Frame assembly for sheet material

A frame and component technology, applied in the field of sheet components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

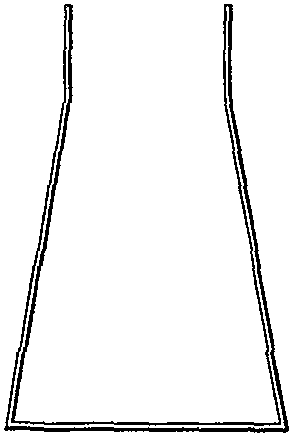

[0095] refer to figure 1 and 2 , the elongated extruded inner frame portion 10 has a recess 11 for receiving a sheet 12, such as glass. The inner frame portion 10 can fit around the periphery of the sheet (eg, the edge of a glass sheet).

[0096] The inner frame part has a neck 14 comprising a mouth 18 of the recess 11 and a base 16 . The edge of the sheet 12 is inserted into the recess 11 through the mouth 18 and is surrounded by a sealing and / or bonding material 20 arranged in the recess 11 . In the illustrated embodiment, the recess is filled with a silicone adhesive material 20 such that the edges of the sheet 12 are surrounded by the adhesive material 20 and are formed by the bond formed between the inner frame portion 10, the adhesive material 20 and the sheet 12. Knot stays in place.

[0097] Preferably, the adhesive material 20 is arranged in the recess 11 such that it is sandwiched between the mouth 18 and the sheet 12 to prevent the sheet 12 from contacting the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com