Anti-skidding booster for tyre to climb

A technology of boosters and tires, applied in anti-skid devices, tire parts, transportation and packaging, etc., can solve problems such as unsatisfactory, time-consuming and labor-intensive anti-skid effects, and great influence on driving speed, so as to increase grip and friction. , The effect of improving anti-skid performance and driving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

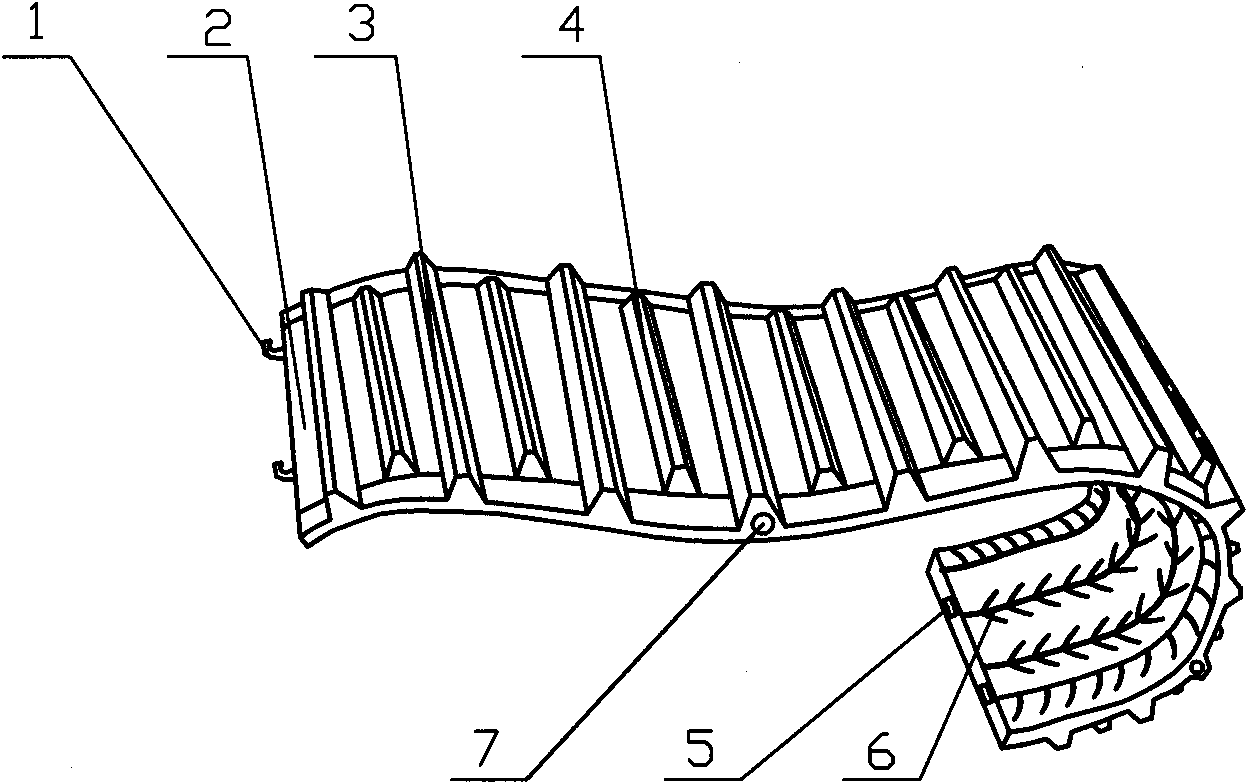

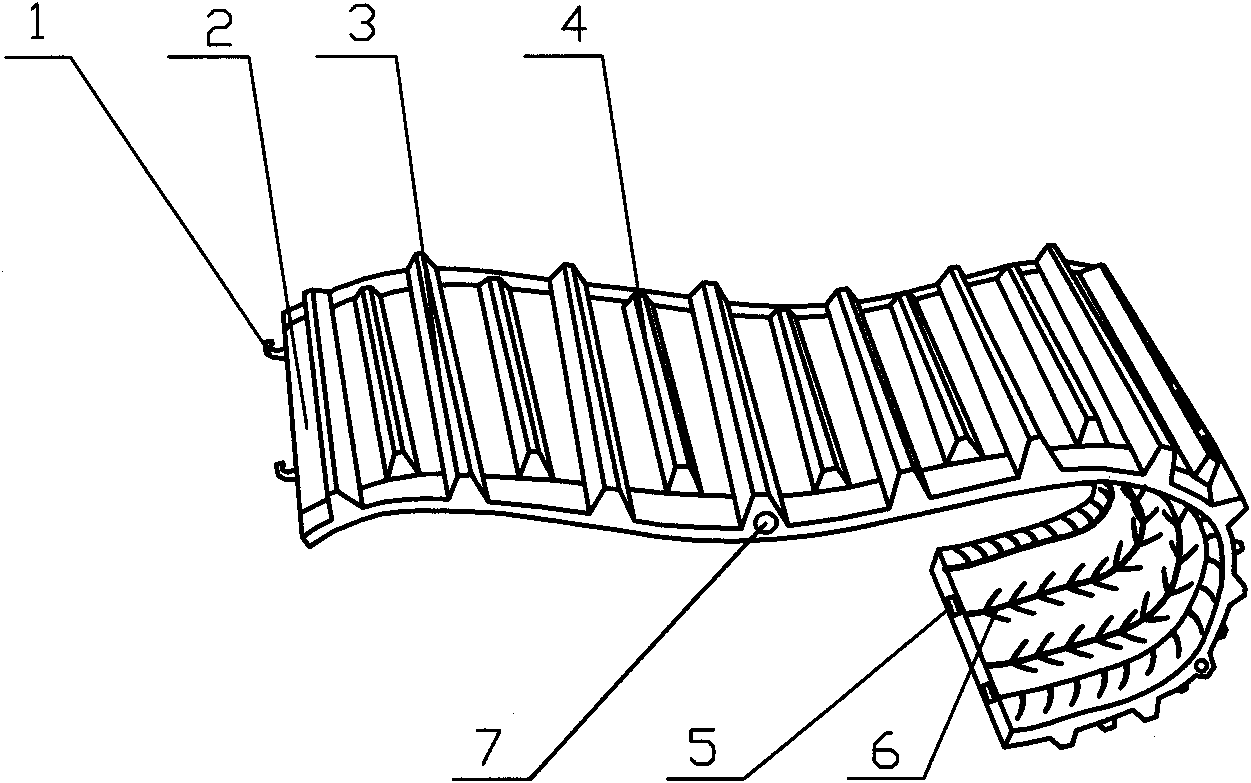

[0018] Such as figure 1 As shown, a tire climbing anti-skid booster, its main body is a matrix 2 wrapped on the outside of the tire, the matrix 2 is a belt made of rubber material, the two ends of the matrix 2 are designed as plug-in locking mechanisms, the upper surface of the matrix is In order to be in contact with the ground, the upper surface is evenly designed with rubber strips integrated with the substrate 2 and perpendicular to the length direction of the substrate. The