Aeration facility with downward-bent base slab

A bottom plate, curved technology, applied in the field of curved air aeration facilities under the bottom plate, can solve the problems of the influence of the flow state of the downstream sump, the length of the air aeration protection, and the poor flow state, etc. The effect of improving the state and avoiding the backwater of the cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

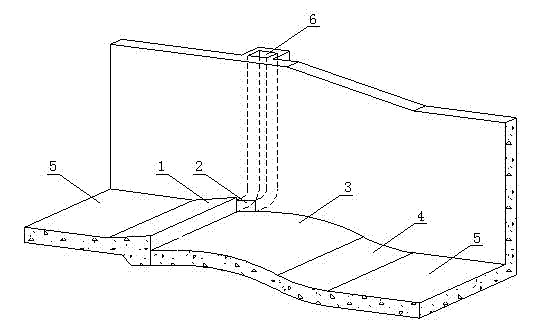

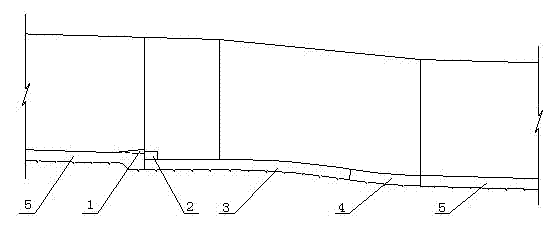

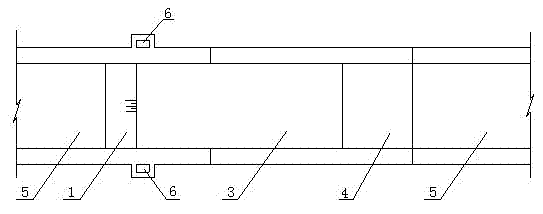

[0019] Such as figure 1 , figure 2 with image 3 As shown, the floor-curved aeration facility is a part of the floor 5 of the flood discharge building, that is, the floor-curved aeration facility is embedded in the floor 5 as a whole.

[0020] The under-bent type aeration facility at least includes an aeration sill 1, a ventilation hole 2, an under-bent section 3 and an anti-arc section 4, and the aeration sill 1, the under-bend section 3 and the anti-arc section 4 are sequentially spliced together, that is The upstream of the aeration ridge 1 is connected to the upper end of the bottom slope 5, and its downstream is connected to the upstream of the bottom bend section 3, the upstream of the anti-arc section 4 is connected to the upstream of the bottom bend section 3, and the downstream of the anti-arc section 4 is connected to the bottom slope 5 The lower end is connected, and the ventilation hole 2 is arranged on both sides of the downstream of the aeration rim 1 .

[...

Embodiment 2

[0027] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that a section of horizontal section is set between the aeration sill 1 and the lower bending section 3 of the bottom plate, its length is 3.5 meters to 10 meters, and its length is proportional to the water flow Fr value. Proportional, that is, the greater the value of the water flow Fr, the greater the length, and the horizontal section makes the aeration ridge 1 pick up the water and fall on the middle and rear part of the lower curved section 3 of the bottom plate.

[0028] The invention is not only suitable for discharge structures with relatively gentle bottom slopes, which can eliminate water accumulation in air-entrained cavities, but also suitable for relatively steep bottom slopes, which can maintain good water flow state at various water depths.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Central angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com