A flat slider

A flat, horizontal groove technology, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of lowering the scraping hand, stuck lines, etc., to reduce the inconvenience of jamming the trousers line, easy to assemble, and eliminate scraping. effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

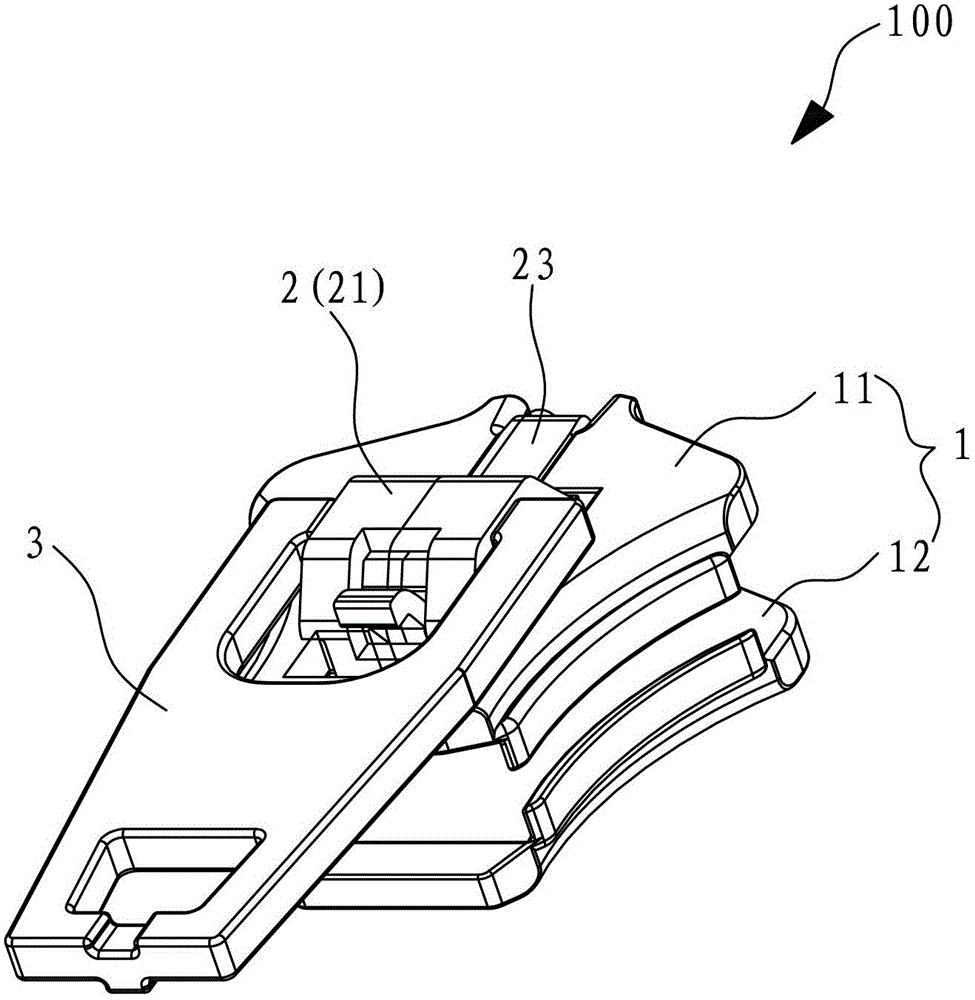

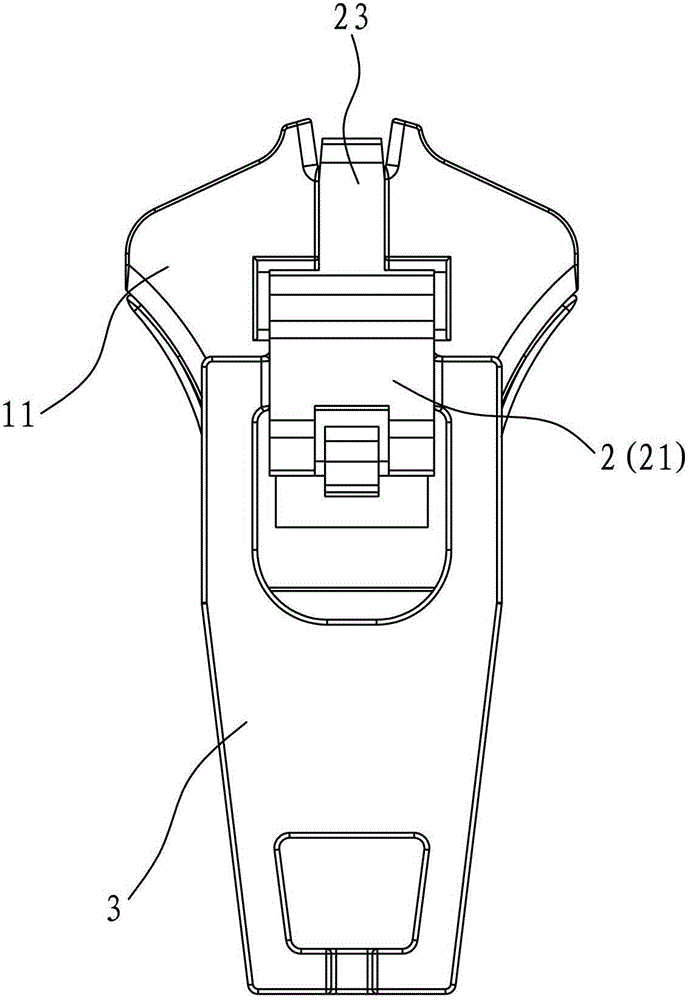

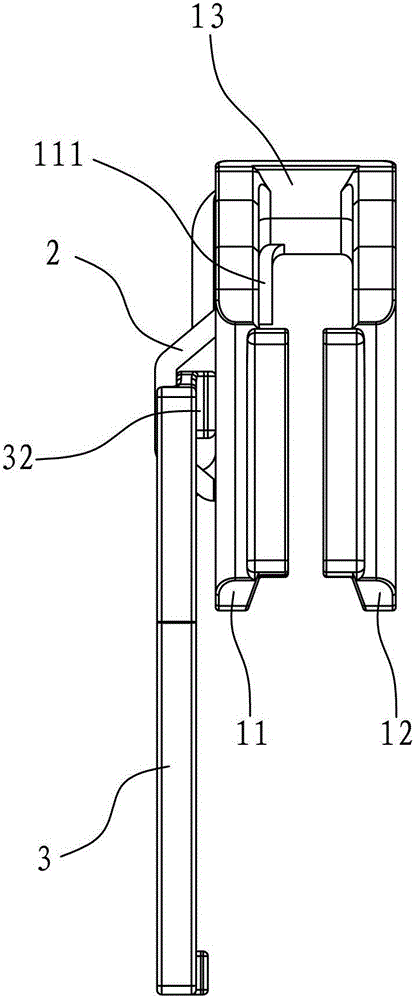

[0035] Such as Figure 1 to Figure 5 As shown, the present invention relates to a flat slider 100, which includes a slider body 1, an elastic piece 2 and a pull piece 3, wherein:

[0036] The slider body 1 has an upper wing 11, a lower wing 12 and a guide post 13 connecting the upper wing 11 and the lower wing 12, the upper wing 11 is formed with an engaging lug 14 and a perforation 15, the perforation 15 Through the two surfaces of the upper fin 11 , a T-shaped sinker 16 is formed on the upper fin 11 , including a horizontal groove 161 and a vertical groove 162 .

[0037] The elastic piece 2 has a central base 21, a locking claw 22 and a front end portion 23. There is an opening 24, the locking pawl 22 passes through the perforation 15 of the upper flap 11 to lock the zipper, the edge of the opening 24 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com