Crank type valve driving device

A driving device and crank-type technology, which is applied in the field of valve manufacturing, can solve the problems of uncontrollable opening and closing angles, excessive adjustment, and inability to adjust opening and closing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

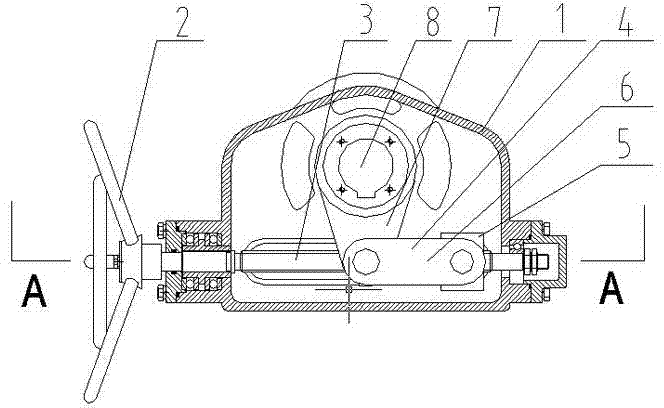

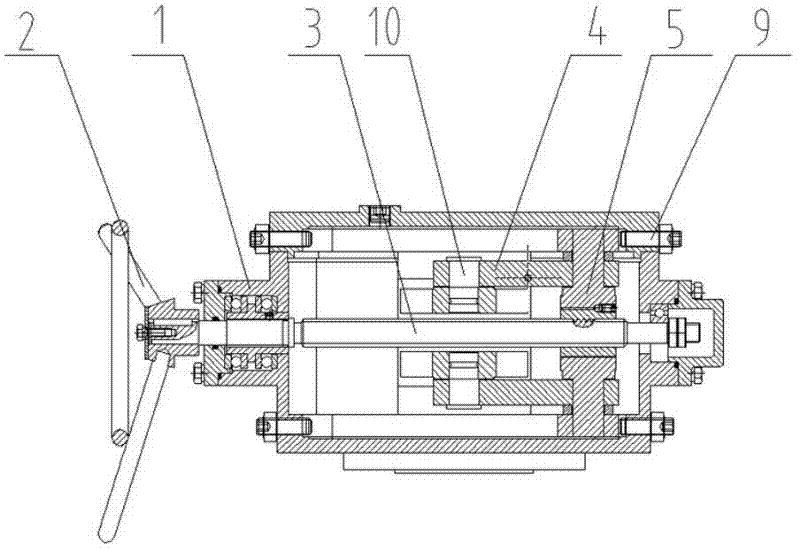

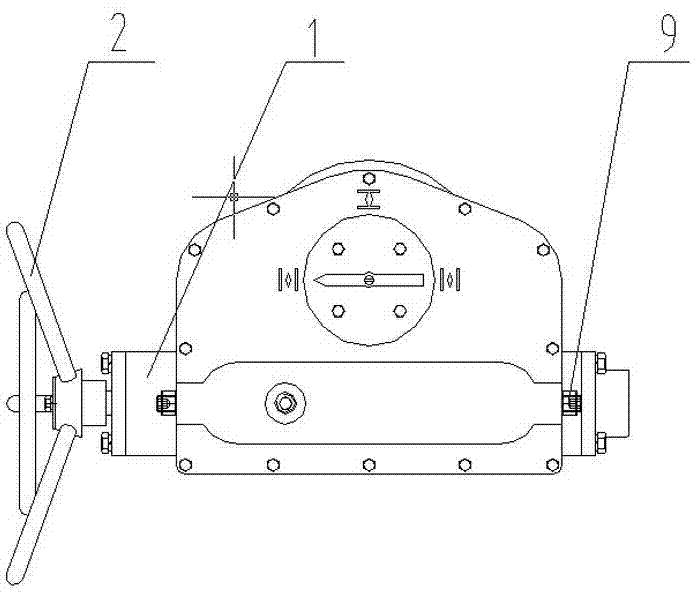

[0011] Such as figure 1 , 2 As shown, the bellcrank type valve driving device includes a box body 1, a hand wheel assembly 2, a screw rod 3, a swing arm 4, and a valve rod 8. Both ends of the screw rod 3 are respectively connected to the box body 1 through bearings, and the hand The wheel assembly 2 is fixedly connected to the left end of the screw mandrel 3, and the nut sleeve 5 is threaded on the screw mandrel 3; the swing arm 4 includes a first swing arm 6 and a second swing arm 7, and the first swing arm 6 is fixedly connected to the nut sleeve 5 Above, the first swing arm 6 is parallel to the screw rod 3, one end of the second swing arm 7 is hinged to the left end of the first swing arm 6 through a support pin 10, and the other end of the second swing arm 7 is fixedly connected to the swing arm 4 and is perpendicular to The valve stem 8 is provided with mechanical stop bolts 9 at the left and right ends of the upper part of the box body 1 respectively. Set the mechanica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com