Tension-pressure conversion aid for calibration of tensile machine

An auxiliary tool and pressure conversion technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., to achieve the effect of broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

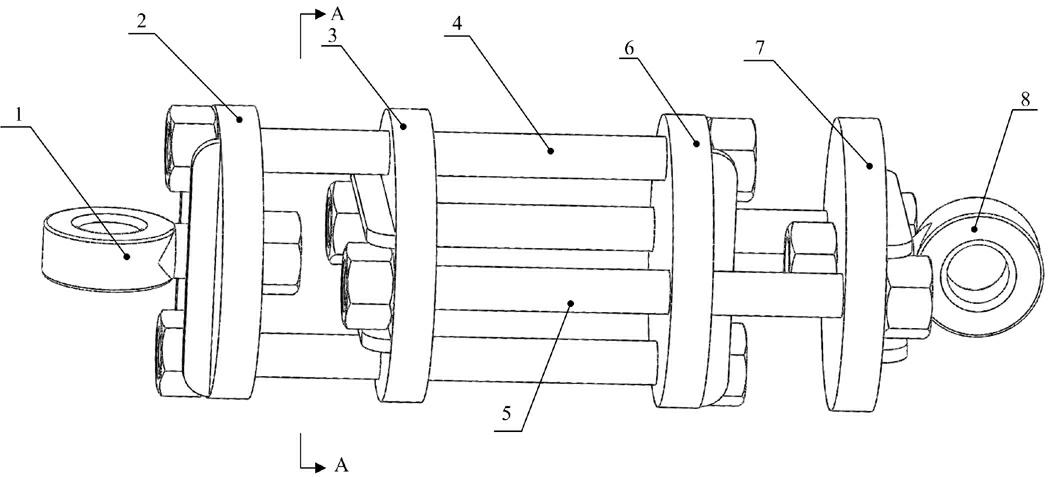

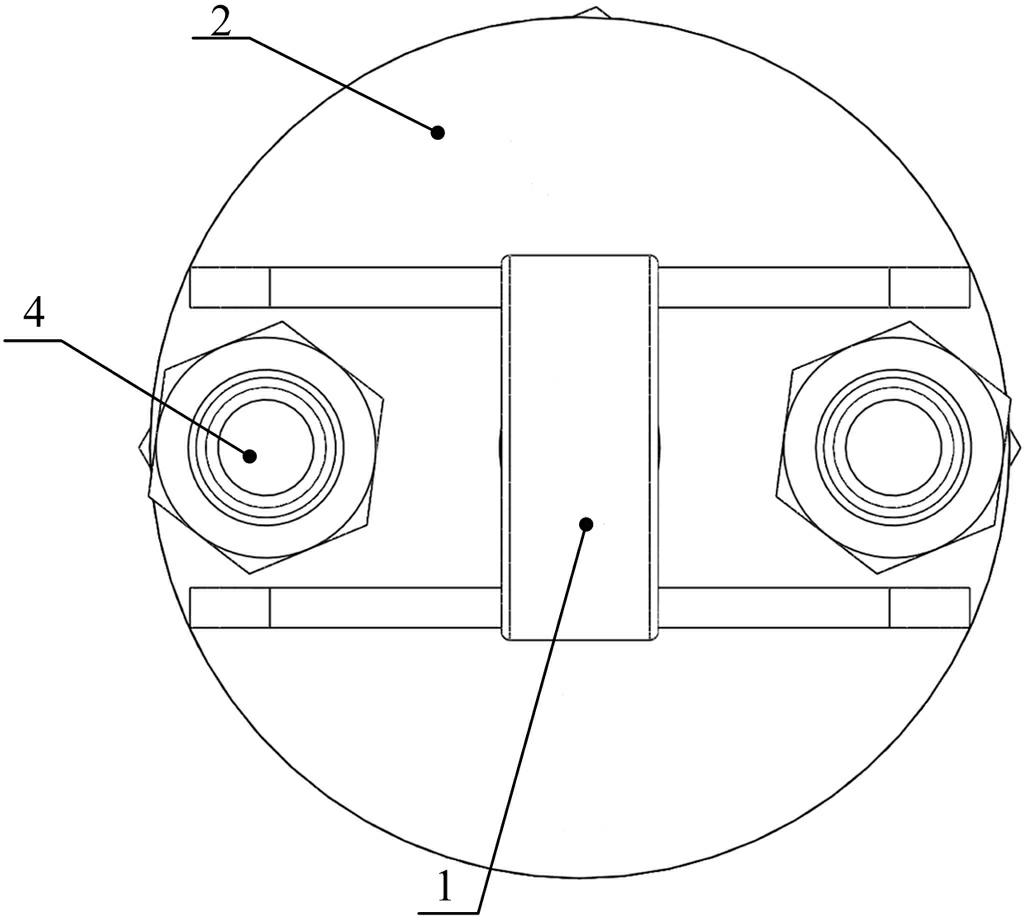

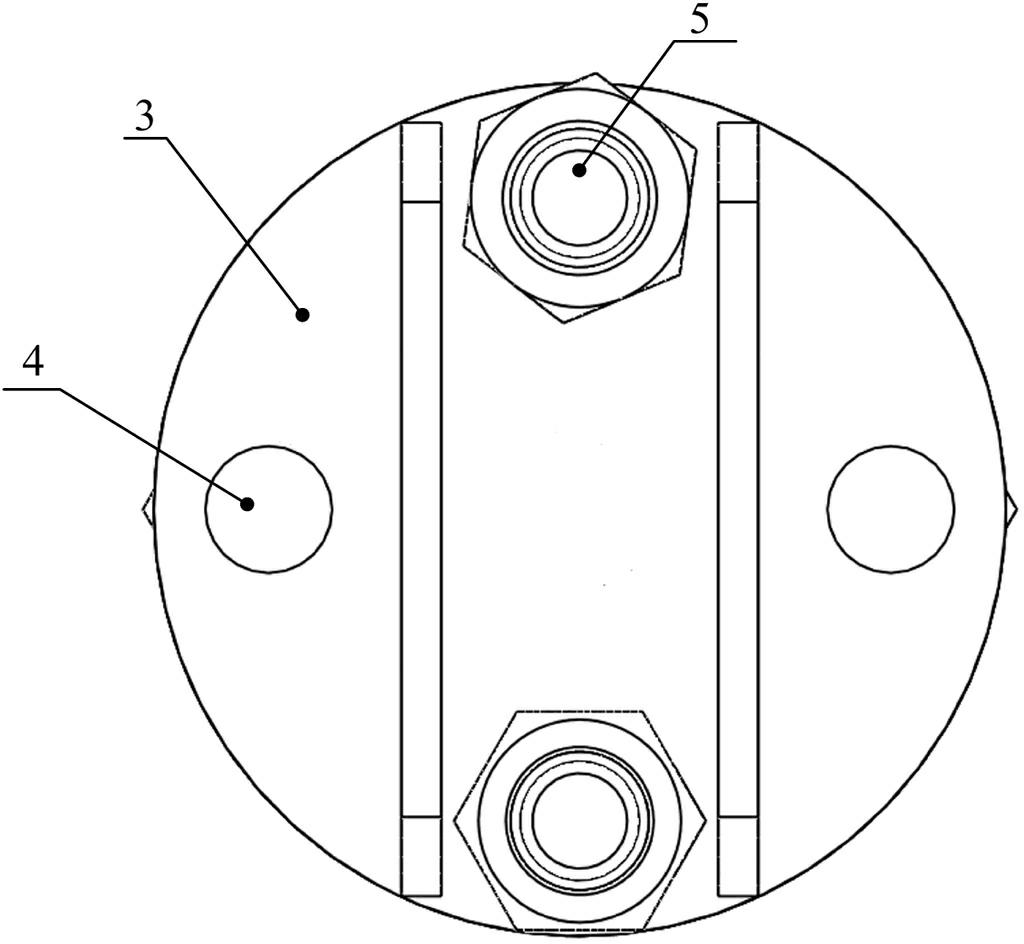

[0016] see figure 1 , the tension-compression conversion auxiliary tool for the calibration of the tensile machine includes a left pull plate 3, a right pull plate 6, two left pull rods 4 and two right pull rods 5; Four tie rod holes are evenly distributed on the plate 3 and the right pull plate 6 respectively; the two ends of the two left tie rods 4 and the two ends of the two right tie rods 5 are screw rods. Two left pull rods 4 pass through the two pull rod holes on the left pull plate 3 and the right pull plate 6, one end of which is fixedly connected to the right pull plate 6 through nuts, and the other end is fixedly connected to the left three-hole pull plate through nuts 2. The middle part of the outer surface of the left three-hole pull plate 2 is fixedly connected to the left pull ring 1 through nuts; two right pull rods 5 pass through the other two pull rod holes on the right pull plate 6 and the left pull plate 3, and one end The left pull plate 3 is fixedly conne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap