Pattern spraying and marking device for plate type workpieces

A technology for marking equipment and workpieces, applied in spraying devices, coatings, devices for coating liquid on surfaces, etc., can solve problems such as high labor intensity, pollution, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

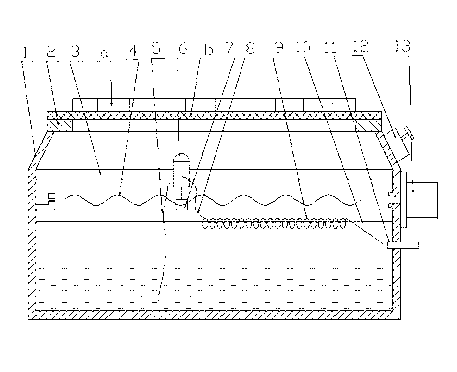

[0009] In the figure, the marking equipment of this kind of board workpiece includes grooved cylinder 1, flange notch 2, guide rail 3, lead screw 4, paint suction pipe 5, pneumatic nozzle 6, lead screw nut 7, feeder Gas hose 8, hose hanging ring 9, hanging ring guide wire 10, air intake pipe joint 11, control box 12, frequency conversion speed regulating motor 13, a. workpiece b. long groove, and the guide rail 3 is installed on the grooved cylinder Inside the trough-shaped cylinder 1 below the mouth of the body 1, the pneumatic nozzle 6 is movably installed on the guide rail 3, the screw 4 and the guide rail 3 are installed in the trough-shaped cylinder 1 in parallel, and hung on the guide wire 10 of the hanging ring. There is a hose hanging ring 9, the hanging ring guide steel wire 10 is fixedly installed in the grooved cylinder 1 in parallel with the guide rail 3, the frequency conversion motor 13 is fixedly installed on the outside of the grooved cylinder 1, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com