Liquid crystal panel manufacturing method, liquid crystal mixture and liquid crystal panel

A technology for liquid crystal panels and manufacturing methods, applied in liquid crystal materials, chemical instruments and methods, optics, etc., capable of solving problems such as the narrow application range of blue phase liquid crystals and the difficulty of blue phase liquid crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

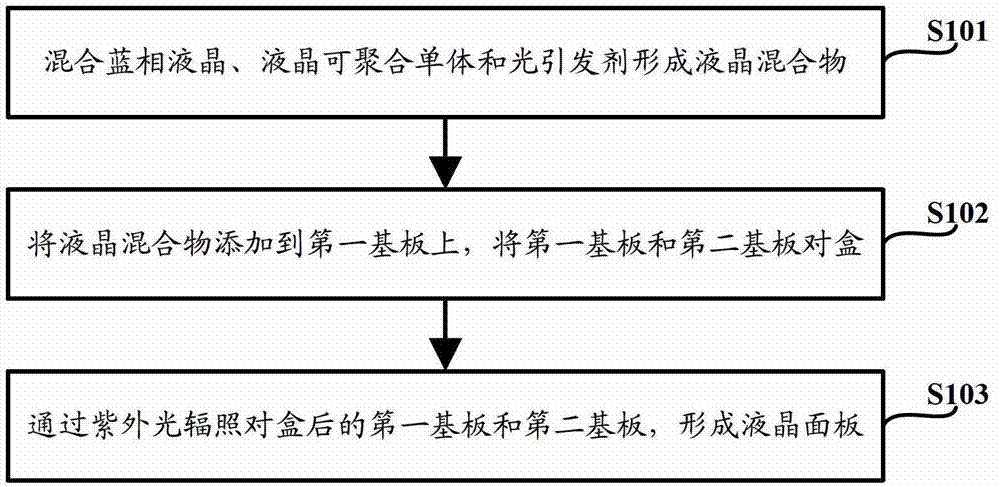

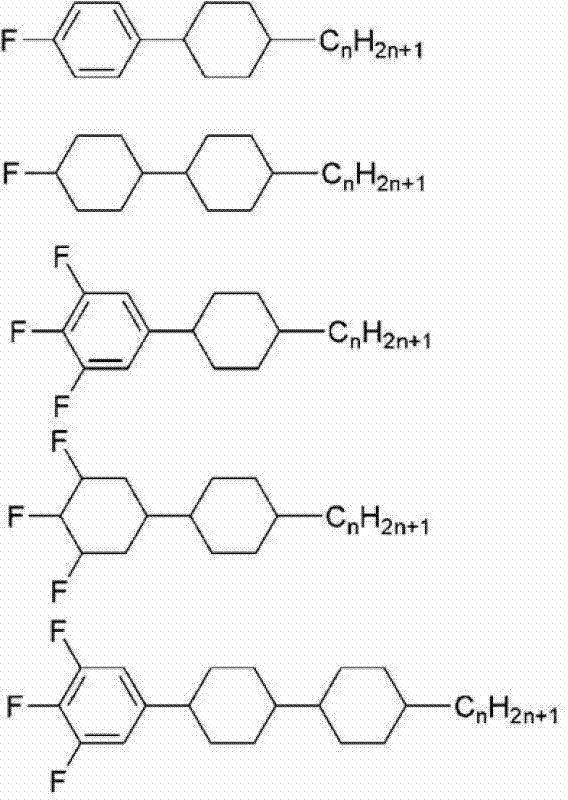

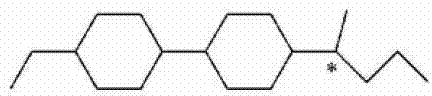

[0028] Embodiments of the present invention provide a method for manufacturing a liquid crystal panel, a liquid crystal mixture, and a liquid crystal panel. The mixture formed by mixing blue-phase liquid crystals, liquid crystal polymerizable monomers, and photoinitiators is used as liquid crystal filling in the liquid crystal panel, and is made by ultraviolet polymerization. Liquid crystal polymerizable monomers are polymerized to form a polymer network. In the display operating temperature range, the blue phase liquid crystal is stabilized by the anchoring effect of the polymer network. In the ADS display mode, the electric field is distributed as a fringe field. In the off state, due to The blue-phase liquid crystal exists in a cubic lattice structure, and it is in a dark field before power-on. After power-on, due to the unique edge electric field distribution of ADS, the cubic lattice arrangement of the blue-phase liquid crystal is destroyed, and the liquid crystal molecules...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com