Mechanism of novel threading tool

A thread turning tool, a new type of technology, is applied to the accessories of tool holders, thread cutting tools, and tools for lathes, etc. It can solve the problems of waste of tool head materials and fewer times of repeated sharpening, and achieves convenient installation and adjustment. The effect of less repeated sharpening times and short manufacturing and adjustment cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

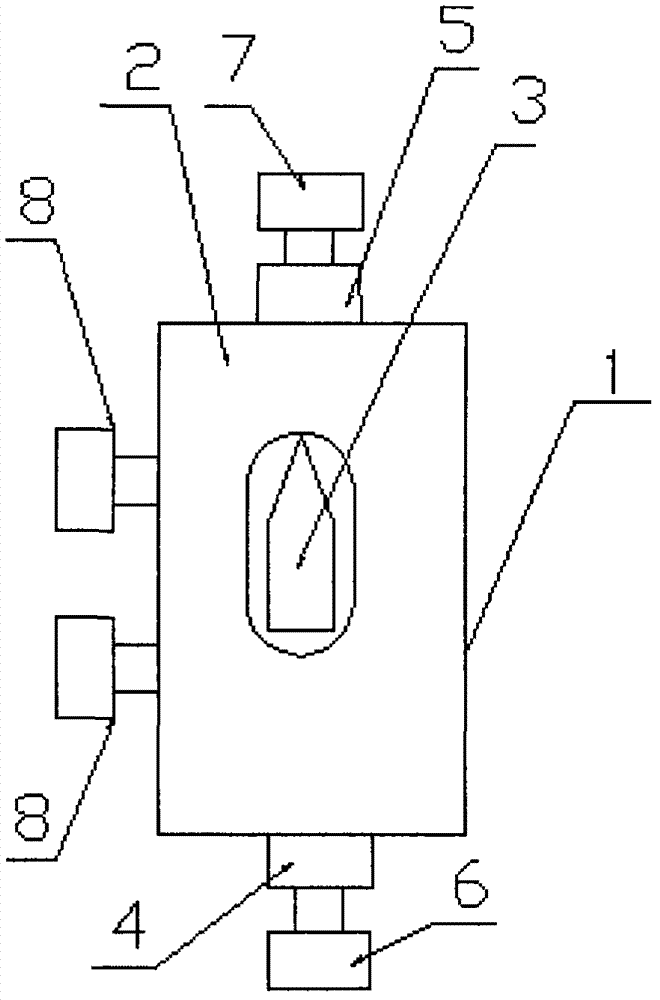

[0008] Make a hollow along the entire length of the shank of the knife bar 2, make a blind hole at the 2 heads of the knife bar, make a threaded through hole at the bottom of the blind hole, and make a hollow in the full length direction of the shank of the knife bar 2 It is perpendicular to the axis of the blind hole in the head of the tool bar, and the slider 1 is installed in the blind hole of the head of the tool bar 2, and a hole is opened on the waist of the slider 1, and at the same time, the threaded hole on the top communicates with the through hole on the waist , the through hole opened on the waist of the slider 1 is similar to the section of the threaded long cutter head 3, the threaded long cutter head 3 can pass through it smoothly, the slider 1 is installed in the blind hole of the head of the cutter bar, and the The through hole opened on the waist is aligned with the through-hole in the full-length direction of the handle of the knife rod, and the threaded long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com