A robotic arm system based on stereo vision servo and its real-time calibration method

A calibration method and technology of a robotic arm, applied in the field of robotics, can solve the problems of low precision, high precision, and high cost, and achieve the effect of precise calibration and precise operation tasks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

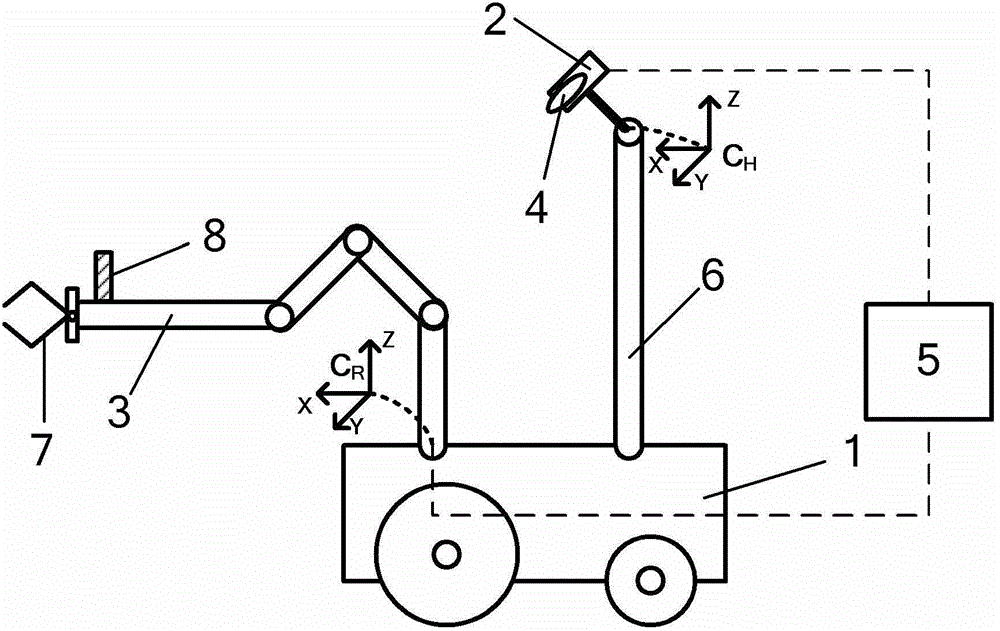

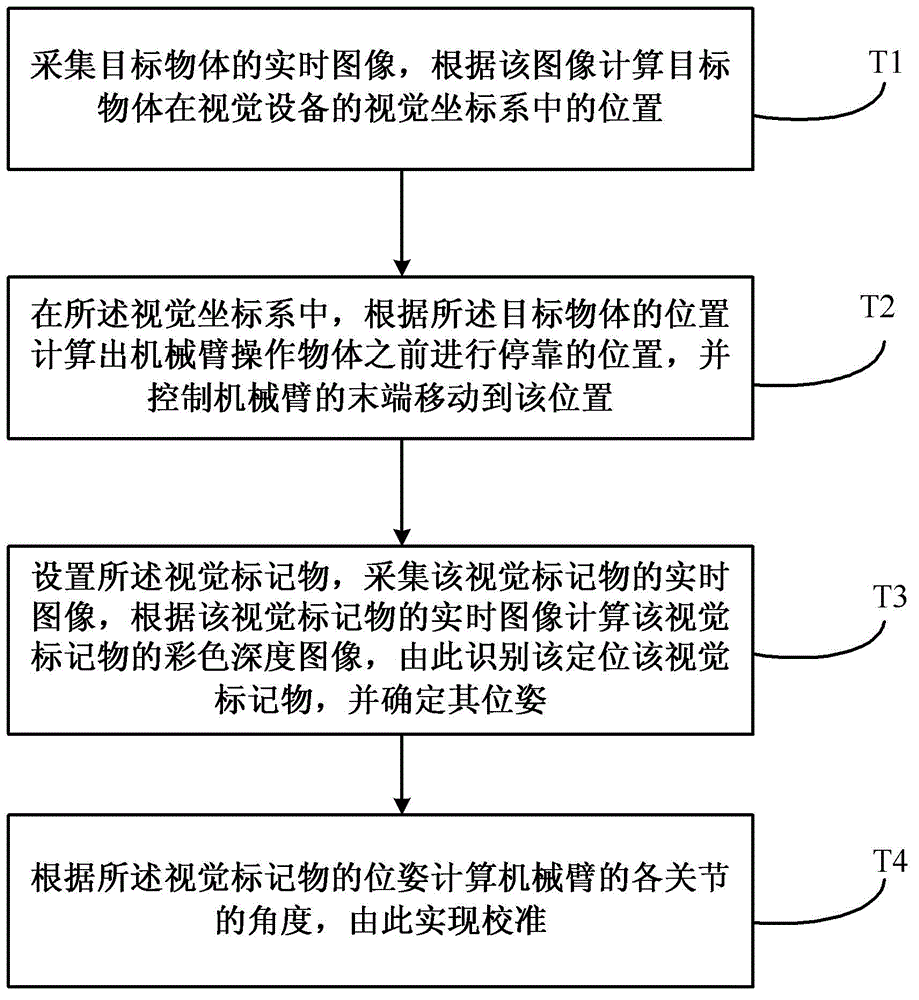

[0020] The manipulator system of the present invention is a part of the robot and is used to operate the target object. The robot has a body, and the manipulator system includes a manipulator, a vision device and a main control device. Wherein, the mechanical arm includes a plurality of connecting rods and joints between the connecting rods, and also includes a fixing device for fixing on the robot body. Since the joints between the connecting rods have degrees of freedom of movement, the mechanical arm has multiple degrees of freedom of movement. In addition, each of the above joints includes a joint controller for controlling the movement position of the joint. In addition, there is an actuator at the end of the robot arm, and the position and angle of the actuator relative to the arm joint of the robot arm are calibrated by a robot arm coordinate system. The origin of the mechanical arm coordinate system is located at the fixing device between the mechanical arm and the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com