Model deflection sedimentation control device for geotechnical centrifuge test

A geotechnical centrifuge and settlement control technology, applied in measuring devices, using stable tension/pressure testing materials strength, instruments, etc., can solve the problem of not being able to accurately grasp the impact of uneven settlement of embankment filling and uneven deformation of roadbed surface It can solve the problems of law, uneven deformation of model embankment filling, uneven settlement of subgrade surface, etc., to achieve the effect of compact structure, small space occupation and high reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

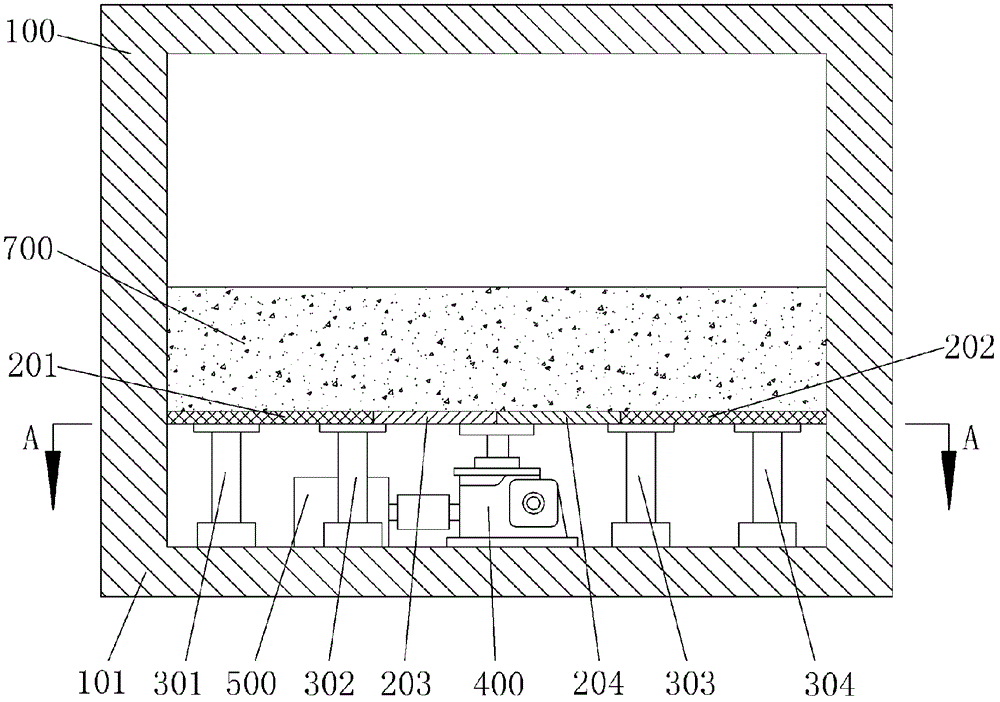

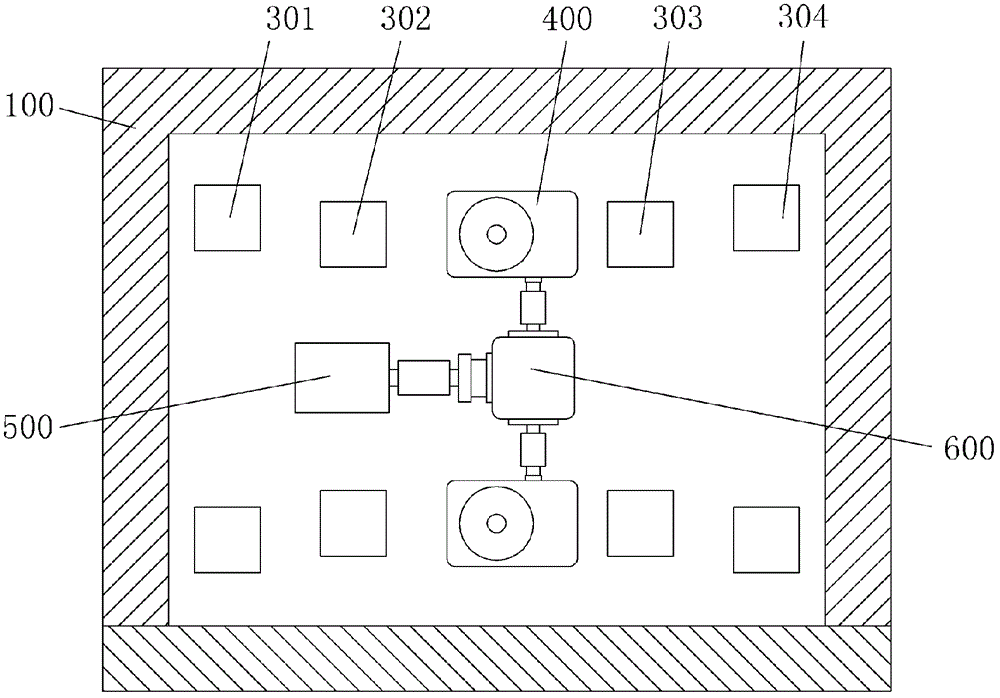

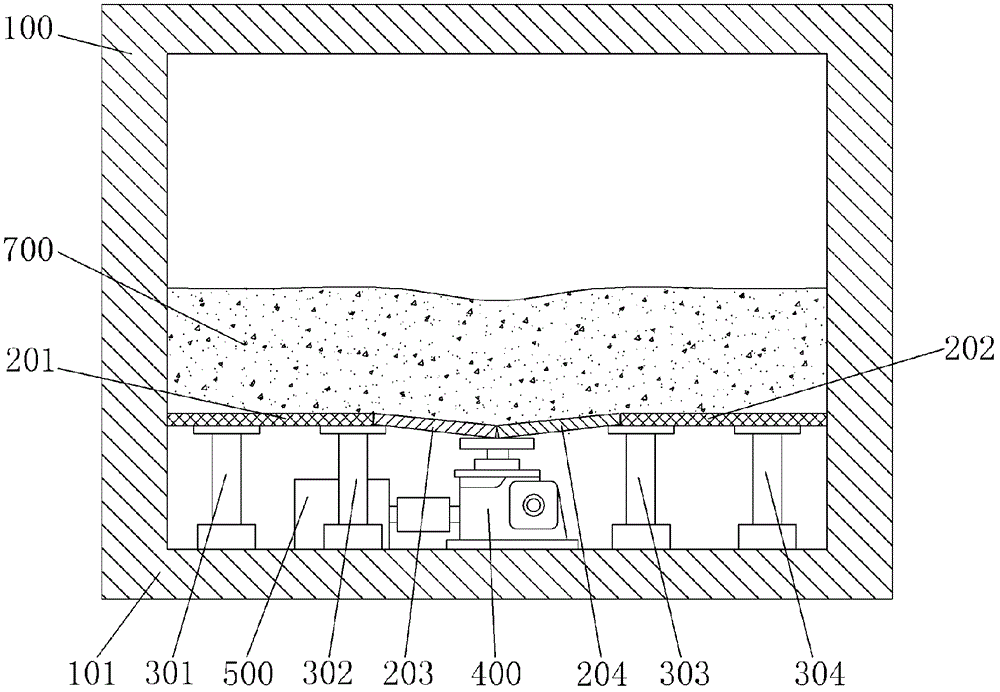

[0023] Figure 1~3 Shown, a kind of embodiment of the present invention is, a kind of model deflection type settlement control device of geotechnical centrifuge test, and it is composed of:

[0024] The left side of the bottom 101 of the model box 100 is fixed with two rows of left support piers 301,302, and the two rows of left support piers 301,302 are supported with a left fixed plate 201; the right side of the bottom of the box 101 is fixed with two rows of right support piers 303, 304, the two rows of right support piers 303, 304 are supported with a right fixed plate 202;

[0025] A row of elevators 400 is fixed in the middle of the bottom of the box 101. The right end of the left inclined plate 203 is lapped on the flange of the elevator 400, and the left end is lapped on the left support pier 302 adjacent to the elevator 400; Connected to the flange of the elevator 400, the right end is lapped on the right supporting pier 303 adjacent to the elevator 400;

[0026] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com