Auxiliary mold-opening mechanism

A technology of positioning mechanism and hot plate, which is applied in the field of auxiliary mold opening mechanism, can solve the problems of increasing production cost and affecting mold opening speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

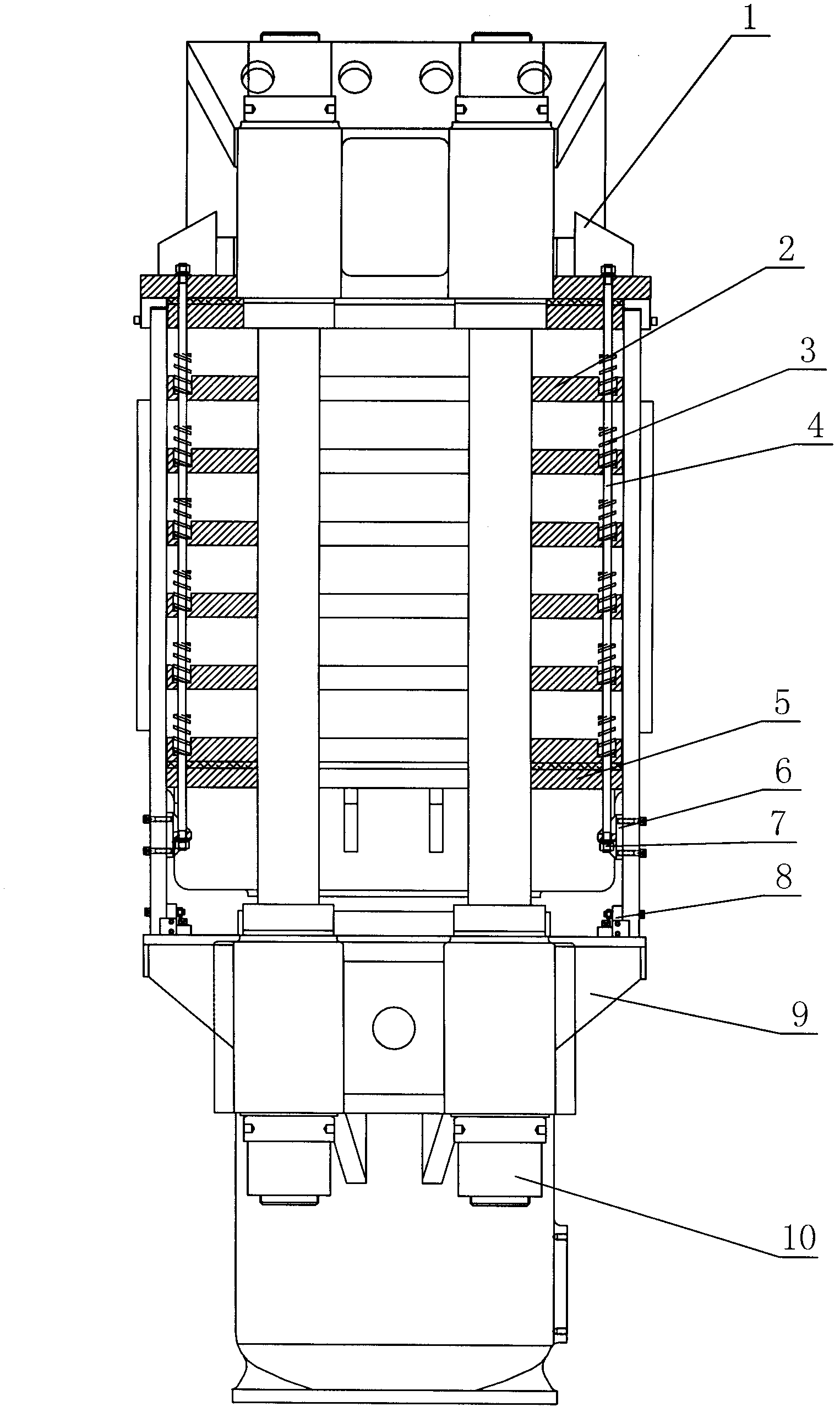

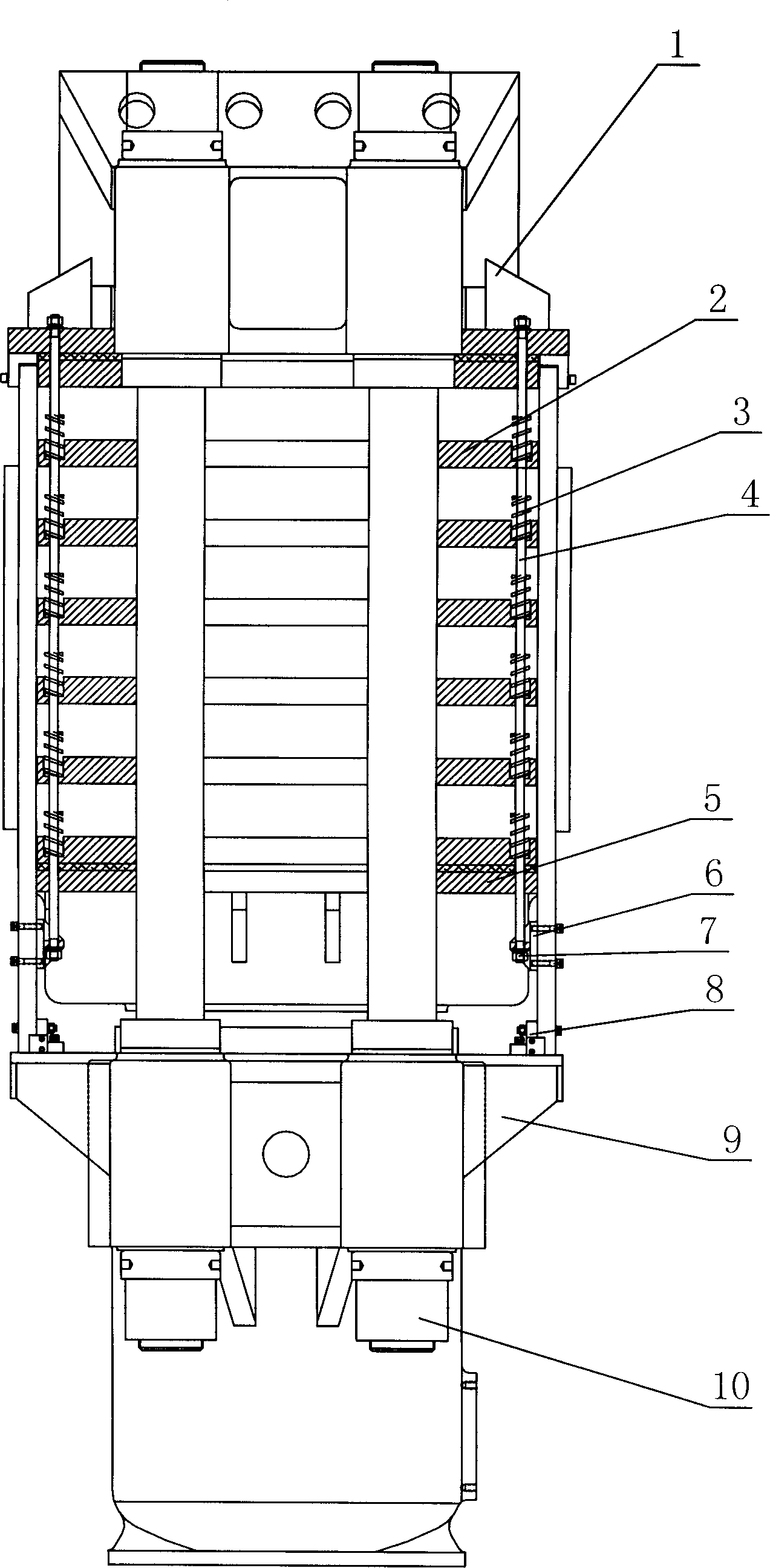

[0013] Please refer to figure 1 as shown, figure 1 It is a sectional view of the auxiliary mold opening mechanism of the present invention. In this embodiment, an auxiliary mold opening mechanism includes an upper top seat 1, an oil cylinder seat 9, a column 10 arranged between them, a middle heating plate 2, and a middle heating plate positioning mechanism 8, and the middle heating plate positioning mechanism 8 The bottom surface is equipped with a positioning support 6, four guide rods 4 are connected between the positioning support 6 and the upper top seat 1, and the corresponding guide rods 4 are provided with through holes at the four corners of the upper top seat 1, and the medium heating plate 2 A counterbore is opened on the four corners of the counterbore, and a spring 3 is placed in the counterbore, and one end of the guide rod 4 passes through the through hole of the upper top seat 1 and is fastened with a washer and a nut, and the medium heating plate 2 passes thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com