Hydraulic centering cylinder with mechanical lockup function

A mechanical lock and function technology, applied in the direction of hydraulic steering gear, fluid pressure actuating device, etc., can solve the problems of deteriorating the driving stability of the vehicle and only elastic locking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

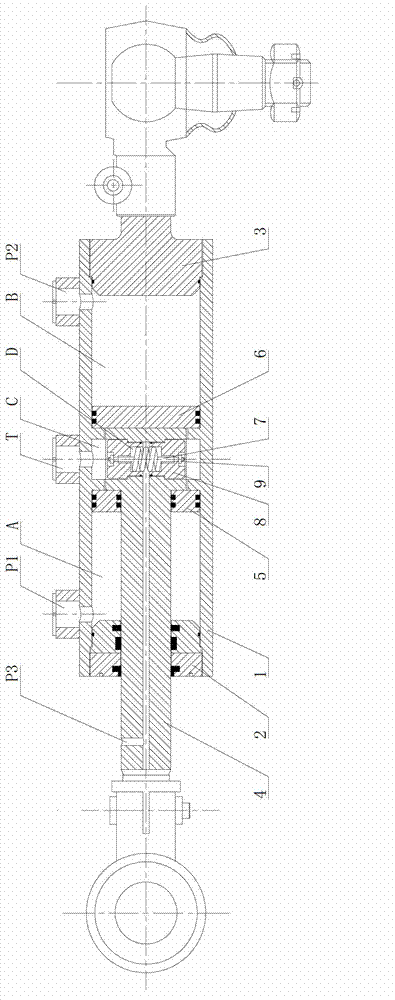

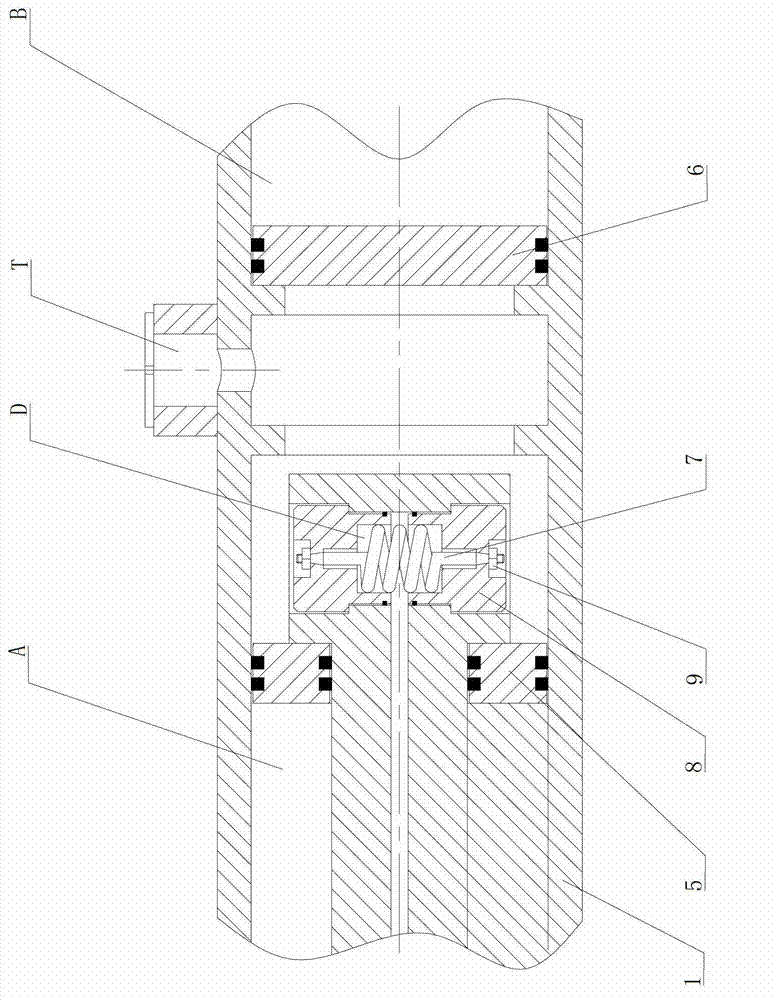

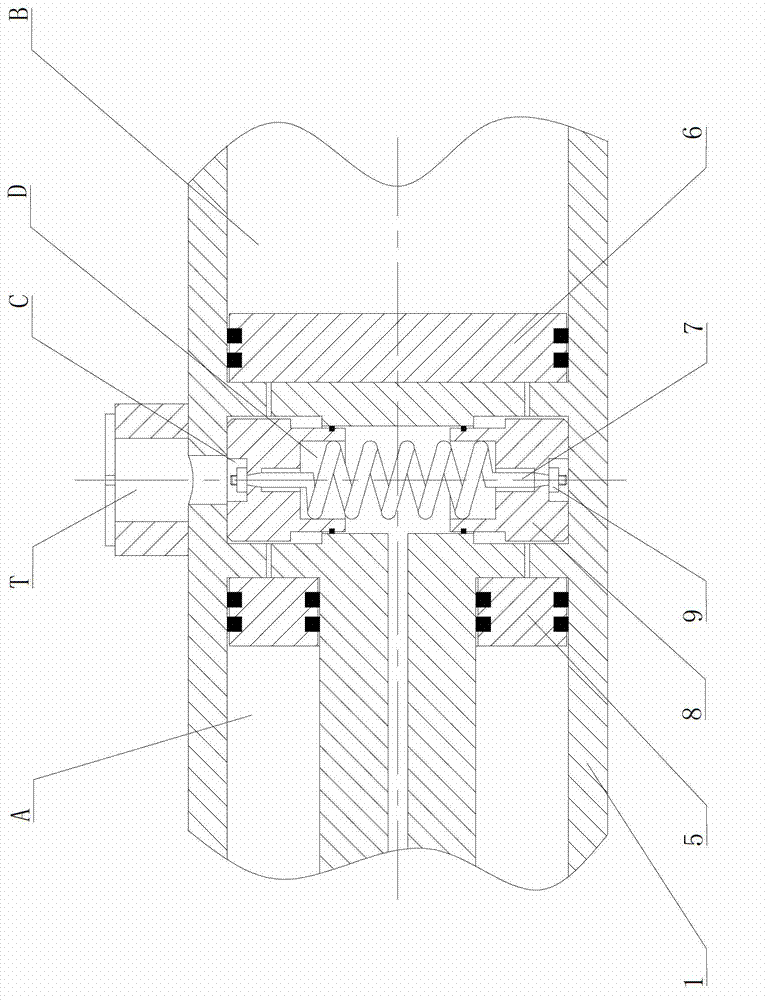

[0018] A hydraulic centering cylinder with mechanical locking function, including: cylinder block, piston rod, left cylinder end cover, right oil cylinder end cover, left floating piston, right floating piston; also includes: spring, locking piston and nut ;Such as figure 1 shown.

[0019] The hydraulic centering function is composed of cylinder block 1, left cylinder end cover 2 and right cylinder end cover 3, piston rod 4, left floating piston 5, right floating piston 6, etc. The two ends of the left oil cylinder end cap 2 and the right oil cylinder end cap 3 are internally threaded and sealed with the oil cylinder body 1 . The piston rod 4 is located in the oil cylinder body 1, and an annular boss is arranged at one end inside it. The left floating piston 5 and the right floating piston 6 are installed on both sides of the annular boss respectively. The middle of the oil cylinder block 1 is designed with left and right inner ring platforms which are matched with the annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com