Correction method and device of flatness of metal plate

A correction method and a correction device technology, which are applied in the field of mechanical processing technology, can solve problems such as the inability to effectively solve the bending of metal plate parts again, and achieve the effect of ensuring the effect of correcting shape dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

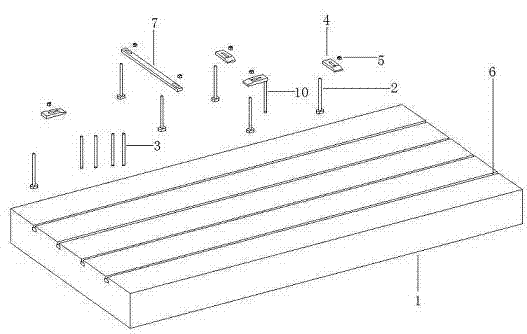

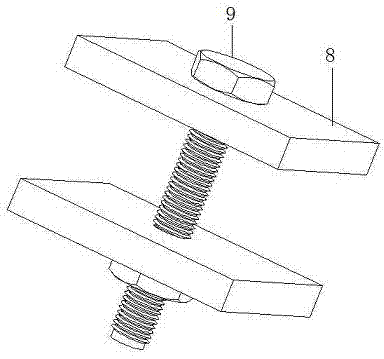

[0031] Below by embodiment, technical solution of the present invention is described further in conjunction with accompanying drawing:

[0032] A method for correcting the flatness of a metal plate, suitable for correcting the flatness of a bent metal plate, comprising the following steps:

[0033]a. Suspend the lower end of the metal plate, select several fixed points along the outer edge of the metal plate to fix it on the reference platform 1, all fixed points have the same fixed height.

[0034] b. Measure the height of each point on the sheet metal with a measuring tool, record the height value of the detection point, compare it with the height of the fixed point, mark the depression point and calculate the depression depth.

[0035] c. Place the jack under the depression of the metal plate, first use the jack to lift the depression to the same height as the fixed point, then continue to raise the jack, and continue to lift the depression up for a certain distance.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com