Self-locking slider

A self-locking and locking groove technology, applied in the field of zippers, can solve problems such as bad, stuck lines, and positioning of scraping handles, etc., to reduce the inconvenience of stuck trouser lines, increase elasticity and locking strength, and improve elasticity and locking The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

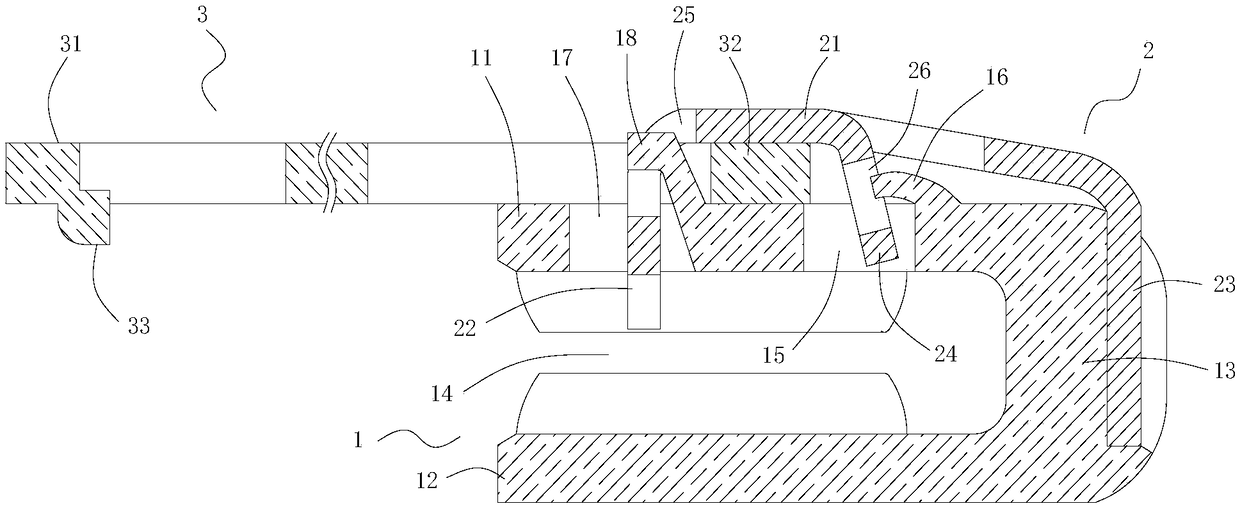

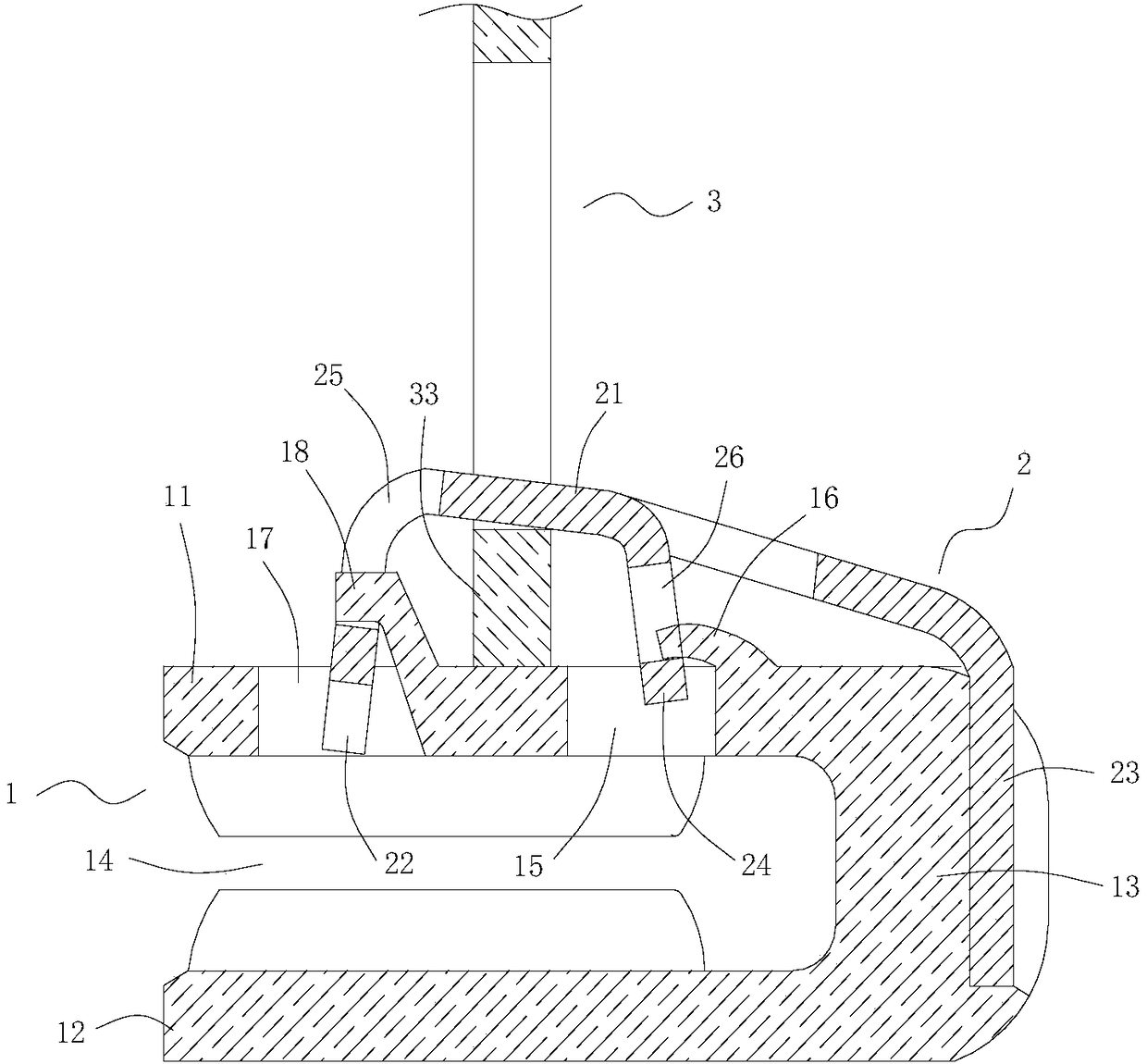

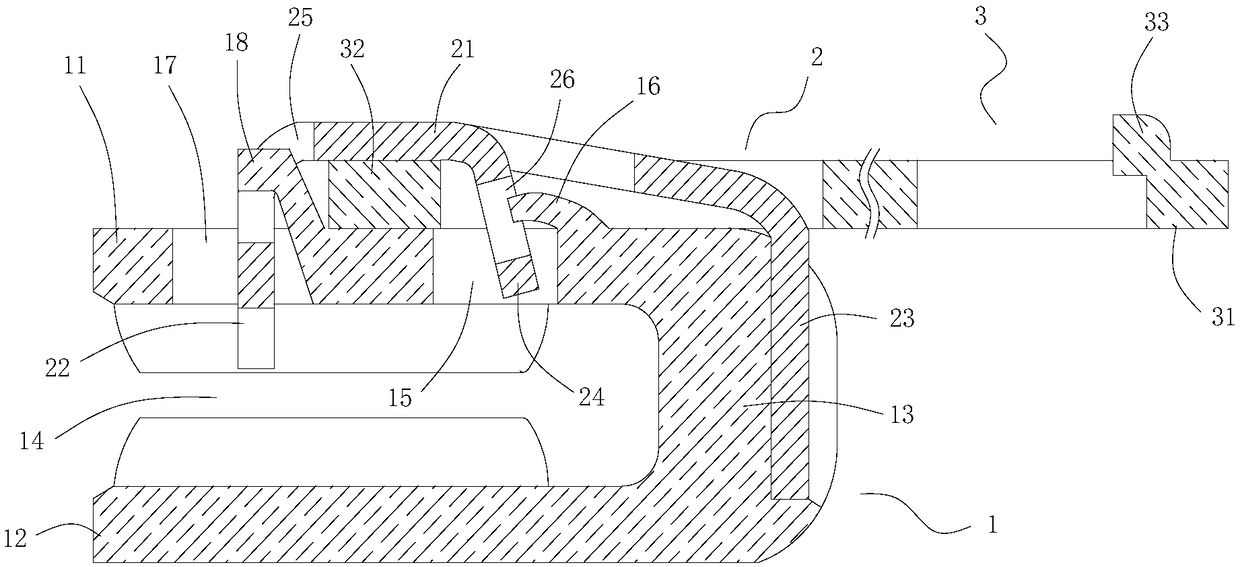

[0026] Such as Figure 1 to Figure 3 As shown, a self-locking slider includes a slider body 1, a leaf spring 2 and a pull piece 3, and these parts can be formed by stamping or machining.

[0027] The slider body 1 includes an upper wing 11 , a lower wing 12 and a guide post 13 , and the guide post 13 connects the upper wing 11 and the lower wing 12 into one body to form a chain element guide groove 14 through which the chain elements pass. An engaging hole 15 is provided at the central position of the upper wing 11 away from the front side, and a front protrusion 16 protruding from the upper surface of the upper wing 11 is formed at the front end of the engaging hole 15 . A claw hole 17 is provided at a central position away from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com