Frictional abrasion tester used for abrasion in-site measurement

A technology of in-situ measurement and wear test, used in measuring devices, testing wear resistance, using mechanical devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

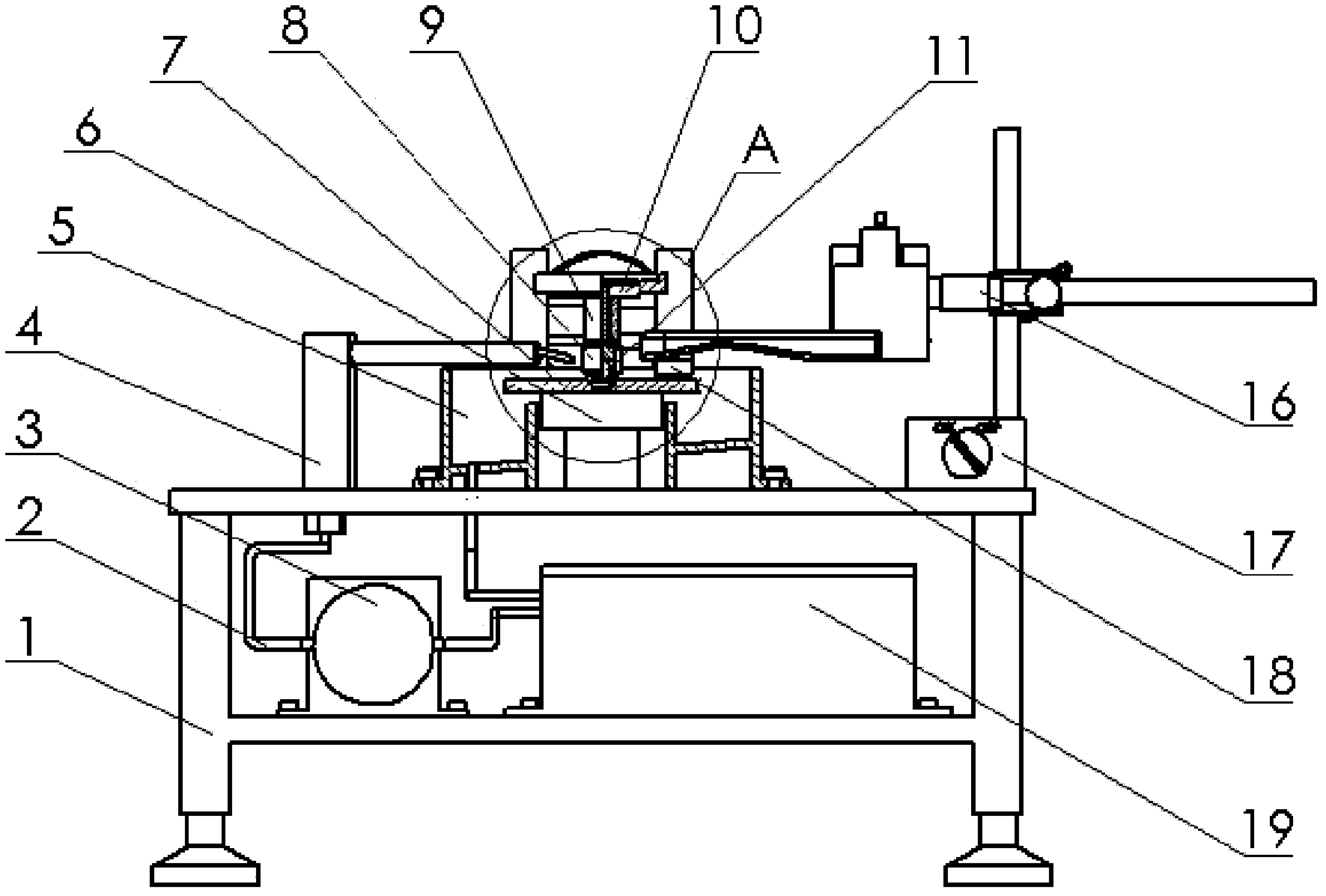

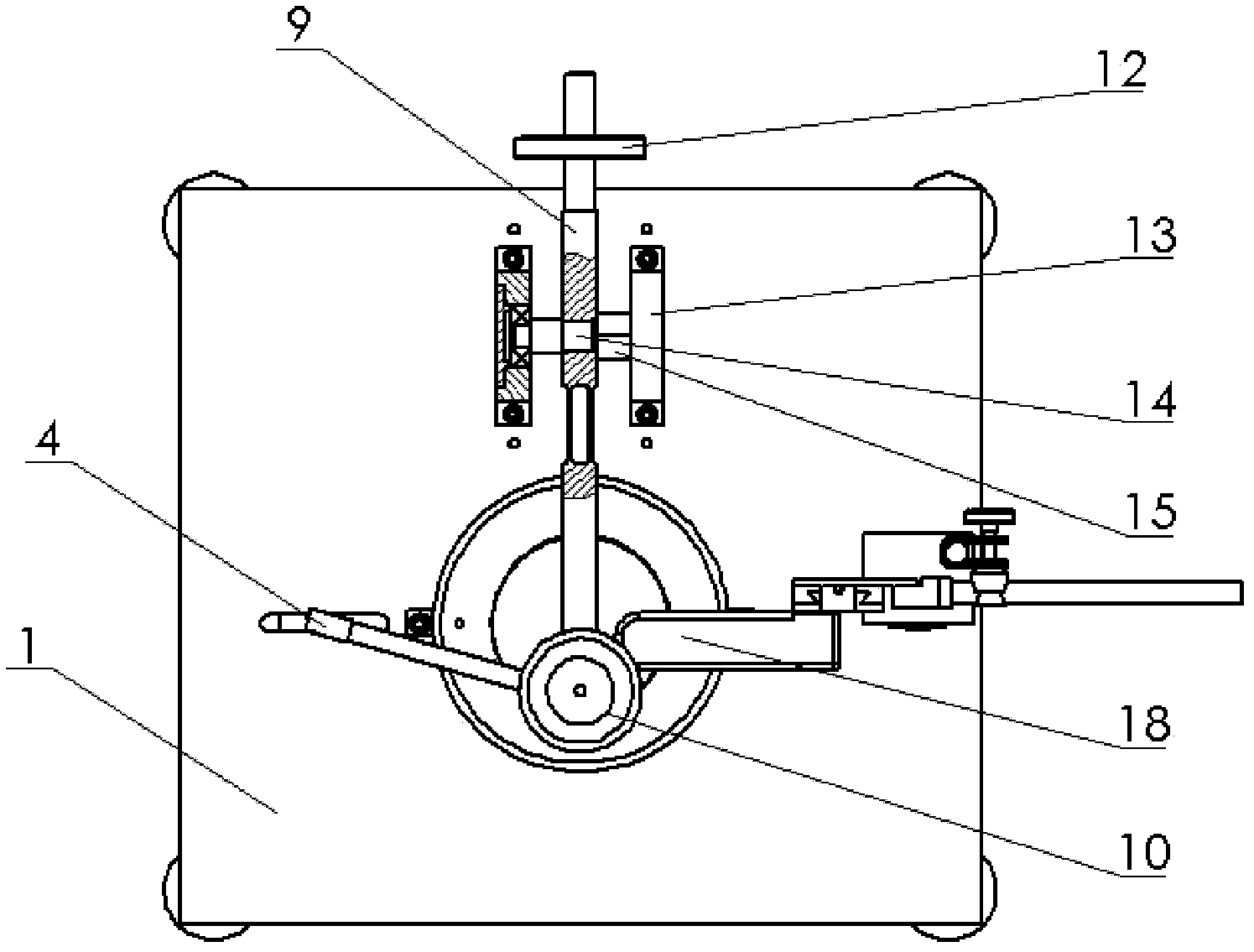

[0029] figure 1 , figure 2 , image 3 As shown, a specific embodiment of a friction and wear testing machine for in-situ measurement of wear in the present invention mainly includes: a test bench 1, a friction and wear measuring device arranged on the test bench 1, and a wear tester arranged on the test bench 1. In-situ measuring device and lubrication device.

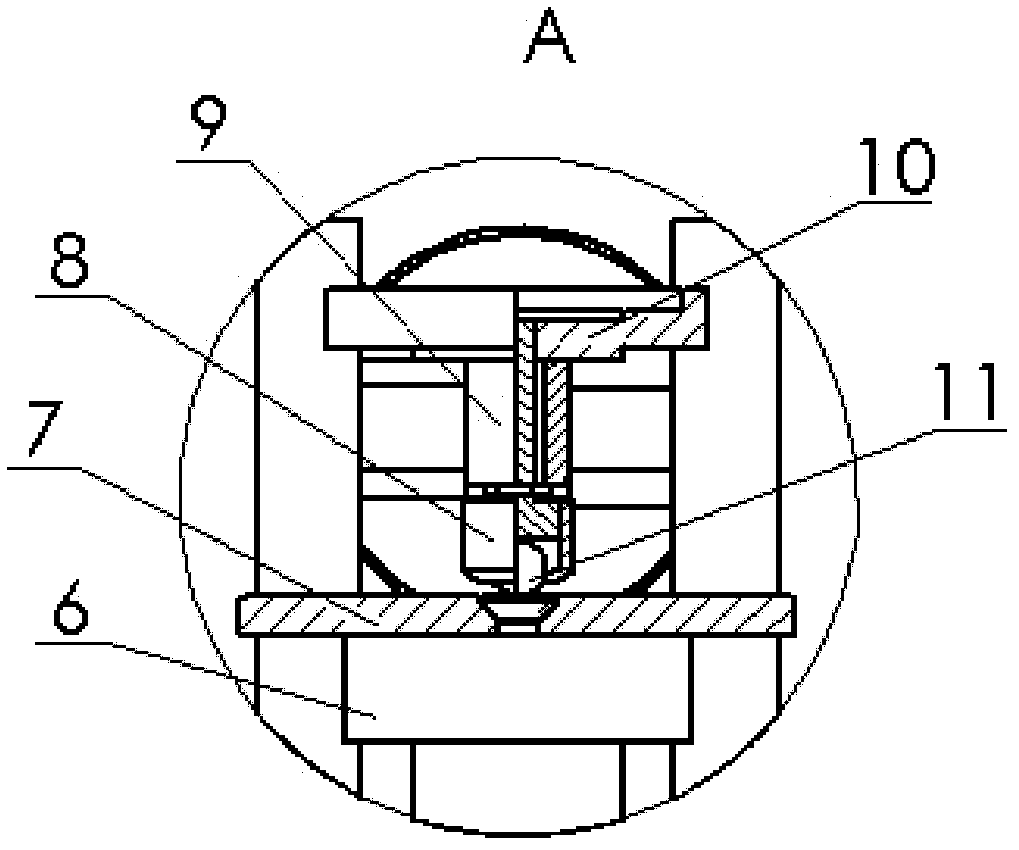

[0030] In the friction and wear measurement device, the rotary table 6 is set on the experimental table 1 and driven by a motor. The lower sample 7 is fixed on the rotary platform 1 by set screws, and rotates together with the rotary platform 6. The strain rod support 13 is fixed on the test bench 1 by four screws. The strain rod 9 is fixed by the fixed nut 15 and the shoulder of the support shaft 14 Fixed on the support shaft 14, the support shaft 14 is supported by the strain rod bracket 13 through bearings, and the upper sample can be a ball, a ring, or a disc. Taking the ball as an example, the ball sample 11 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com