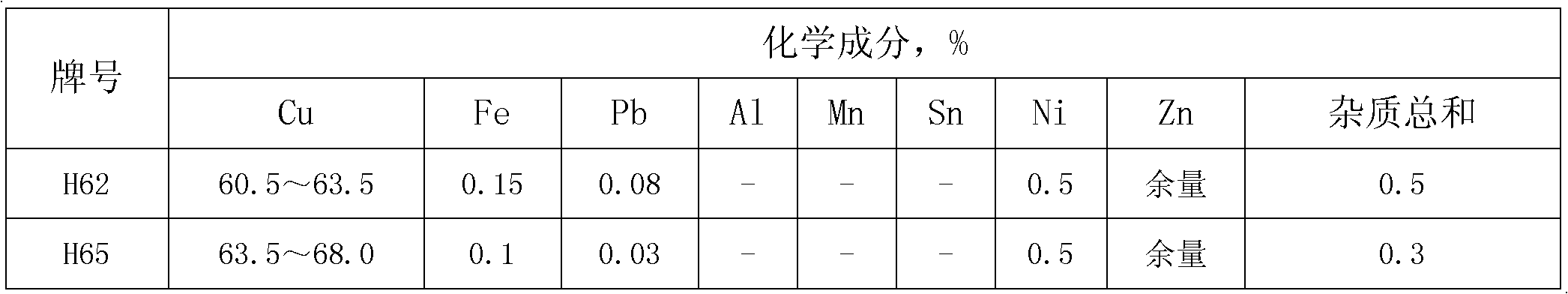

High-tensile property brass band for lamp holder and production process thereof

A tensile property, brass tape technology, applied in the field of high tensile property brass tape for lamp caps and its production process, can solve the problems affecting the quality of finished products, extremely high requirements, high surface quality requirements, etc., to avoid appearance and appearance. Yield, the effect of meeting the requirements of good plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Production process of brass strip H650.25×200M

[0040] 1. Melting and casting process: In this example, the copper cathode is 1: Class B material 2, and the balance is zinc ingots, and the weight percentage of the obtained ingot is:

[0041] Copper: 64.2, lead: 0.0085, iron: 0.0050, tin: 0.0050, nickel: 0.0018, phosphorus: 0.0022, other impurity elements: 0.06, and the balance is zinc.

[0042] The size of the obtained billet is: thickness 165mm, width 210mm, length 4000mm;

[0043] 2. Heating and hot rolling process: the set temperature in the heating and holding zone is 920°C, the actual temperature of the ingot is 820-850°C, and the heating time is 4 hours. Before the ingot is released from the furnace, the temperature of the ingot is uniform; after the ingot is released, it is used for 11 passes hot rolling;

[0044] The resulting strip has a thickness of 13.5 mm and a width of 230 mm;

[0045] 3. Face milling process: Milling the upper and lower surf...

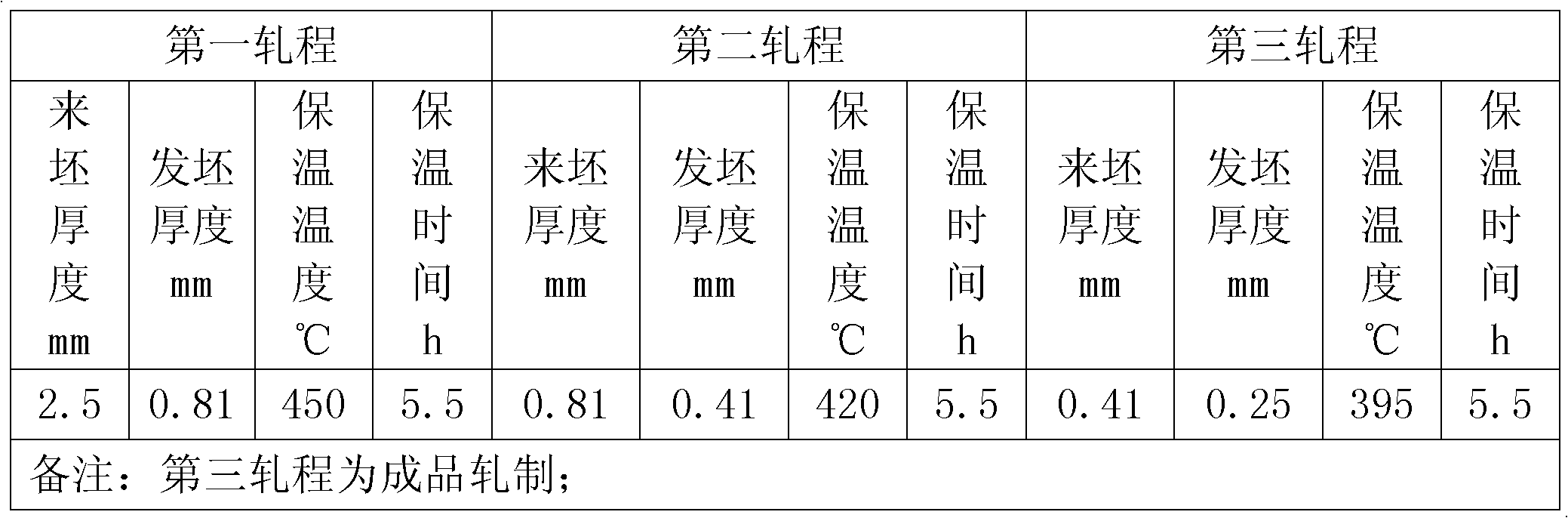

Embodiment 2

[0060] Embodiment 2 (comparative example of embodiment 1): brass strip H650.25 * 200M production process

