Automobile Exhaust Muffler

A technology for automobile exhaust and muffler, which is applied to exhaust devices, mufflers, machines/engines, etc., can solve the problems of fatigue fracture failure, abnormal noise, and low strength of the muffler inner tube, and achieves a simple structure. , low manufacturing cost, enhanced strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further detailed below with reference to the accompanying drawings:

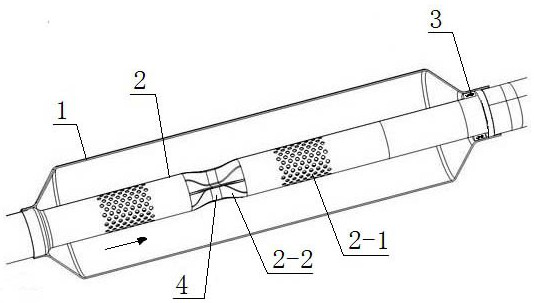

[0016] like figure 1 A car exhaust muffler, including a muffler in the muffler of the silencer portion 2-1, and a muffler having a muffler on the tube wall of the muffler portion 2-1, and the muffler insertion 2 is fitted with a muffler case. Body 1, gap in the muffler housing 1 and the muffler 2 between the tubing 2. The muffler inside the intubation 2 has a reinforcing tube portion 2-2 that is separated into two sections of the muffler portion 2-1, and the reinforcing tube portion 2-2 is equipped with a reinforcing rib 4; the middle portion of the reinforcing pipe portion 2-2 is contracted into the diameter. Small than the diameter of the silence pipe portion, the reinforcing rib 4 is located in the middle of the shrink portion and surrounds the outside of the shrink portion. The two ends of the muffler housing 1 are respectively provided with a reduction portion connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com