Turning driving front axle of cross country vehicle

A technology for off-road vehicles and front axles, applied to axles, wheels, vehicle parts, etc., can solve the problems of small axles and bridges, and achieve reliable performance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

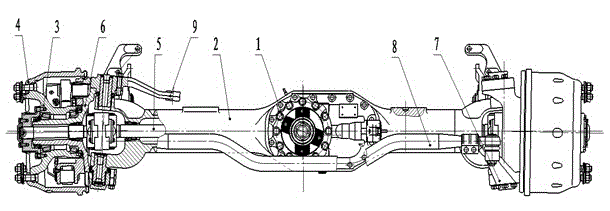

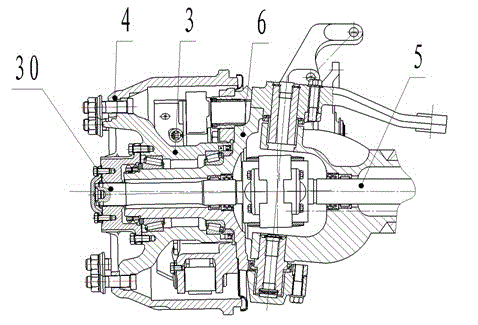

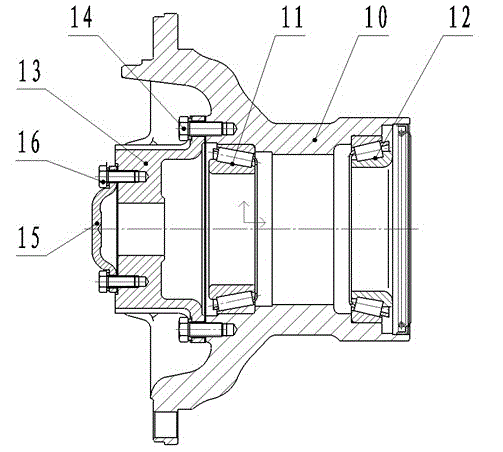

[0019] Embodiment one: see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 The shown steering drive front axle of a kind of off-road vehicle includes a front axle housing 2, a front final drive 1 arranged in the middle of the front axle housing, two front axle shafts 5 respectively connected to the front final drive at one end, respectively Two steering knuckles 6 that are connected to the two ends of the front axle housing and are connected with the other ends of the two front axle shafts 5, and two wheel input shafts 30 that are respectively connected with the two steering knuckles; the innovation points are: the front main The speed reducer 1 is a single-stage deceleration mechanism with a speed ratio of 1.208; the two front wheel drive shafts 30 are connected with a front wheel drive 3 respectively, and a front brake 4 is respectively arranged on the two front wheel drive 3; The front wheel driver consists of the front wheel hub 10, the first bearing group 11...

Embodiment 2

[0020] Embodiment two: see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 The shown steering drive front axle of a kind of off-road vehicle includes a front axle housing 2, a front final drive 1 arranged in the middle of the front axle housing, two front axle shafts 5 respectively connected to the front final drive at one end, respectively Two steering knuckles 6 that are connected to the two ends of the front axle housing and are connected with the other ends of the two front axle shafts 5, and two wheel input shafts 30 that are respectively connected with the two steering knuckles; the innovation points are: the front main The speed reducer 1 is a single-stage reduction mechanism with a speed ratio of 2.727; the two front wheel drive shafts 30 are fitted with a front wheel drive 3 respectively, and the two front wheel drive 3 are respectively provided with a front brake 4; The front wheel driver consists of the front wheel hub 10, the first bearing group 11 an...

Embodiment 3

[0021] Embodiment three: see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 The shown steering drive front axle of a kind of off-road vehicle includes a front axle housing 2, a front final drive 1 arranged in the middle of the front axle housing, two front axle shafts 5 respectively connected to the front final drive at one end, respectively Two steering knuckles 6 that are connected to the two ends of the front axle housing and are connected with the other ends of the two front axle shafts 5, and two wheel input shafts 30 that are respectively connected with the two steering knuckles; the innovation points are: the front main The speed reducer 1 is a single-stage reduction mechanism with a speed ratio of 2.135; the two front wheel drive shafts 30 are connected with a front wheel drive 3 respectively, and a front brake 4 is respectively arranged on the two front wheel drive 3; The front wheel driver consists of the front wheel hub 10, the first bearing group 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com