Light-emitting diode (LED) light source device

A technology of light-emitting diodes and light source devices, which is applied to electrical components, electric solid-state devices, circuits, etc., and can solve problems such as inability to adjust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

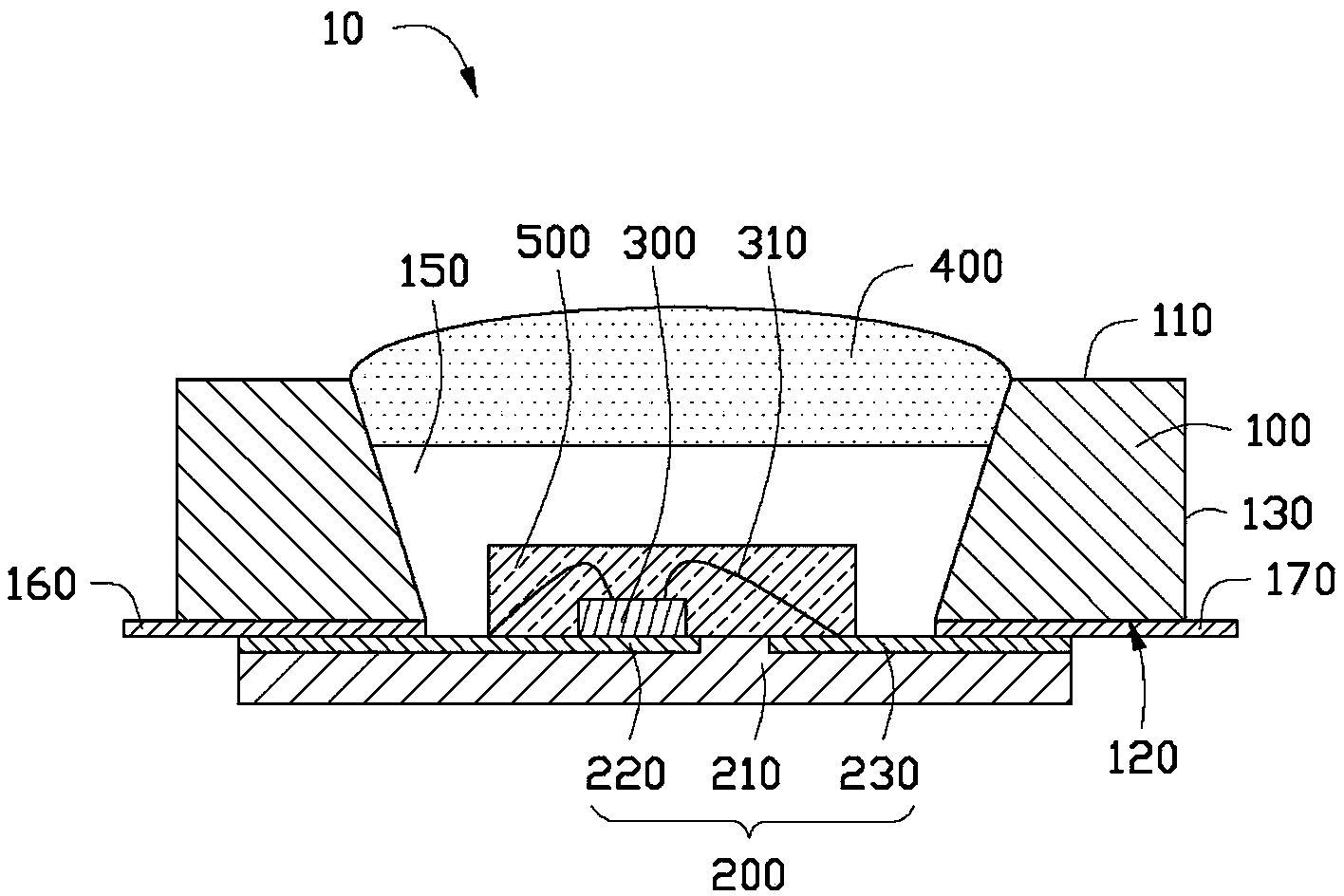

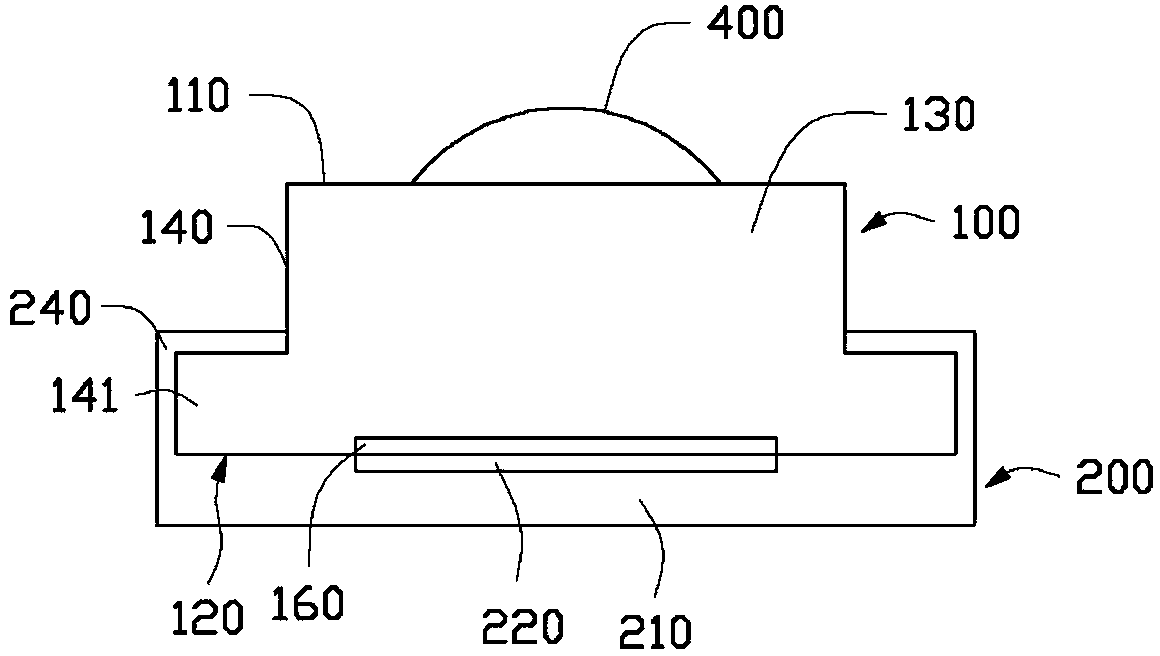

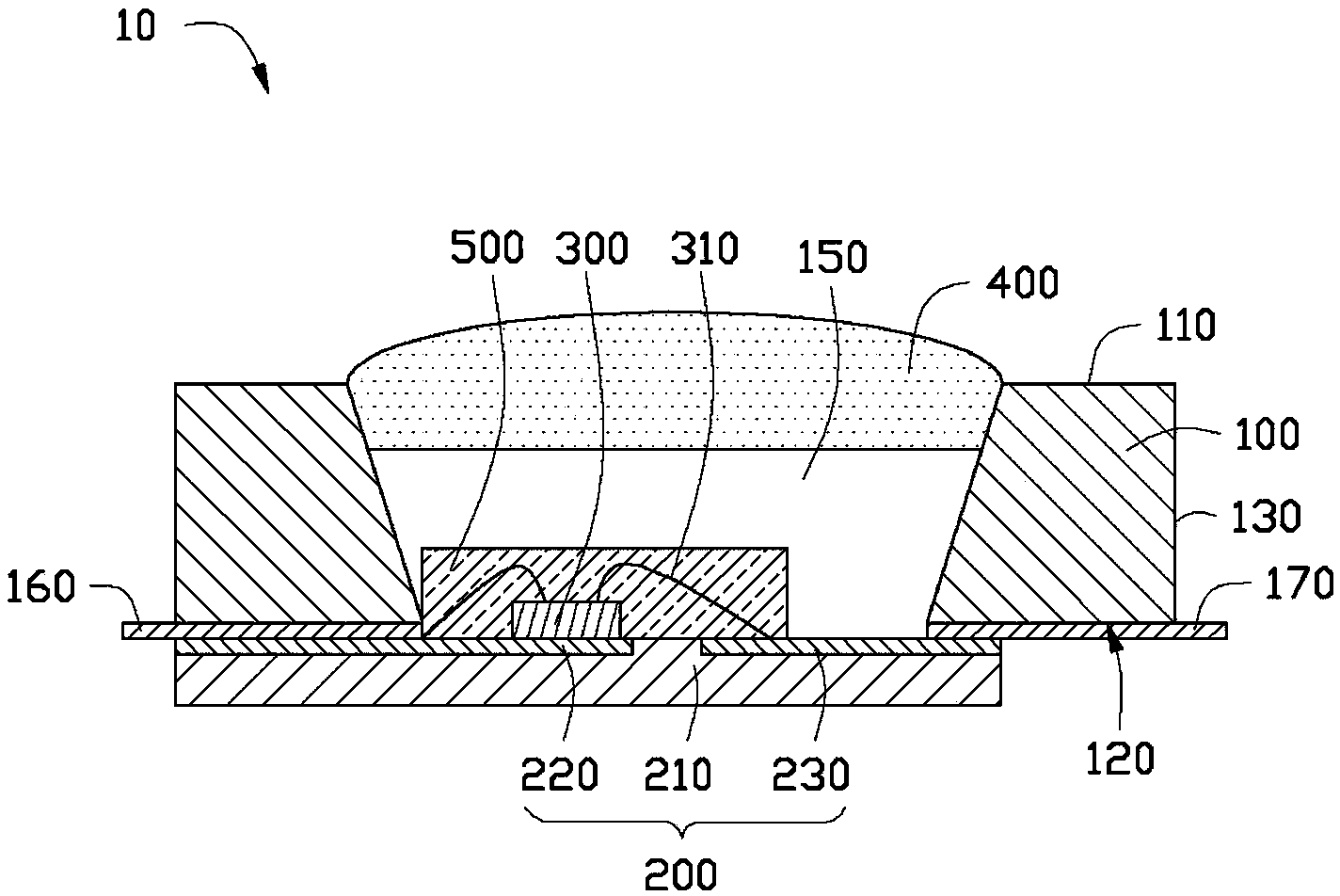

[0033] see figure 1 as well as figure 2 A light-emitting diode light source device 10 provided in a preferred embodiment of the present invention includes a base 100, a base plate 200 disposed on the base 100, a light-emitting diode chip 300 disposed on the base plate 200, and a cover. The phosphor layer 400 of the LED chip 300 is described above.

[0034] The base 100 includes a top surface 110 , a bottom surface 120 , two opposite end surfaces 130 and two opposite side surfaces 140 . The base 100 runs through the entire base 100 from the top surface 110 along the bottom surface 120 to form an accommodating groove 150 . The accommodating groove 150 is used to provide an accommodating space for the LED chip 300 and the phosphor layer 400 and to set the light field of the LED light source device 10 . The inner surface of the accommodation groove 150 is an inclined surface, which extends from the top surface 110 to the bottom surface 120 and inclines inward along the radial ...

Embodiment approach 2

[0044] see Figure 5The difference between the LED light source device 20 provided in the second embodiment of the present invention and the LED light source device 10 provided in the first embodiment is that no electrodes are formed on the bottom surface of the base 100a, and the third electrode 220a and the third electrode 220a on the bottom plate 200a One ends of the four electrodes 230a respectively extend out of the bottom plate 200a for connection with external circuits. The base 100a is movably disposed on the base plate 200a, and can slide relative to the base plate 200a, so as to adjust the relative position of the phosphor layer 400 and the LED chip 300 on the base plate 200a.

[0045] Compared with the prior art, the light-emitting diode light source device of the present invention is provided with a phosphor layer with non-uniform thickness distribution, and by changing the relative position of the light-emitting diode chip and the phosphor layer, the light-emittin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com