A braced loop reactor

A loop reactor and brace technology, applied in the field of brace loop reactor, can solve the problems of poor resistance to toppling moment, increased investment cost, unfavorable energy saving and emission reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

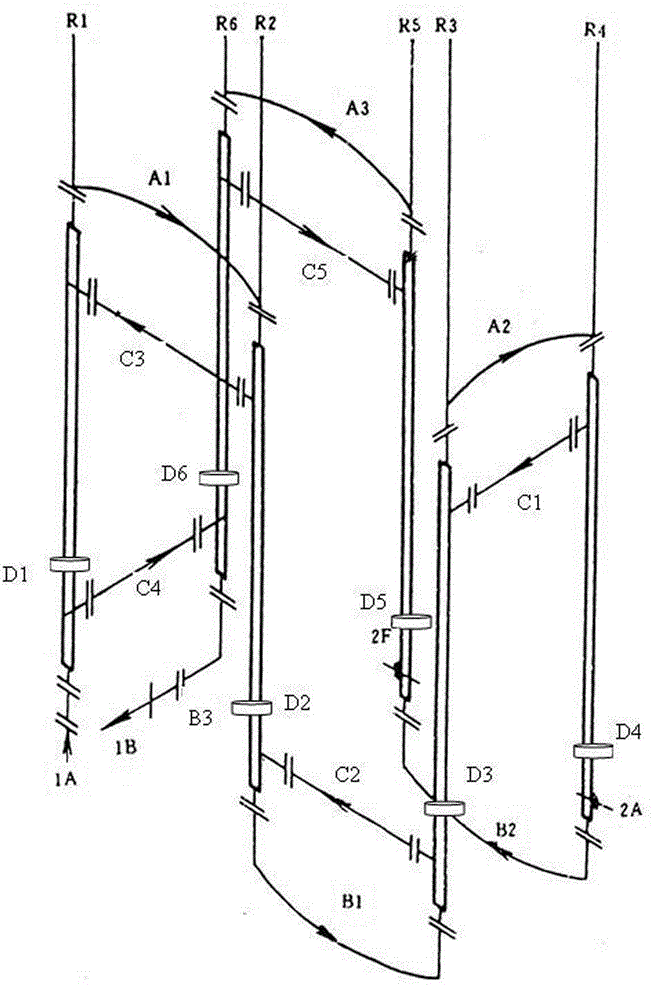

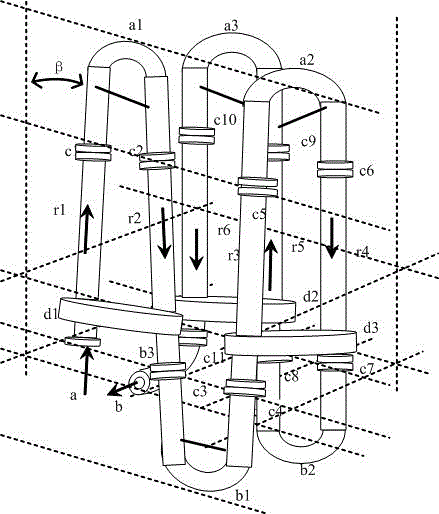

[0045] One of the specific implementations of a kind of diagonally braced loop reactor of the present invention, such as figure 2 and image 3 As shown, there are several bushings r1, r2, r3, r4, r5, r6, jacket connecting pipes, elbows a1, a2, a3, b1, b2, b3 and mounting supports d1, d2, d3, The casing includes an inner tube and an outer tube, and the elbow and the inner tube are sequentially connected in series to form a communication channel for conveying and reacting reaction materials. The outer pipe is connected, and the jacket flow channel formed between the inner pipe and the outer pipe is connected in series to form a communication flow channel for transporting cooling medium, wherein a is the reactant material flow inlet, and b is the reactant material flow outlet. The above technical features are the same as the structure of the loop reactor in the prior art. A diagonally braced loop reactor of the present invention also has other basic structures of the loop reac...

Embodiment 2

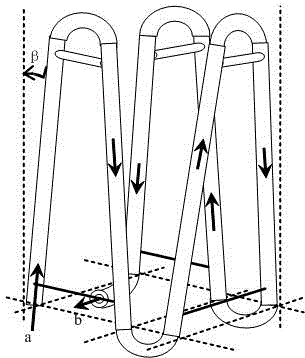

[0051] The second embodiment of a diagonally braced loop reactor of the present invention, as Figure 4 and Figure 5 As shown, the main technical solutions of this embodiment are the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 1 is that the inclined casing includes an upper cylinder, a middle cylinder and a lower cylinder, at least one section of the upper cylinder, the middle cylinder and the lower cylinder is The cylinder is inclined, and the inclined installation angle β between the inclined cylinder and the vertical center line is set to 2°-10°.

[0052] Specifically, the inclined installation angles β of the inclined cylinders provided in the inclined sleeve are not equal.

[0053] Specifically, each section of cylinder is connected by butt flange or butt welding. c1, c2, c3, c4, c5, c6, c7, c8, c9, c10, c11, h1, h2 s...

Embodiment 3

[0055] The third specific embodiment of a diagonally braced loop reactor of the present invention, the main technical scheme of this embodiment is the same as that of embodiment 2, and the features not explained in this embodiment are explained in embodiment 2, No further details will be given here. The difference between this embodiment and embodiment 2 is: as Figure 4 As shown, the sleeves r1 and r2 are selected, wherein the upper cylinders r11 and r21 are inclined cylinders, the lower cylinders are inclined cylinders, and the middle cylinders r12 and r22 are vertical cylinders or inclined cylinders . in Figure 4 The lower cylinder is not shown in the figure. From the perspective of the upper cylinder r11 and r21 and the middle cylinder r12 and r22 of the combined casing r1 and r2, the distance between the lower ends of the middle cylinder r12 and r22 is greater than the distance between the upper ends of the upper cylinder r11 and r21 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap