Tractor

A tractor and gear technology, applied in the field of tractors, can solve the problems of high manufacturing cost, high manufacturing difficulty, and high raw material cost, and achieve the effect of easy manufacturing, simple structure, and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

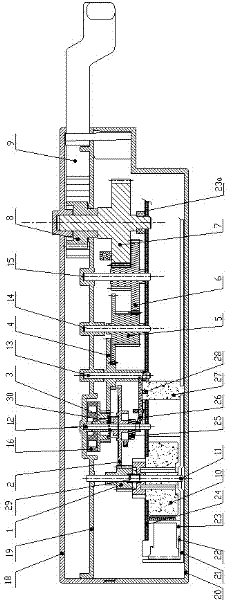

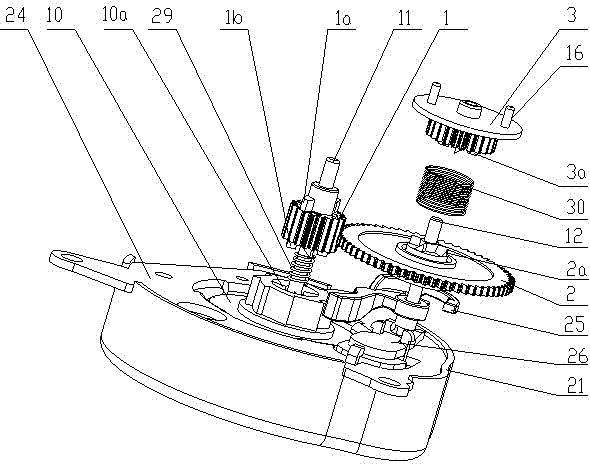

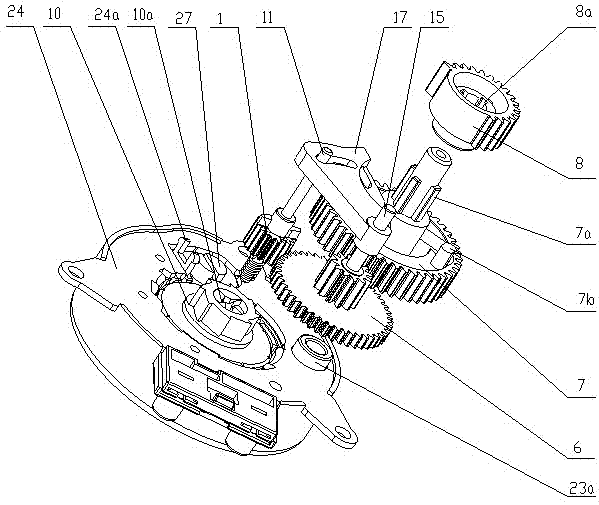

[0033] Such as figure 2As shown, the present invention separates the rotor magnetic steel 10 of the synchronous motor from the central gear 1, and sets a cross-toothed structure separated up and down. After meshing, the central gear 1 drives the set reduction gear assembly. Between the 3, a cross-toothed structure is similarly arranged. Properly increase the height of the tooth part of the central gear, so that the tooth part of the central gear 1 is always meshed with the tooth part of the gear 2, so that the two separation and meshing structures can be connected in series, which plays a key role in traction start, traction maintenance and traction recovery. Easy controls. Such as Figure 9 As shown, due to the simple control device designed above, the rest of the reduction gear assembly uses ordinary gears 4 and 5 to replace the original complex reduction assembly mainly composed of planetary gears, making the tractor structure simpler and more reasonable .

[0034] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com