Car heater water tank with movable inflow and outflow pipes

A technology of outflow pipes and warm air, applied in lighting and heating equipment, heat exchange equipment, heat exchanger shells, etc. to avoid fatigue fracture failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

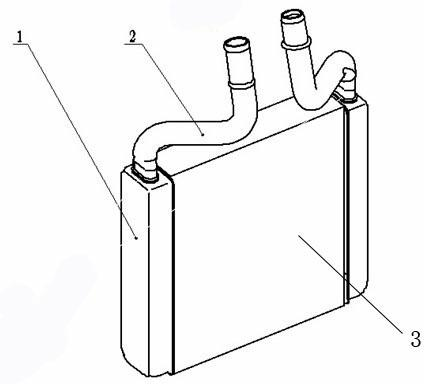

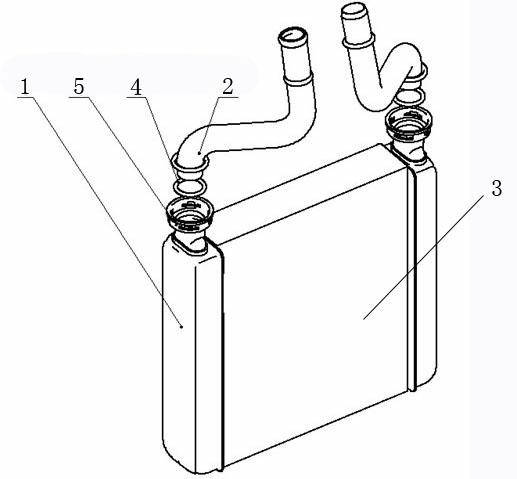

[0016] Further illustrate the structure of this water tank below in conjunction with accompanying drawing:

[0017] see figure 2 , the warm air water tank includes a core body 3, a water chamber 1, a sealing jacket 5, an O-ring 4 and an inflow and outflow pipe 2, and the inflow and outflow pipe 2 passes through the sealing jacket 5 and the O-ring 4 to enter and exit the water chamber. The nozzle is connected and sealed. In this structure, the sealing jacket 5 is used as a transition piece, welded on the inlet and outlet of the water chamber, and the inflow and outflow pipe 2 and the O-ring 4 are assembled with it.

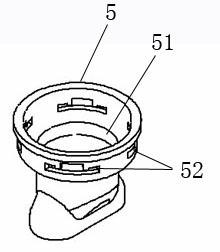

[0018] see image 3 , the center of the sealing jacket 5 is a passage through up and down, a circle of bosses 51 are arranged in the middle of the inner wall of the sealing jacket, and several notches 52 are uniformly opened on the upper part of the sealing jacket in the circumferential direction.

[0019] see Figure 4 and Figure 5 , On the outer wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com