Method for determining deep rock structural surface attitude by utilizing television image of single vertical drilling hole

A TV image and structural surface technology, applied in optical exploration and other directions, can solve the problems of high cost of deep drilling, unsuitable fractured structural surface, and high cost of three drilling holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

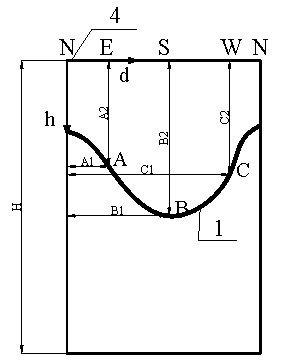

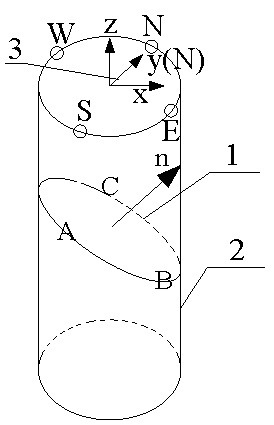

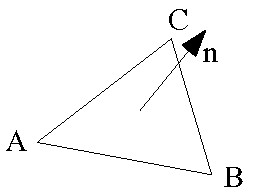

[0042] According to the actual situation of on-site drilling; the drilling depth is 12m, and the hole diameter is 130mm. The drilling TV image is processed (such as Figure 5 shown), read the position coordinates (unit: m) of three points that are not collinear in the structural surface in the image: A 1 (0, -4.25), B 1 (0.21, -4.35), C 1 (0.3266,-4.3); Carry out coordinate transformation and substitute formula (1) to get the space Cartesian coordinates: A 1 (0, 0.065, -4.25), B 1 (-0.0058, -0.0647, -4.35), C 1 (-0.0619, 0.02, -4.3); Substituting the normal vector formula (2) to obtain the normal vector of the structural surface is n (0.001985, 0.00648, -0.0083); substituting the human formula (3) to calculate the inclination angle to be 39.3°; intercept the plane N(n 1 , n 2 ) is: N(-19.85, -64.8), located in the third quadrant; the inclination obtained by substituting formula (4) is 197°; then the occurrence of the structural plane is determined to be 197°∠39.3°.

example 2

[0044] According to the actual situation of drilling on site, extract the vertical drilling depth of 12m, the hole diameter is 130mm drilling TV image for processing (such as Image 6shown), read the position coordinates (unit: m) of three points in the image that are not collinear on the structural surface: A 2 (0, -10.7), B 2 (0.16, -10.55), C 2 (0.3266,-10.65); Carry out coordinate conversion and substitute formula (1) to get the space Cartesian coordinates: A 2 (0, 0.065, -10.7), B 2 (0.0408, -0.0505, -10.55), C 2 (-0.0619, 0.02, -10.65); the formula (2) for the normal vector of the structural surface is: n(0.000975, -0.011325, -0.008985); the inclination angle obtained by the formula (3) is 51.68°; Obtain N(n by intercepting the plane projection 1 , n 2 ) is: N(-9.75, 113.25), located in the fourth quadrant; the inclination obtained by substituting formula (4) is 315°; then the occurrence of the two structural planes is determined to be 315°∠51.68°.

[0045] The st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com