Device for reducing towing loss and abrasion of wet dual-clutch

A wet double clutch and clutch technology, which is applied in clutches, friction clutches, mechanically driven clutches, etc., can solve the difficulty of increasing the unevenness and uncertainty of the driven plate slip and wear, and affect the smoothness and ride comfort of the car's shifting process In order to improve the smoothness of gear shifting and ride comfort, avoid premature failure, and simplify the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

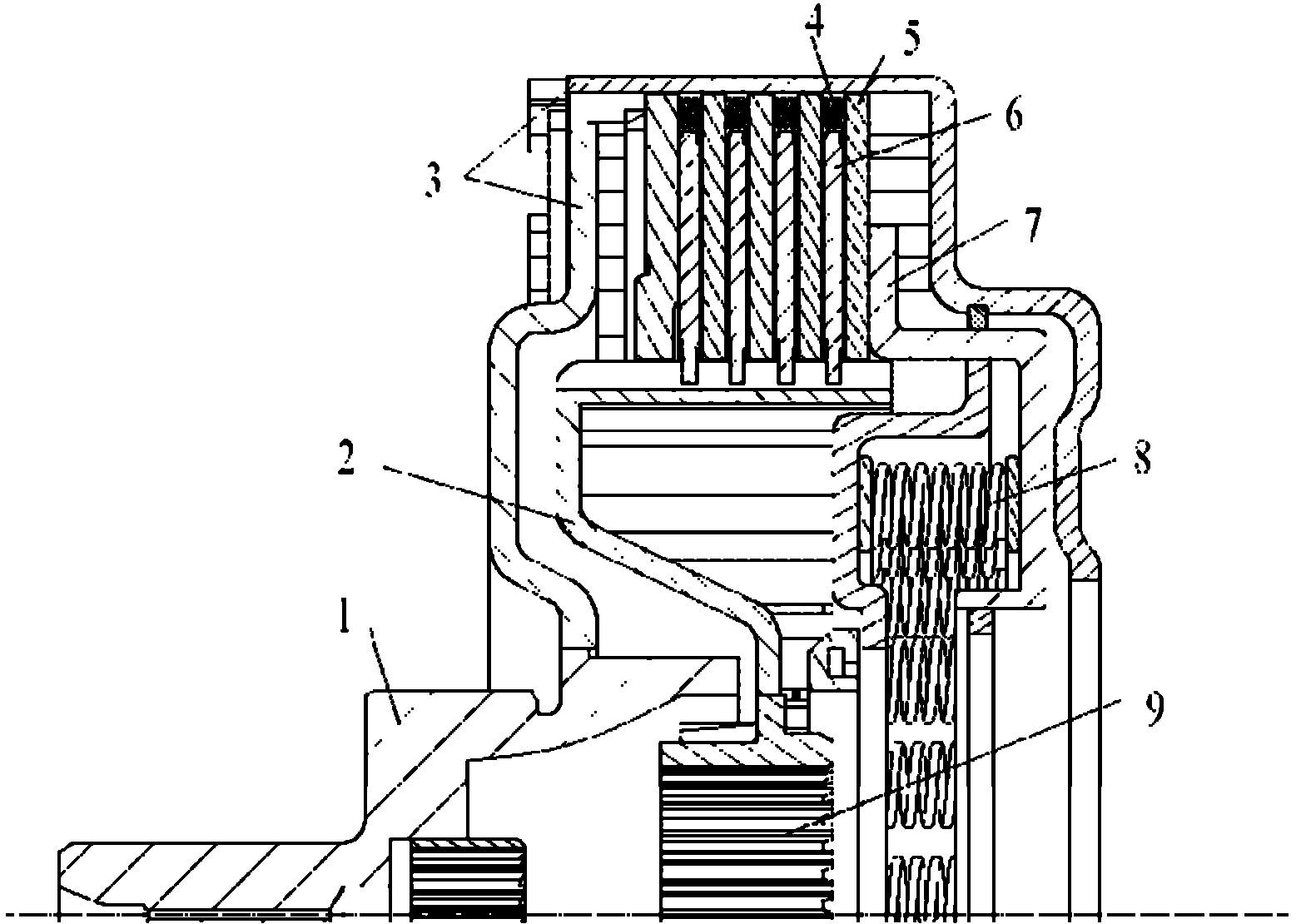

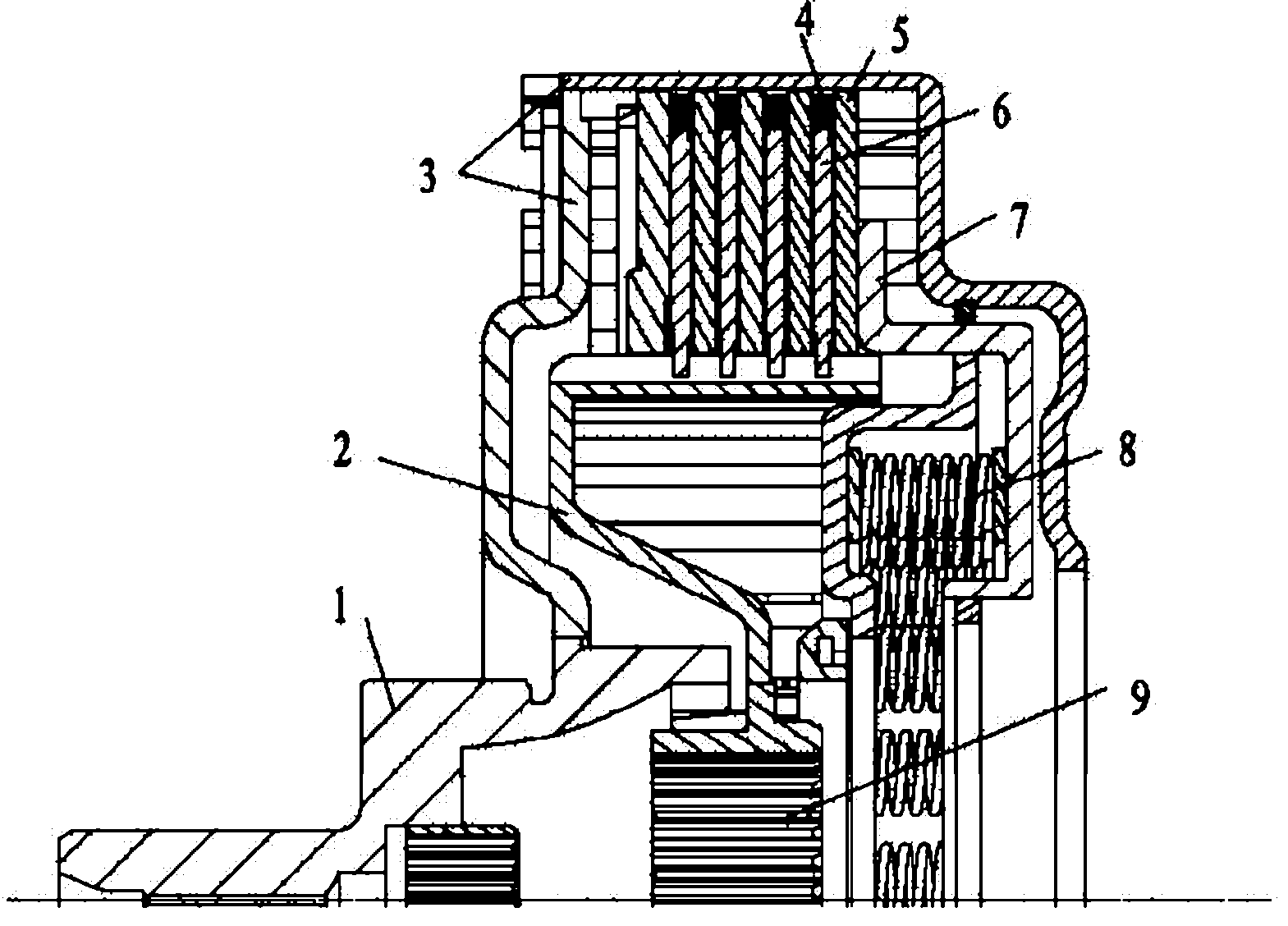

[0011] Such as figure 1 As shown, a device for reducing the loss and wear of the wet double clutch band, including the input shaft 1, the driven plate 2, the clutch housing 3, the driving plate 5, the driven plate 6, the clutch pressure plate 7, the return The spring 8 and the output shaft 9 are characterized in that: the separation spring 4 is distributed along the circumference on the protruding part where the active plate 5 cooperates with the clutch housing 3, and the separation spring 4 is fixed on the active plate 5 by bolts.

[0012] The separation spring 4 of the present invention can be selected according to the distance between the two active plates 5. It can be a helical spring or other elastic elements such as spring plates. The bolt can also be in other ways, as long as the separation spring 4 and the active plate 5 are connected Just fix it.

[0013] The separation spring 4 of the present invention should be three or more, distributed as evenly as possible along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com