High-precision sectional type linear slope compensation circuit

A slope compensation, segmented technology, applied in the direction of electrical components, adjusting electrical variables, instruments, etc., can solve problems such as sub-harmonic oscillation, achieve strong signal anti-interference, and ensure the effect of current feedback capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to describe the present invention more specifically, the technical solutions and related principles of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

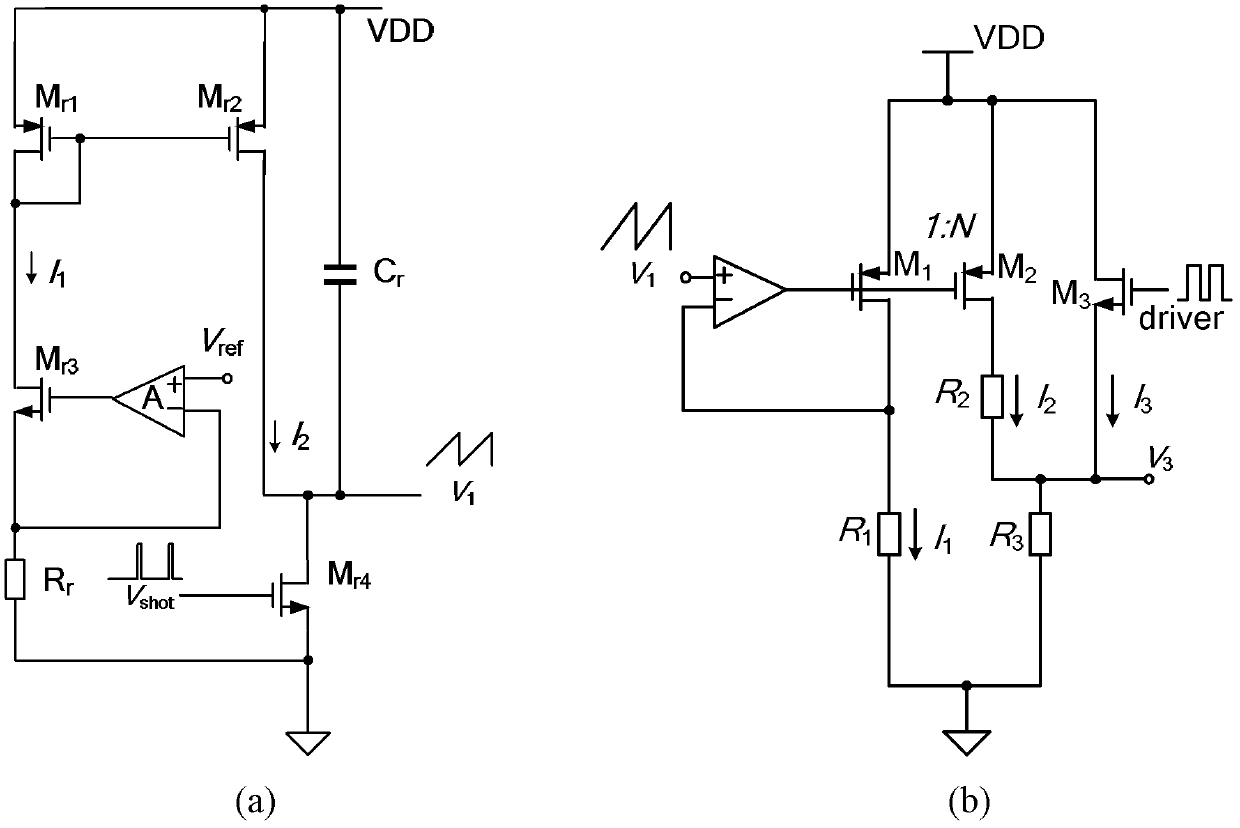

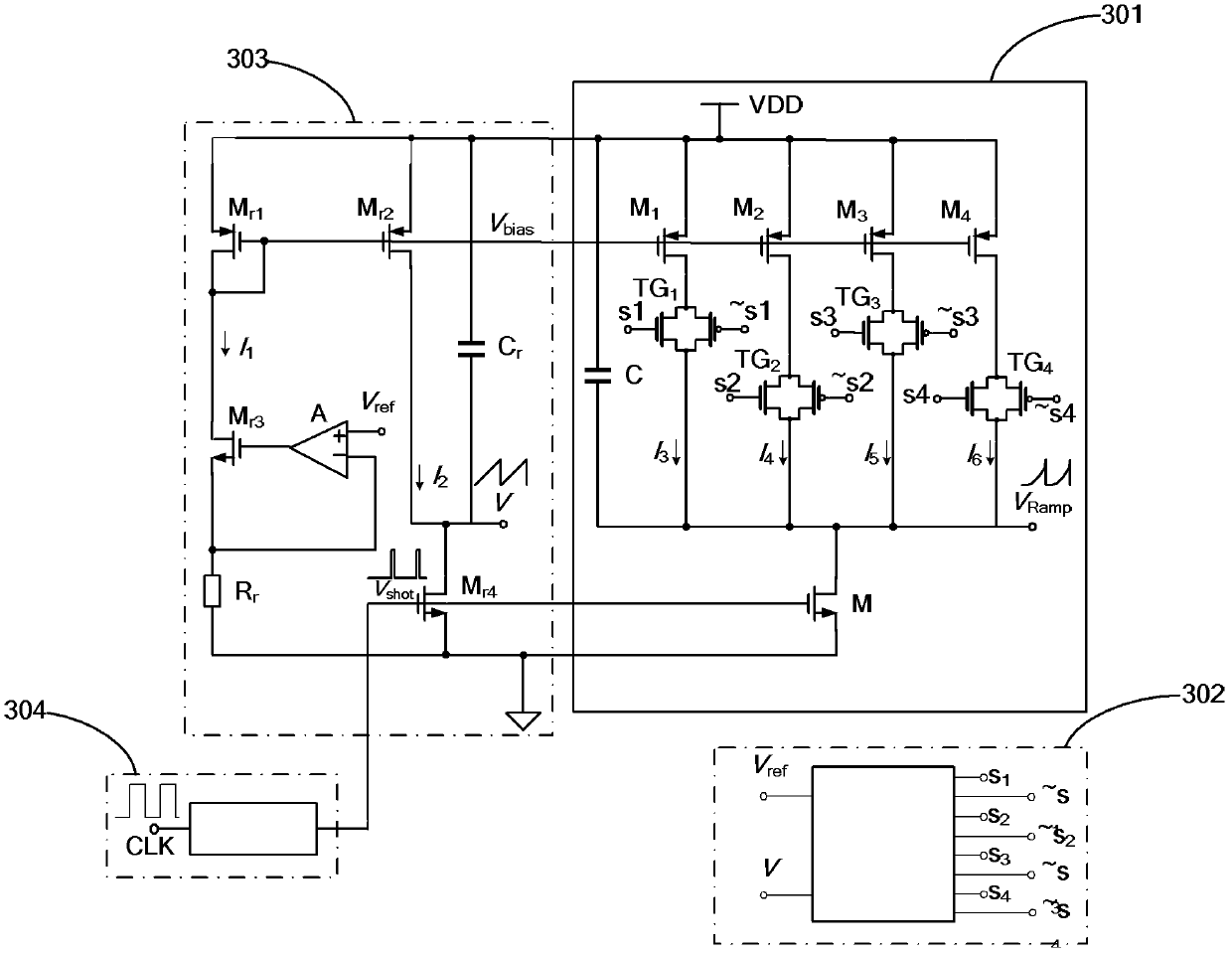

[0032] Such as image 3 As shown, a high-precision segmented linear slope compensation circuit, including for generating slope compensation signal V Ramp The five-segment slope compensation signal generation circuit 301, the five-segment control signal generation circuit 302 that provides control signals for the five-segment slope compensation signal generation circuit 301, and the bias voltage signal for the five-segment slope compensation signal generation circuit 301 V bias The sawtooth wave generation circuit 303 that provides the sawtooth signal V for the five-segment control signal generation circuit 302, and the narrow pulse signal V for the five-segment slope compensation signal generation circuit 301 and the sawtooth wave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com