Full-pressure high-speed exhausting air-supplying special valve

A special valve, high-speed technology, applied in safety valves, valve details, balance valves, etc., can solve the problems of unstable lever structure, jamming, easy water leakage and air leakage, etc., to improve discharge permeability, improve sealing performance, The effect of automatic sealing of the valve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

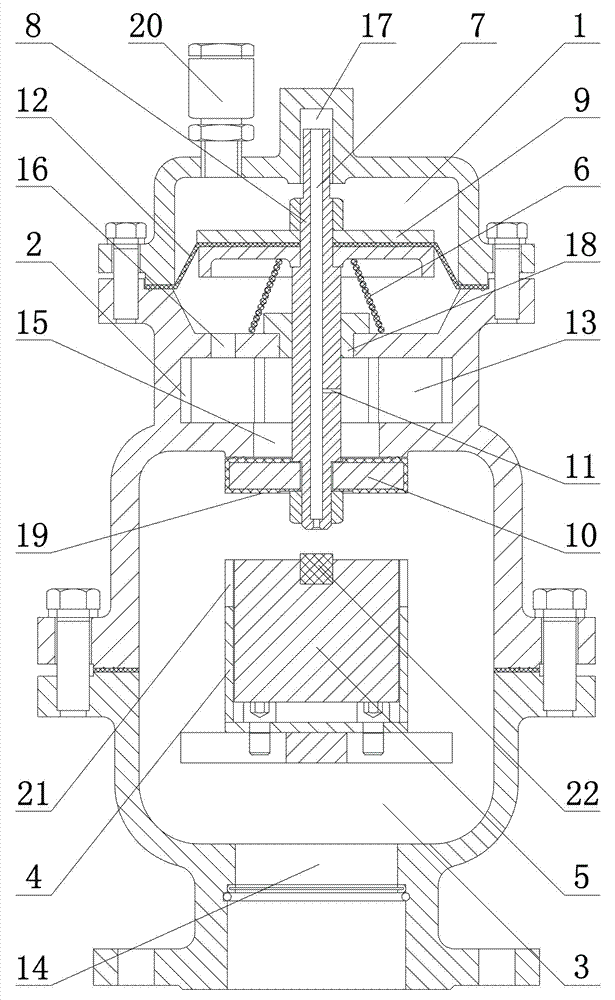

[0023] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

[0024] Such as figure 1 As shown, a full-pressure high-speed exhaust and air supplement valve includes a cylinder 1, an exhaust and air supplement chamber 2 arranged at the bottom of the cylinder 1, and a main valve chamber arranged at the bottom of the exhaust and air supplement chamber 2. body 3, a guide exhaust cylinder 4 arranged in the main valve cavity 3, a sealing floating body 5 arranged in the guide exhaust cylinder 4, a piston spring 6 and a main valve piston having a vertical through hole 7; The sealing floating body 5 is a cylindrical structure with an open bottom. The benefit of setting the exhaust and air supplement chamber 2 independently is to avoid interference from parts such as springs during exhaust or air supplement.

[0025] The main valve piston includes a piston rod 8 and a cylinder piston and a sealing baffle 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com