Preparation method of flexible copper-indium-gallium-selenide thin-film solar cell monolithic integrated assembly

A technology of thin-film solar cells and copper indium gallium selenide, which is applied in the field of solar cells, can solve the problems of increased module dead area, reduced module efficiency, and difficulty in precise positioning, and achieve the effect of avoiding the difficulty of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

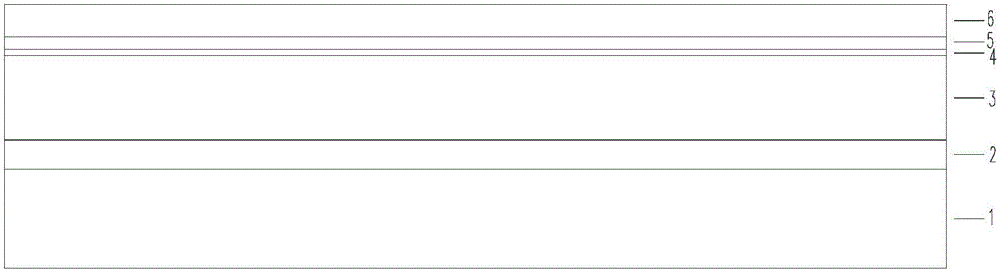

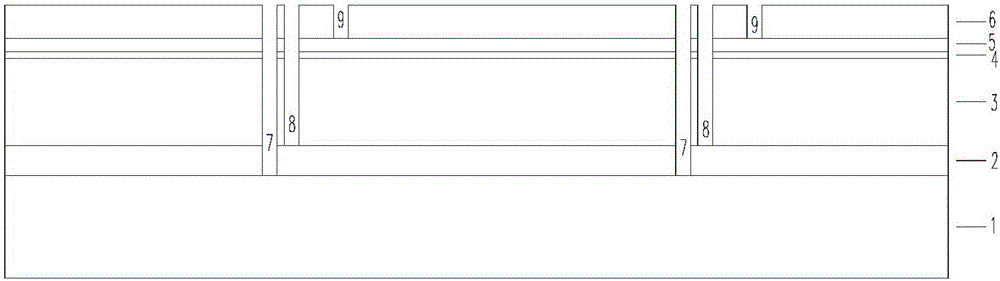

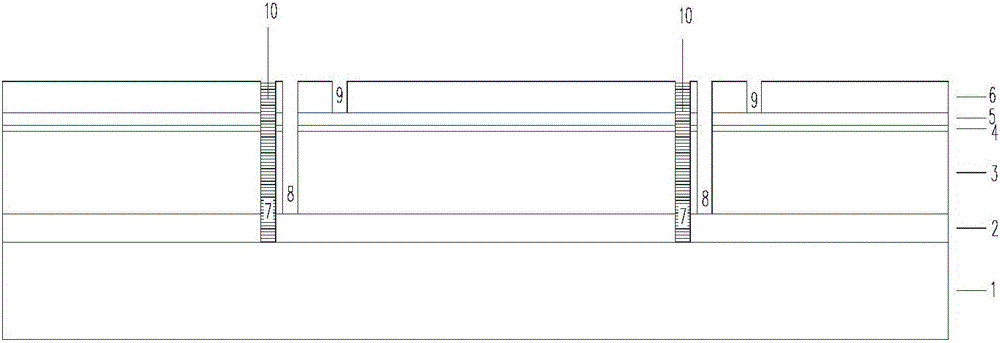

[0029] see Figure 1 to Figure 5 , a method for preparing a flexible copper indium gallium selenide thin film solar cell monolithic integrated assembly, the flexible copper indium gallium selenide thin film solar cell sequentially comprises: a substrate 1, a back electrode layer 2, an absorption layer 3, a buffer Layer 4, high resistance layer 5, transparent conductive layer 6; including the following steps:

[0030] Step 101: Etch at least one set of channels and insulating wire channels 12 on the flexible copper indium gallium selenium thin film solar cell from top to bottom by laser etching method, each set of channels includes the first channel 7, the second channel The channel 8 and the third channel 9; the first channel 7, the second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com