rubber strips are long rubber strips 3 and short rubber strips 4 arranged at intervals, long rubber strips 3 and short rubber strips 4 There is a difference in height. The lower surface of the substrate is the contact surface with the tire, and the anti-skid texture 6 corresponding to the tread pattern of the tire is regularly distributed on the lower surface. A plurality of anti-off rope buckles 7 are designed on the side of the base body 2, and the anti-off rope buckles are symmetrical in pairs on t...

Embodiment 2

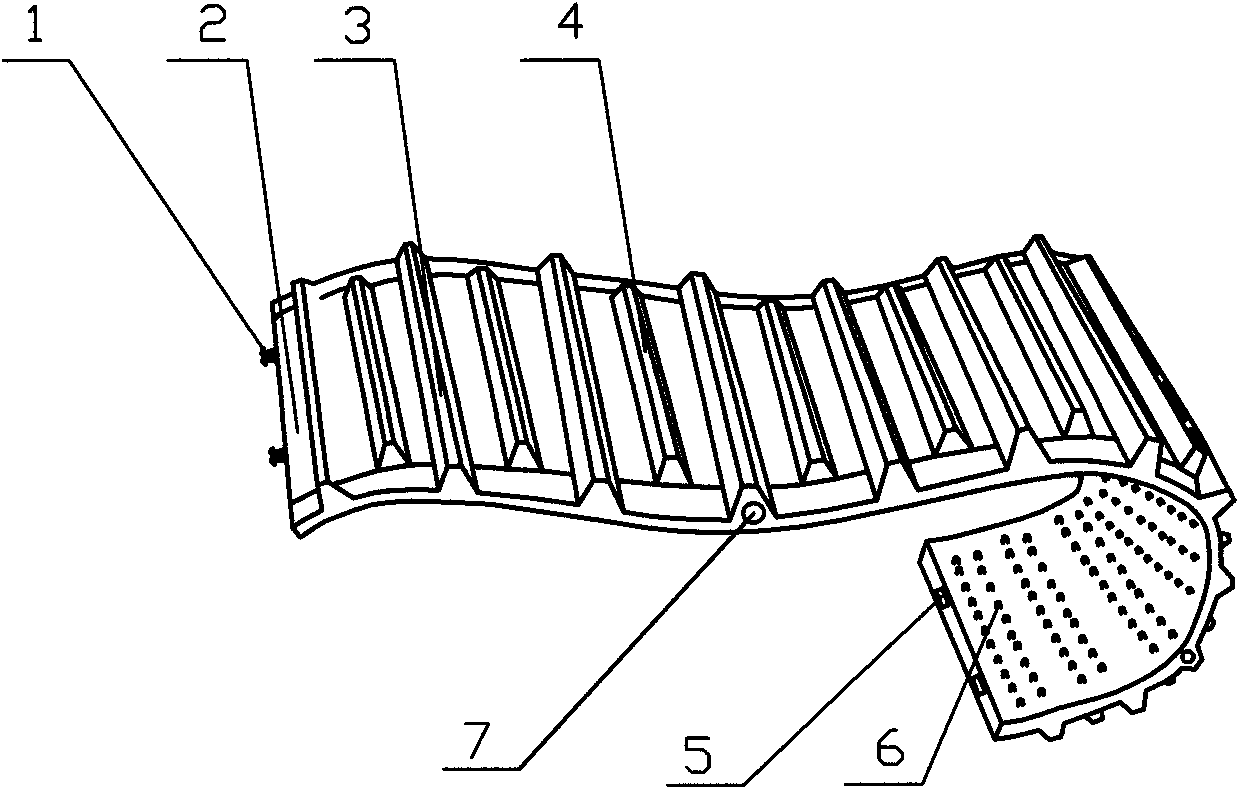

[0020] in such as figure 2 In the shown embodiment, the main structural features are the same as in Embodiment 1, the difference lies in: 1, the lock head. Embodiment 1 uses a one-way curved lock head, but this embodiment uses a two-way curved lock head. 2. Non-slip texture. The anti-skid texture in this embodiment is dot-like protrusions uniformly distributed in the lateral direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com