Mounting process for lamp strips of passenger rooms of railway vehicles

A railway vehicle and installation process technology, which is applied to railway vehicle lighting devices, railway car body parts, lighting devices, etc., can solve the problems that the light strip structure cannot meet the requirements and the speakers cannot be directly installed, and achieves high assembly process efficiency and assembly. high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

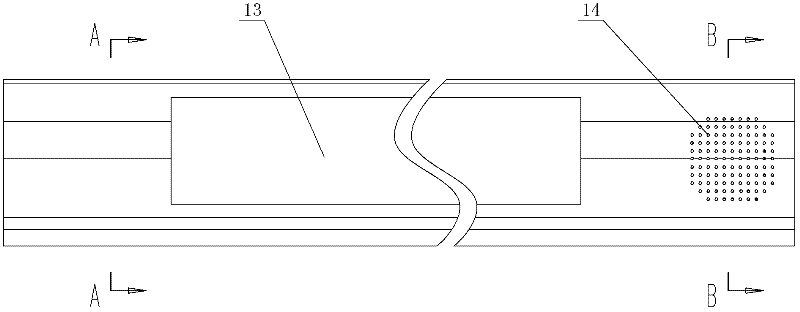

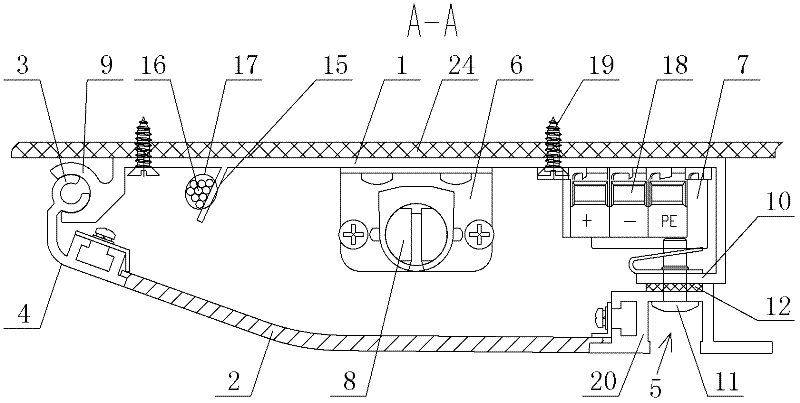

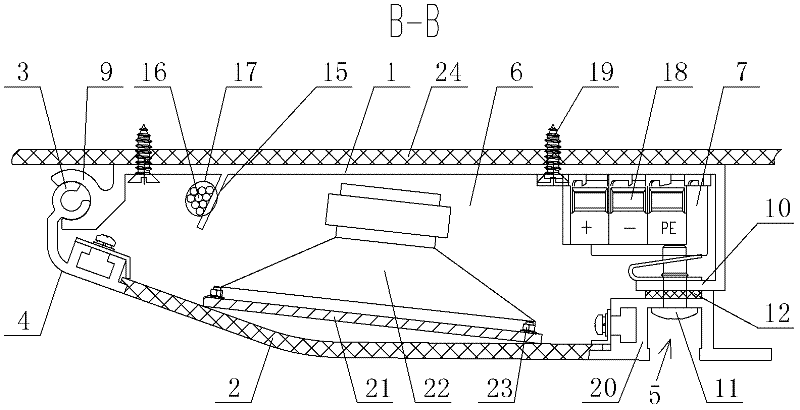

[0018] like figure 1 , figure 2 , image 3 As shown, it is the light strip for the passenger compartment of the railway vehicle to be installed in this embodiment.

[0019] The installation process of the light strip in the passenger compartment of the railway vehicle includes the following steps:

[0020] Step 1: Fix the T5 lamp holder 6, T5 electronic ballast 7 and WAGO terminal block 18 on the lower side of the top plate 1 of the light strip, and fix the cable 16 on the side of the cable fixing plate 15 with the cable tie 17, and perform wiring connect;

[0021] The second step is to fix the light strip top plate 1 and the interior roof plate 24 through wood screws 19, and install the T5 lamp 8 into the T5 lamp holder 6;

[0022] The third step is to install the connecting part 20 and the rotating part 4 on the inner and outer sides of the lampshade 2 respectively;

[0023] Step 4: Fix the speaker mounting plate 21 above the lampshade 2, and install the speaker 22;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com