Processing process of piston cylinder sleeve

A processing technology, a technology of piston and cylinder, applied in the field of processing technology of piston cylinder liner, can solve the problems of inaccurate process requirements, poor product quality, and insufficiently precise process flow, and achieve a precise process flow, high product quality, and high processing precision. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

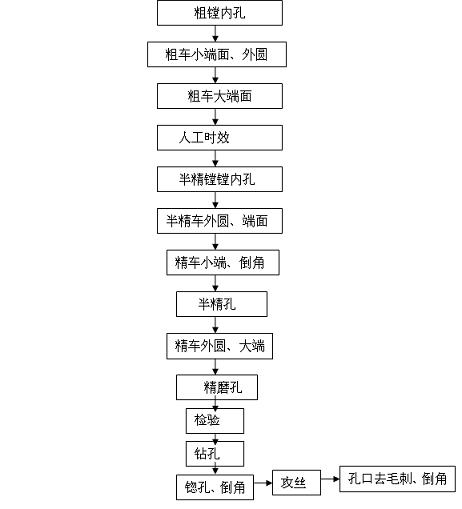

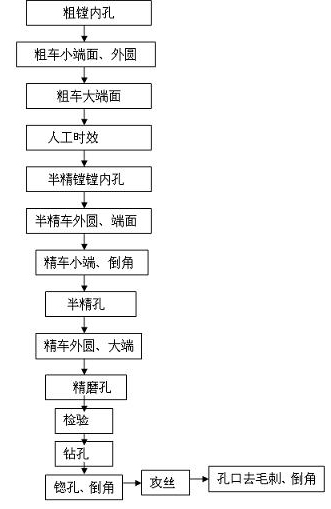

[0024] Such as figure 1 As shown, the piston cylinder liner processing technology of the present invention includes the following steps: step a, rough boring inner hole; step b, rough turning small end face and outer circle; step c, rough turning large end face; step d, artificial aging; step e , semi-fine boring and boring the inner hole; step f, semi-finishing the outer circle and end face; step g, finishing small end and chamfering; step h, semi-finishing the hole; step j, finishing turning the outer circle and large end face; step k , fine grinding hole; step L, inspection; step m, drilling; step n, countersinking, chamfering; step o, tapping; step p, hole deburring, chamfering; In a furnace with a temperature lower than 205°C, heat the casting slowly, and keep it at 592±27°C for at least 2 hours. Calculate the holding time according to the maximum central section size of the casting. Every 25mm needs to be kept warm for 1 hour to calculate the holding time. Cool in the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com