A new type of manual adjustment arm with automatic positioning and locking

A technology of automatic positioning and manual adjustment, applied in the field of manual adjustment arm, to achieve the effect of long service life, reduced maintenance cost and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

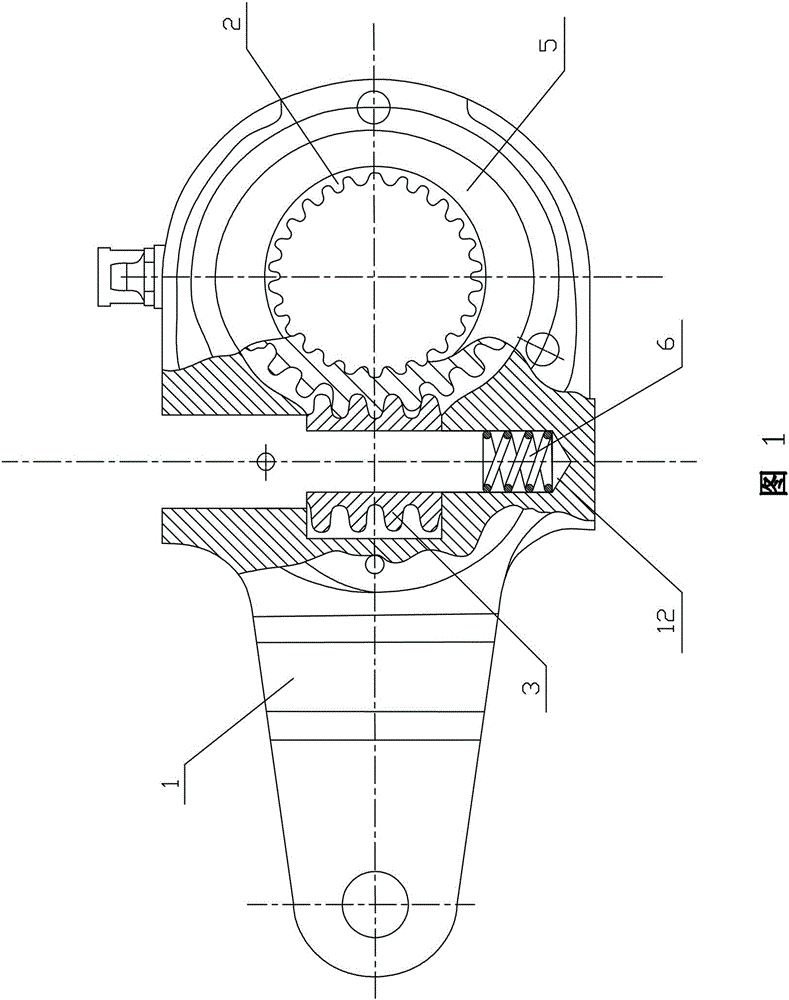

[0030] A new type of manual adjustment arm that can be automatically positioned and locked, refer to Figure 1 to Figure 3 , mainly consists of a housing 1, a worm wheel 2 installed in the housing 1, a worm 3 meshing with the worm wheel 2, and an adjustment shaft 4, and the housing 1 on both sides of the worm wheel 2 is respectively equipped with sealing plates 5. refer to figure 1 , the housing 1 is correspondingly provided with an upper installation hole 11 and a lower installation hole 12 connected with the inner hole of the worm 3, and a pressure spring 6 is arranged in the lower installation hole 12, the pressure spring 6 is made of imported high-quality m steel, elastic Good, it is used to adjust the rotation of axis 4 and position and press, and the effect is good.

