Method for processing normal line of paper making felt

A papermaking felt and processing method technology, applied in papermaking, papermaking, textiles and papermaking, etc., can solve the problems of poor color fastness, ambiguity, poor color fastness of standard lines, etc., so as to overcome easy bending deformation and blurring. Unclear, solve uneven color, stable size standard effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

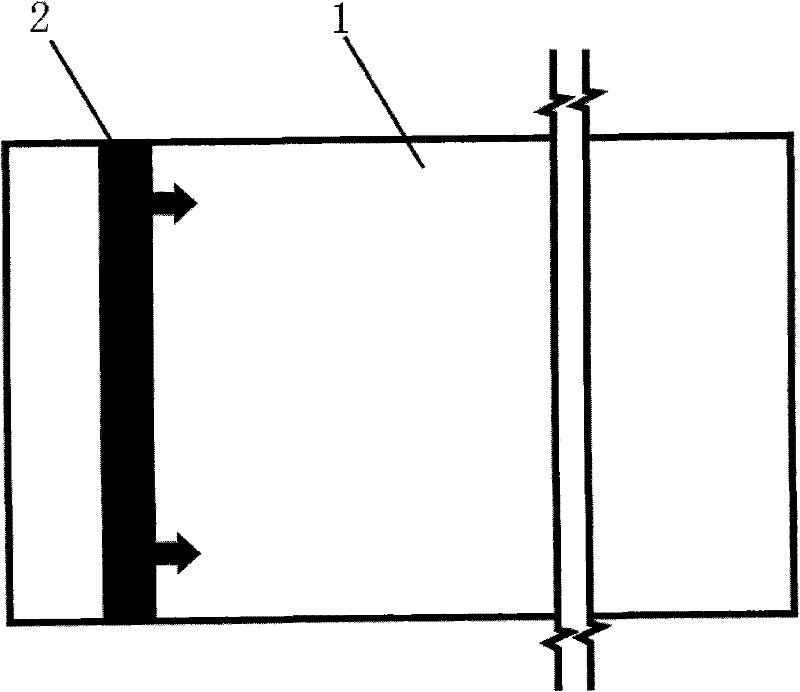

[0011] Such as figure 1 As shown, on the front side of each paper-making felt 1, there is a prominent standard line 2 for initial installation on the machine and correcting alignment during operation. Degree right angles intersect each other, there is an arrow pointing to the running direction at both ends of one side of the standard line 1, the color of the ribbon of the standard line 1 can be bright and remarkable various colors.

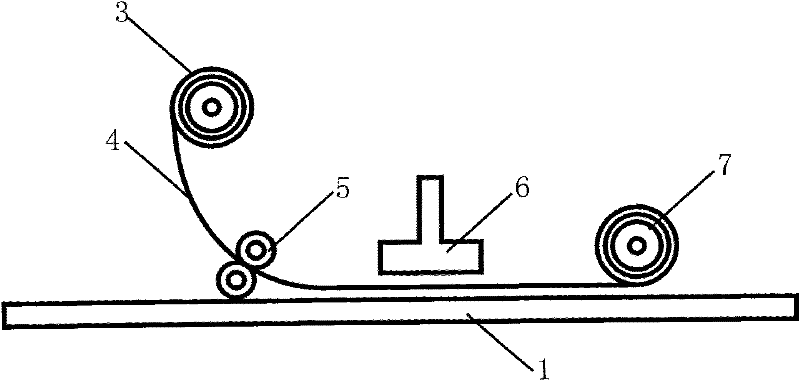

[0012] figure 2 In order to print the principle diagram of the thermal transfer stamping machine of the papermaking felt standard line of the present invention, a papermaking felt standard line processing method of the present invention is to print a 20-40 cm wide hot stamping machine with a brand logo and an arrow direction. Sensitive color ribbon 4 is installed in the thermal transfer printing ironing machine, and the thermal transfer printing ironing machine is evenly moved, and the thermal sensitive color ribbon 4 installed on the unwinding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com