[0061] 1. Melting and casting process: In this example, the copper cathode is 1: Class B material 4, and the balance is zinc ingots, and the weight percentage of the obtained ingot components is:

[0062] Copper: 64.3, lead: 0.0090, iron: 0.018, tin: 0.025, nickel: 0.020, phosphorus: 0.004, other impurity elements: 0.072, and the balance is zinc.

[0063] The size of the obtained billet is: thickness 165mm, width 210mm, length 4000mm;

[0064] 2. Heating, hot rolling process, face milling process, edge trimming process, blank annealing process, blank pickling process, semi-finished and finished product pickling process, inspection process, edge trimming, and packaging processes are as in Example 1;

[0065] 3. See Table-5 for the rolling and annealing process of semi-finished products and finished products;

[0066] Table-5 Production process of semi-finished products a...

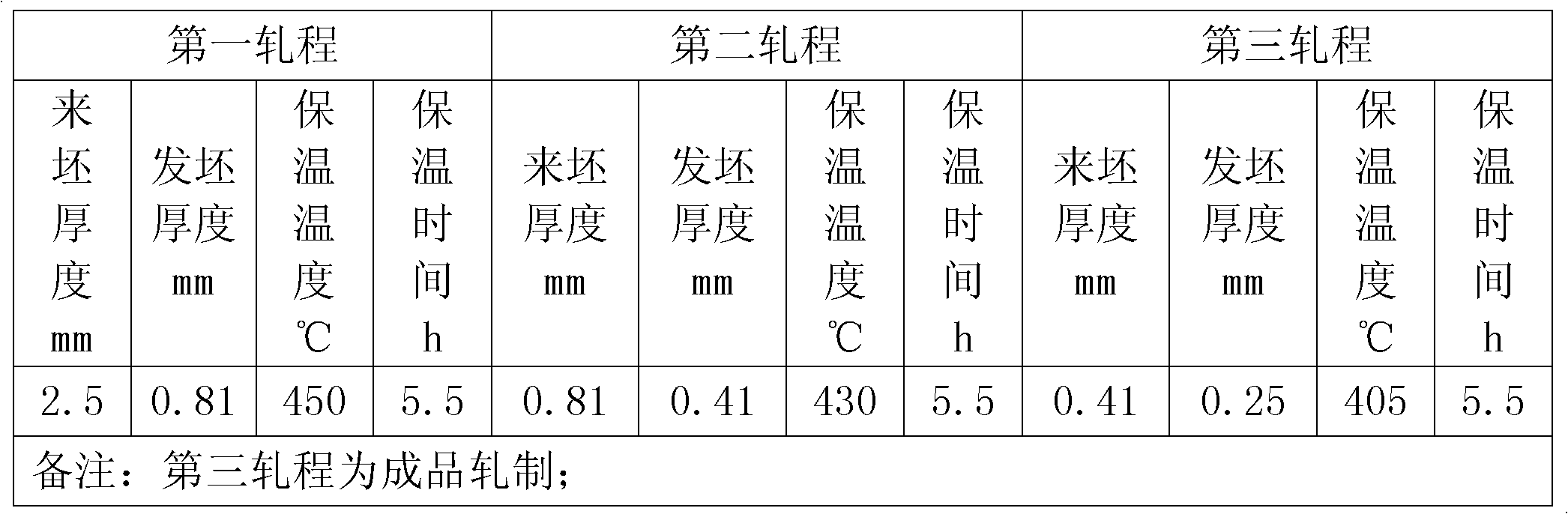

Embodiment 3

[0070] Embodiment 3: Production process of brass strip H650.25×200M

[0071] 1. Melting and casting process: In this example, the copper cathode is 1: Class B material 4, and the balance is zinc ingots, and the weight percentage of the obtained ingot components is:

[0072] Copper: 64.2, lead: 0.0075, iron: 0.012, tin: 0.018, nickel: 0.015, phosphorus: 0.0023, cerium: 0.002: 0.0055, other impurity elements: 0.062, and the balance is zinc.

[0073] The size of the obtained billet is: thickness 165mm, width 210mm, length 4000mm;

[0074] 2. Heating, hot rolling process, face milling process, edge trimming process, blank annealing process, blank pickling process, semi-finished and finished product pickling process, inspection process, edge trimming, and packaging processes are as in Example 1;

[0075] 3. See Table-6 for the rolling and annealing process of semi-finished products and finished products;

[0076] Table-6 Production process of semi-finished products and finished p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com