Composite multi-crank rocker mechanism for roll crusher

A technology of roller crusher and rocker mechanism, which is applied in the direction of grain processing, etc., which can solve the problems of huge equipment, affecting crushing efficiency, lack of shearing and crushing mechanism, etc., and achieve a reasonable distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

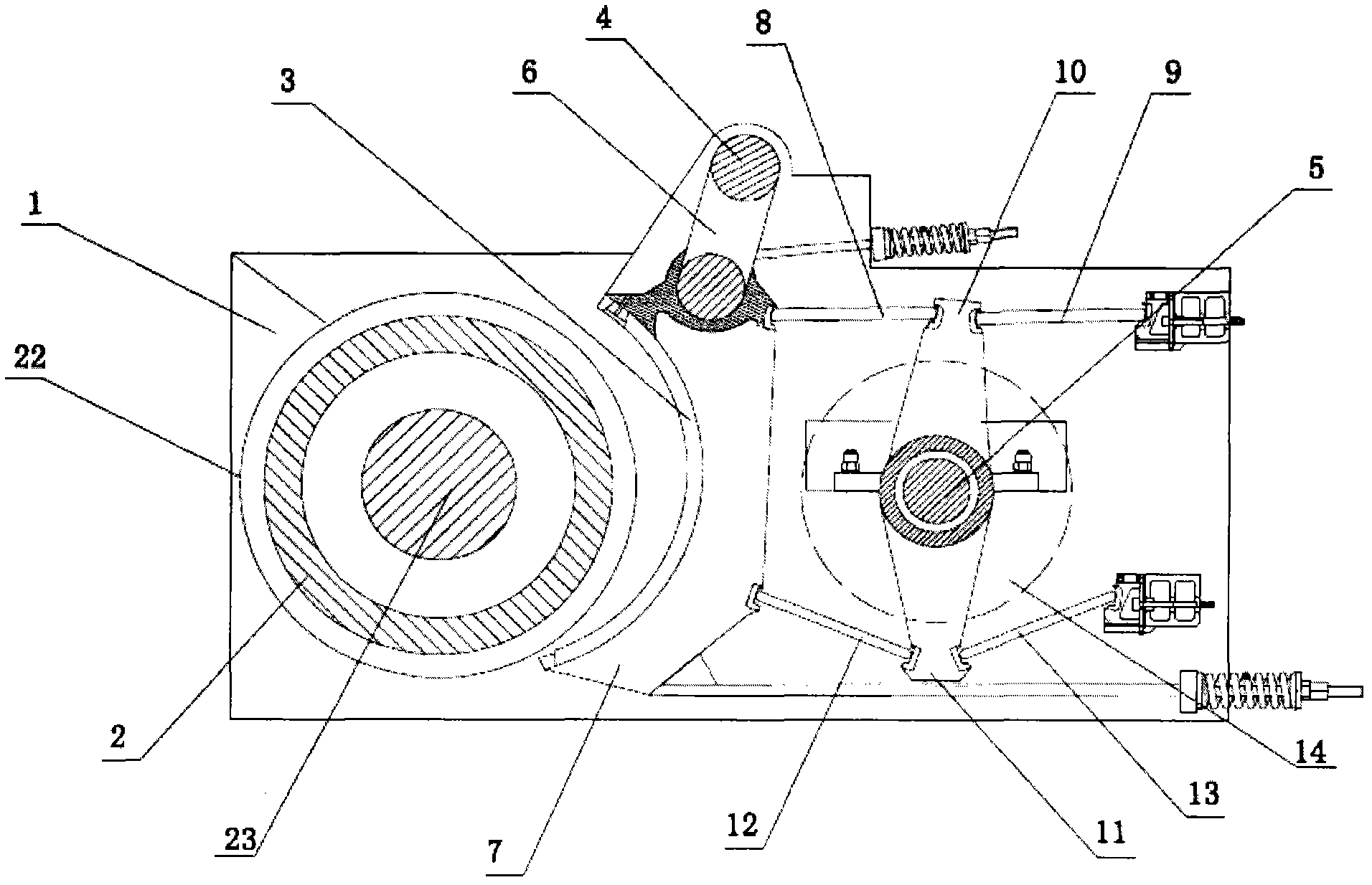

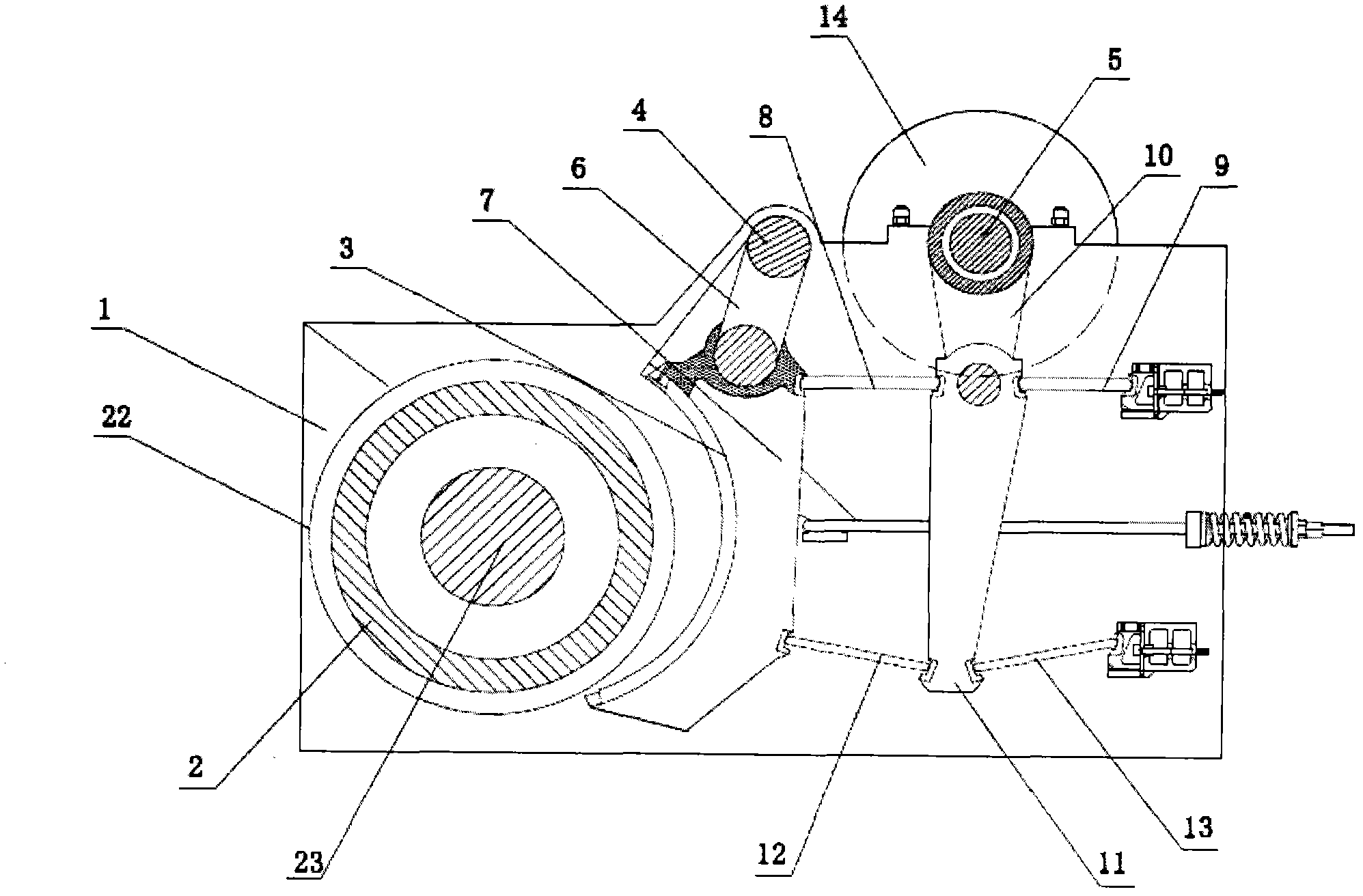

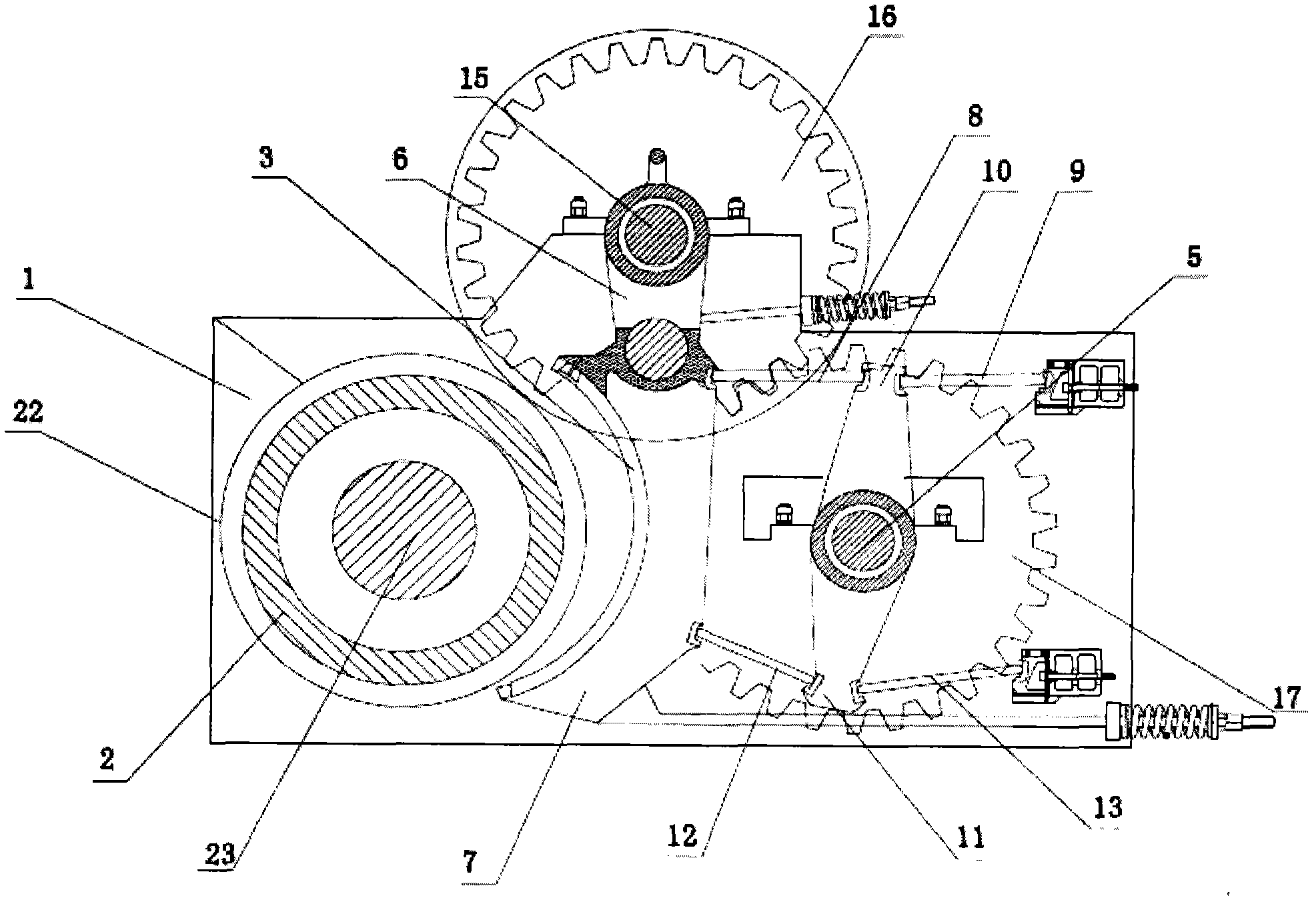

[0060] Embodiment 1: as figure 1 As shown, a composite multi-crank rocker mechanism for a roller crusher includes a frame 1 on which a pair of crushing pairs are arranged, and the pair of crushing pairs includes a crushing roller 2 and a crushing wall 3 . The crushing roller 2 is arranged on the roller shaft 23 , and the roller shaft 23 is arranged on the frame 1 and connected with the transmission wheel 22 .

[0061] The connection plate 6 is pivotally connected to the front concentric support shaft 4, the front concentric support shaft 4 (the front concentric support shaft 4 is what we call a straight shaft) is pivotally connected to the frame 1, the lower end of the connection plate 6 is connected to the upper end of the front movable jaw 7 The crushing wall 3 is arranged on the front movable jaw 7; the right side of the crushing roller 2 confronts the crushing wall 3 to form a crushing chamber.

[0062] The lower end of the upper rear movable jaw 10 and the upper end of t...

Embodiment 2

[0065] Embodiment 2: The front end of the upper front toggle plate 8 is pivotally connected to the bottom of the rear side of the connecting plate 6; the rest are the same as in Embodiment 1.

Embodiment 3

[0066] Embodiment 3: The front end of the upper front toggle plate 8 is pivotally connected to the pivot shaft of the connecting plate 6 and the front movable jaw 7; the rest is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com