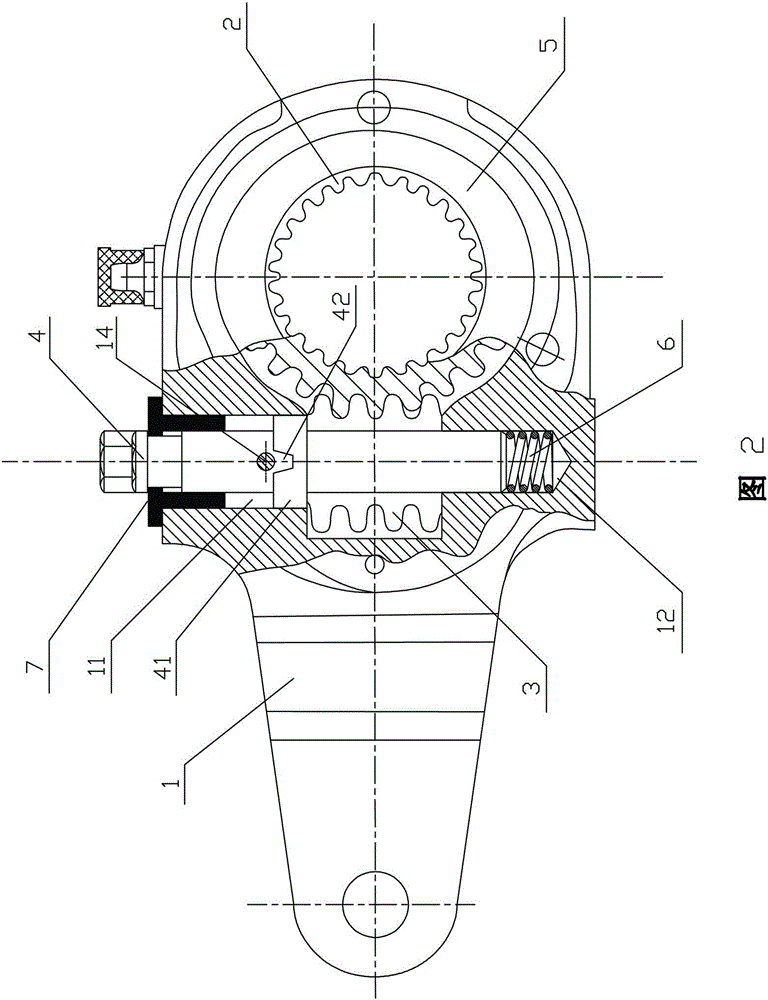

[0031] refer to figure 2 , the adjustment shaft 4 runs through the upper mounting hole 11 , the worm inner hole 3 and the lower mounting hole 12 , its upper end passes through the upper mounting hole 11 ...

Embodiment 2

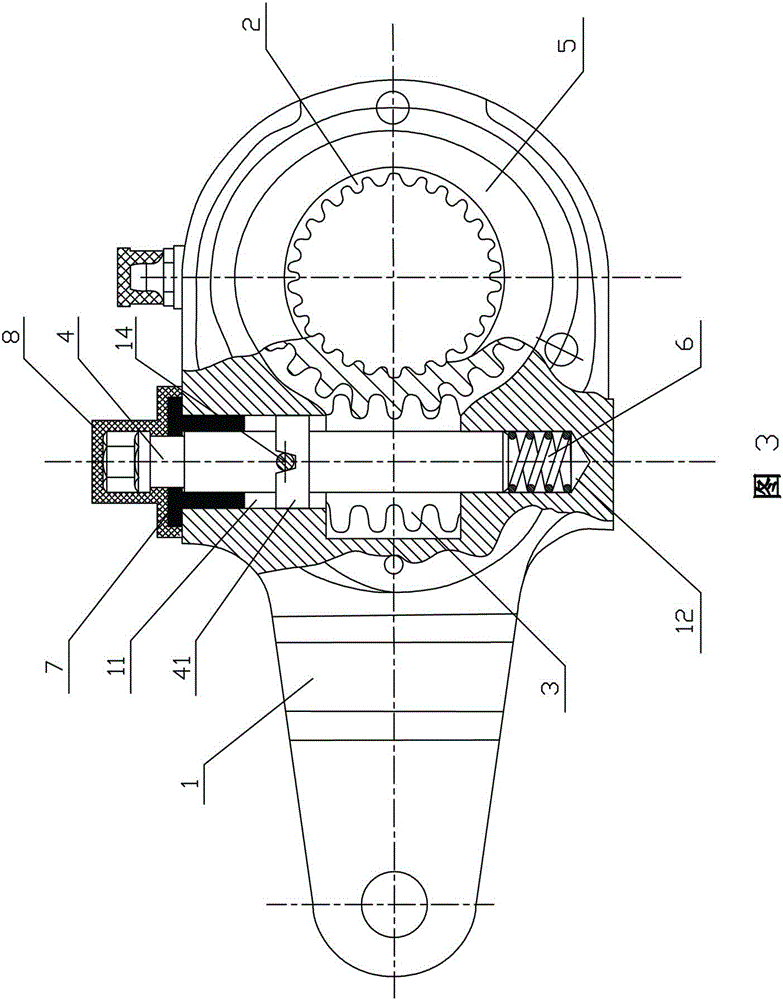

[0043] This embodiment is basically the same as Embodiment 1, the difference is that: the front and rear sides of the housing 1 are symmetrically expanded with a radial threaded hole 13 communicating with the upper mounting hole 11 and corresponding to the tooth groove 42, each M6 column-end set screws 14 are installed in the radially threaded holes 13 , and the ends of the column-end set screws 14 are snapped into the corresponding tooth grooves 42 .

[0044] The above are two specific embodiments of the present invention. The threaded hole 13 is provided only on the housing 1 , not limited to the above two methods, as long as it is located on the housing and cooperates with the tooth groove 42 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com