Pile-forming construction equipment for ramming and compacting filler of composite foundation pile

A technology of composite foundation and filling material, which is applied in basic structure engineering, sheet pile wall, building and other directions, can solve the problems of limited, different, and difficult to expand the scope of the lifting capacity of the hoisting mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

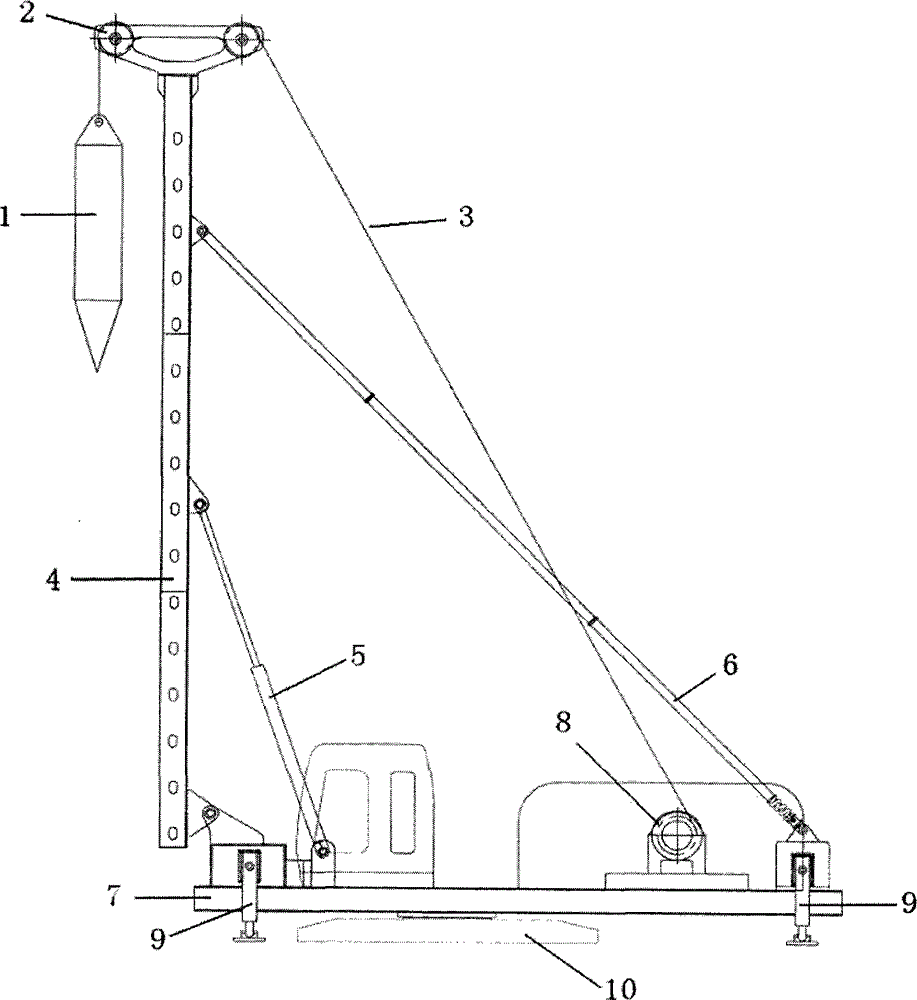

[0022] As an embodiment of the present invention, the pile-forming construction equipment for tamping, expanding and compacting the filling material of composite foundation piles includes a rotary platform 7, on which a mast 4 is arranged; 7 is provided with a traveling mechanism 10; a winch mechanism, the winch mechanism includes a winch 8 and a wire rope 3, one end of the wire rope 3 is wound on the winch 8 and driven, and the other end of the wire rope 3 is arranged on the top of the above-mentioned mast 4 The pulley 2, the steel wire rope 3 hangs downward through the pulley 2, and the heavy hammer 1 is used for impacting, expanding and compacting the filling material of the composite foundation pile. The heavy hammer 1 consists of a roughly columnar hammer body and a roughly hammer-tip hammer. Bottom structure, the above-mentioned hoist 8 adopts a hydraulic hoist, and the hydraulic hoist can be used in different soil constructions, and a different weight 1 corresponding to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com