Sliding type spring stamping die ejecting mechanism

An ejection mechanism and sliding technology, which is applied in forging/pressing/hammering machinery, manufacturing tools, forging/pressing/hammer devices, etc., can solve the problems of unable to produce normally and increase the process, so as to reduce the scrap rate and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

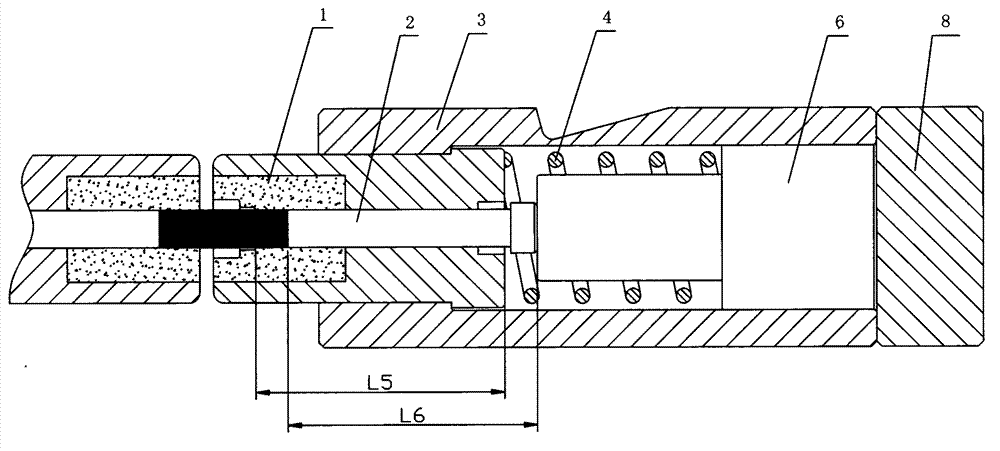

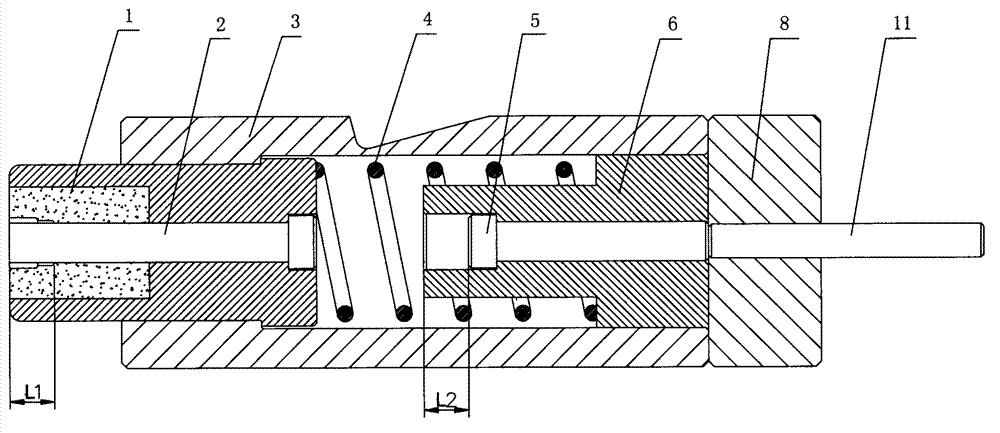

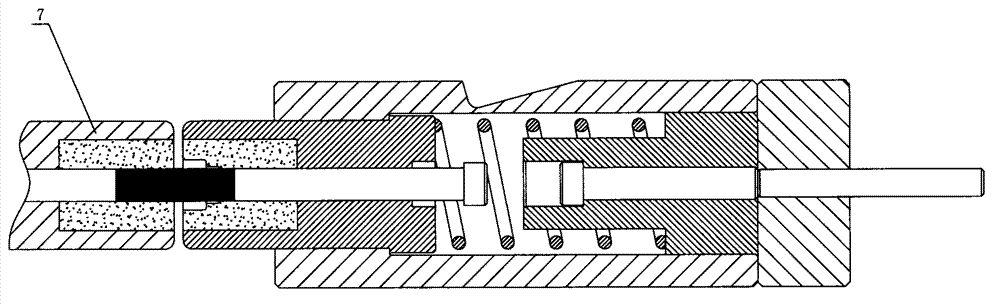

[0016] like figure 2 , Figure 6 and Figure 7 Shown is a sliding type spring die ejection mechanism, including a mold cover 3, a backing plate 8 is provided on one end surface of the mold cover 3, a spring pad 6 is provided on the backing plate 8 in the mold cover 3, and a spring pad 6 is provided on the spring pad 6. There is a spring 4, and the spring pad 6 includes a large bottom cylinder 6-2 and an upper small cylinder 6-1, the small cylinder 6-1 is located inside the spring 4, and the spring pad formed by the large cylinder 6-2 and the small cylinder 6-1 Step surface 14 places the end face of the spring, the top of the spring 4 is provided with an alloy die 1, the alloy die 1 is provided with a die step, and the inside of the die sleeve 3 is provided with a die sleeve step. A forming hole 9 is provided, and a thimble 2 and a thimble hole 16 for placing the thimble 2 are arranged inside the inner forming hole 9 of the alloy die 1. 2. The height of the head is the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com