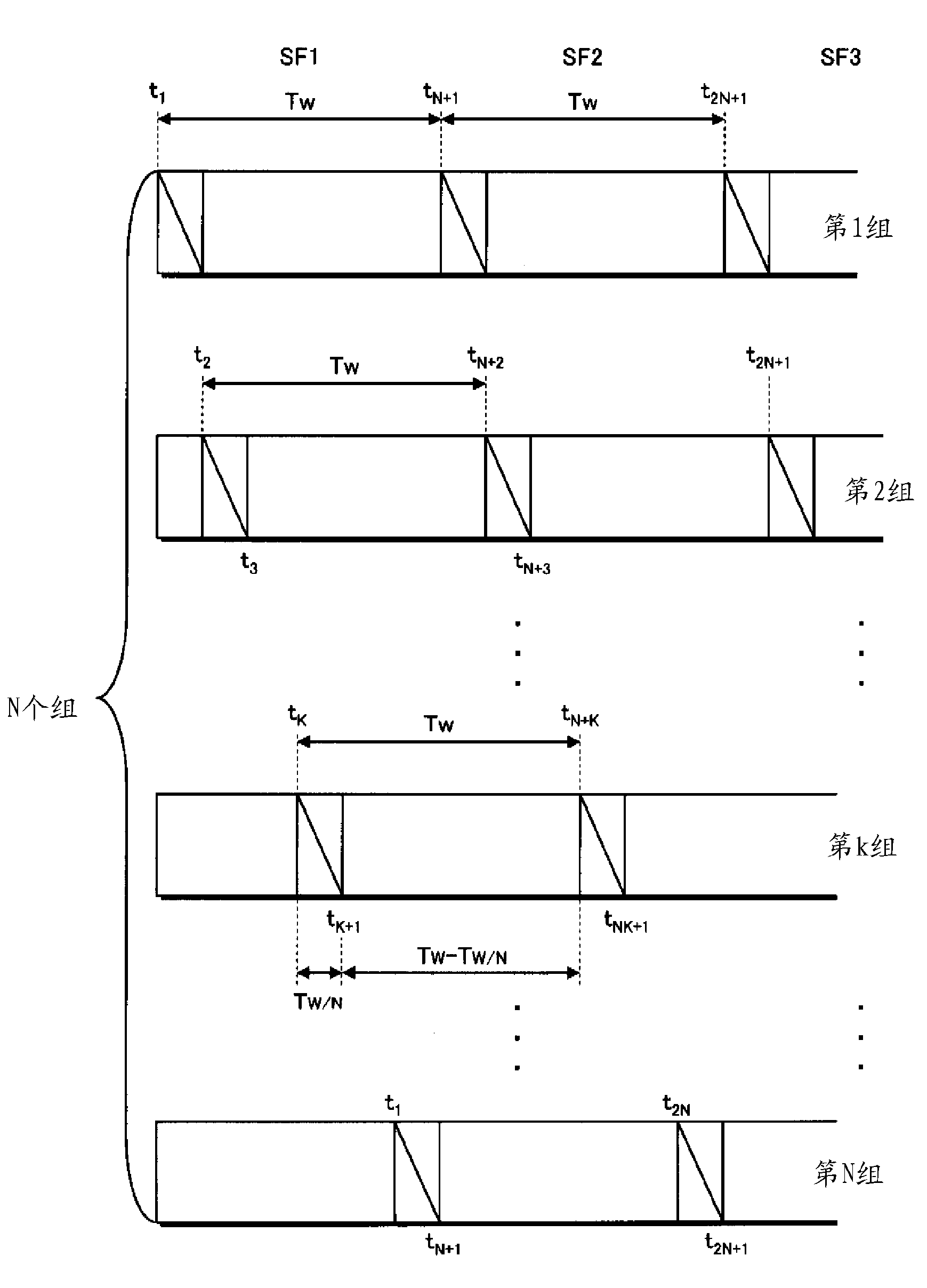

[0139] In the specific example of the above-mentioned first embodiment, the case where the number N of display electrode pairs is 2 is described. Next, the case where the number N of display electrode pairs is set to a larger value will be described.

[0140] In the present embodiment, write driving is performed by the one-shot scanning method similarly to the first embodiment, and the time of one field period is set to 16.7 ms. In addition, it is assumed that the time required for the initialization period is 500 μs, and the time required for the address operation per scan electrode is 0.7 μs. The time Tw required for all the scan electrodes to perform one address operation is 1512 μs. By performing the address operation continuously, 10 subfields can be ensured in one field, which is also the same as in the first embodiment.

[0141] However, in this embodiment, the number of sustain pulses applied in each subfield is set to '110', '81', '55', '33', '20', '11', '6', ' 4', '...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com