Feeding device used for vacuum forming machine

A vacuum forming machine and tablet technology, applied in the field of home appliance manufacturing equipment molds, can solve problems such as low efficiency and achieve the effect of preventing heavy materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

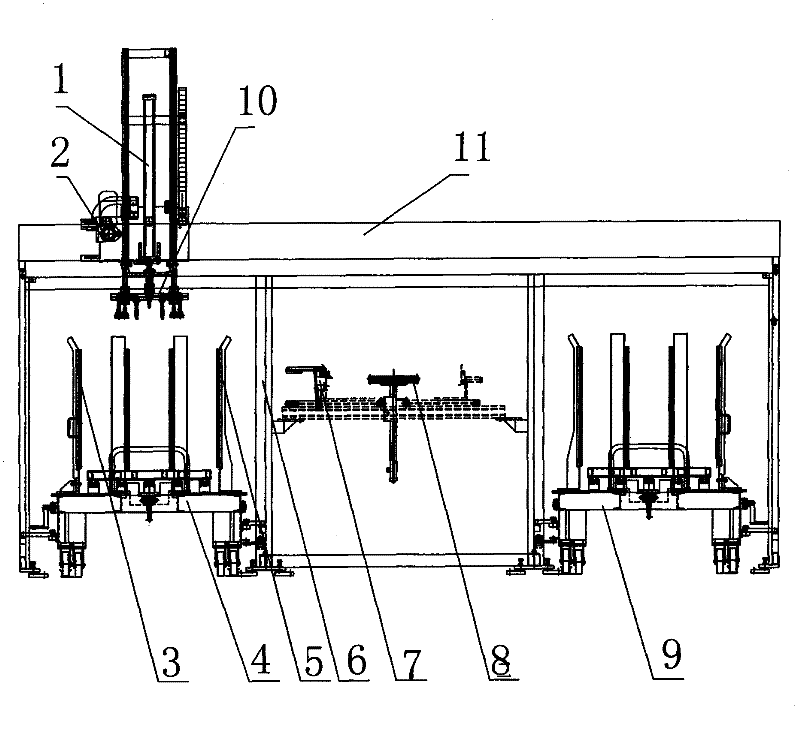

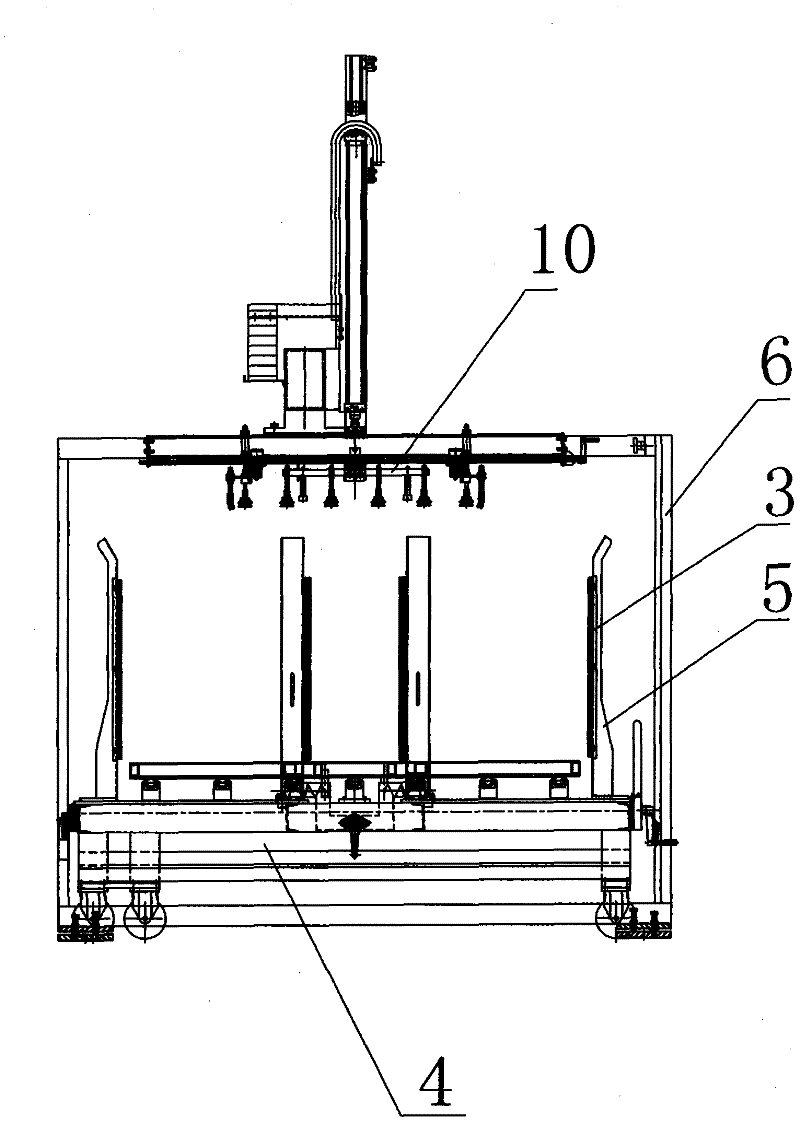

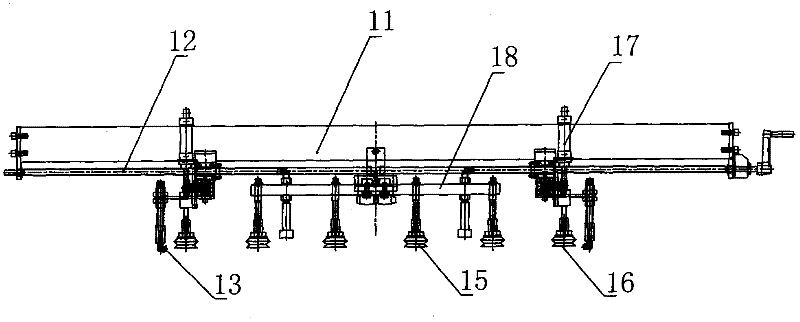

[0016] combine figure 1 , figure 2 , image 3 and Figure 4 As shown, the feeding device for the vacuum forming machine in this embodiment includes a stacking trolley, a material suction manipulator and a control unit. In this embodiment, two sets of left and right stacking trolleys are equipped, namely trolley stacking trolley 4 and stacking trolley 9. To ensure that the vacuum forming machine does not stop due to lack of materials to improve production efficiency. by figure 1 Take the stacking trolley on the left as an example. Each set of stacking trolleys includes a trolley body 4, a material positioning column 5 arranged on the trolley body 4, and whether there is a sensing element for the material. The material positioning column 5 is along the edge of the trolley body. Eight are symmetrically arranged, and the tablet positioning column 5 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com