Conformal Mask Packaging Structure and Inspection Method

A packaging structure, conformal mask technology, applied in the direction of single semiconductor device testing, semiconductor/solid-state device testing/measurement, electrical components, etc., can solve the problem of poor substrate cutting, increased material waste, uneven conductive mask layer, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

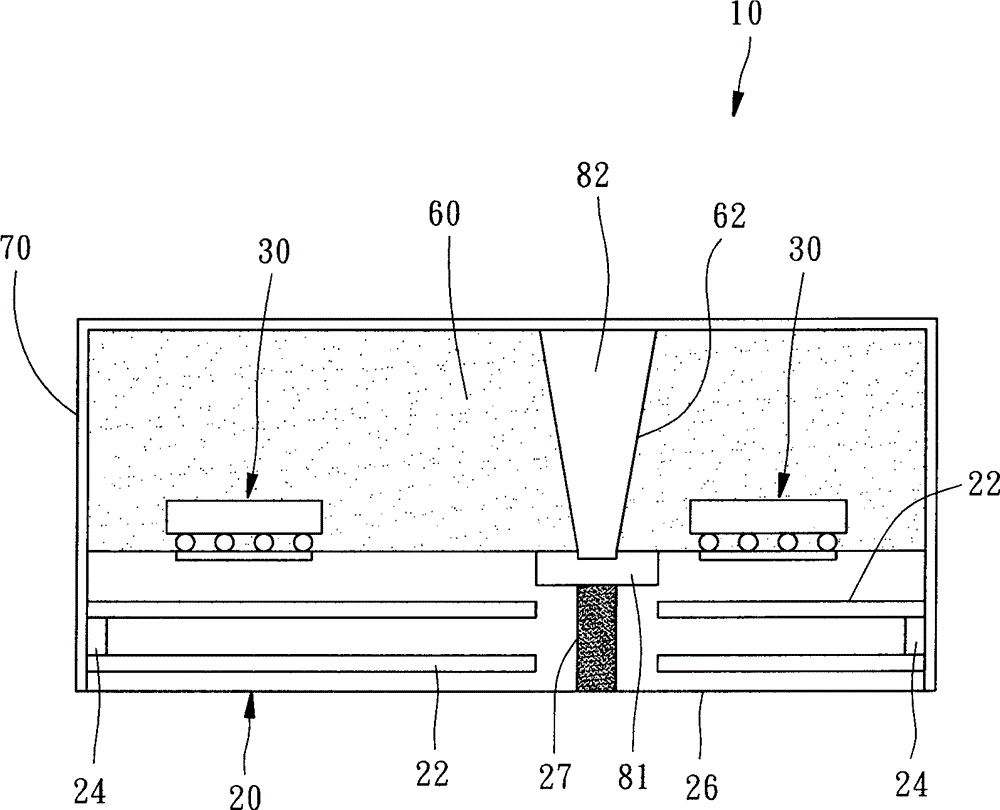

[0019] Please refer to the accompanying drawings, the conformal mask packaging structure 10 provided by a first embodiment of the present invention includes a substrate 20, at least one chip module 30 disposed on the substrate 20, and an encapsulant covering the chip module 30 60, and a conductive mask layer 70 for masking the encapsulant 60, wherein the number of the chip modules 30 is two in this embodiment.

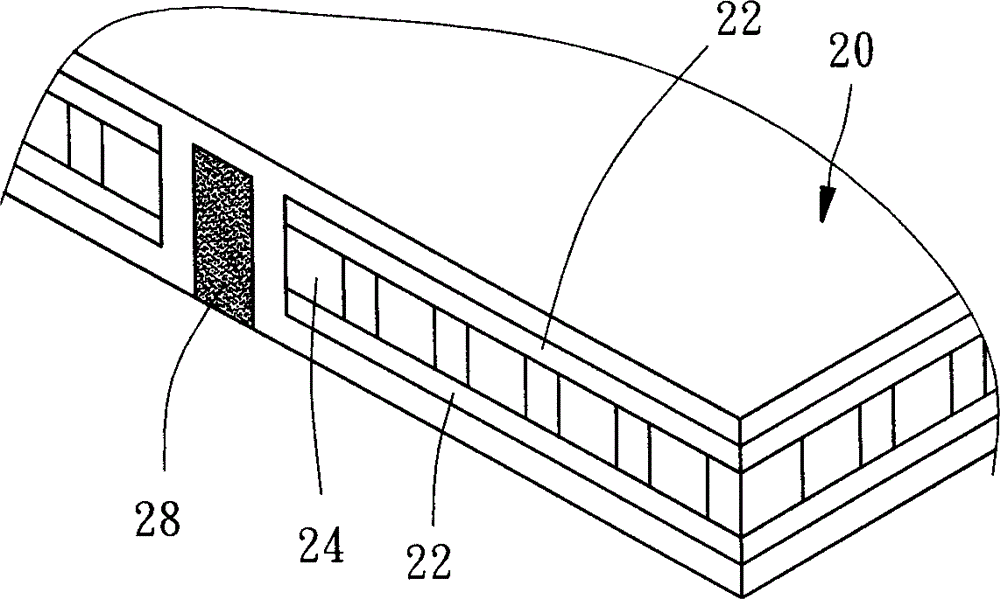

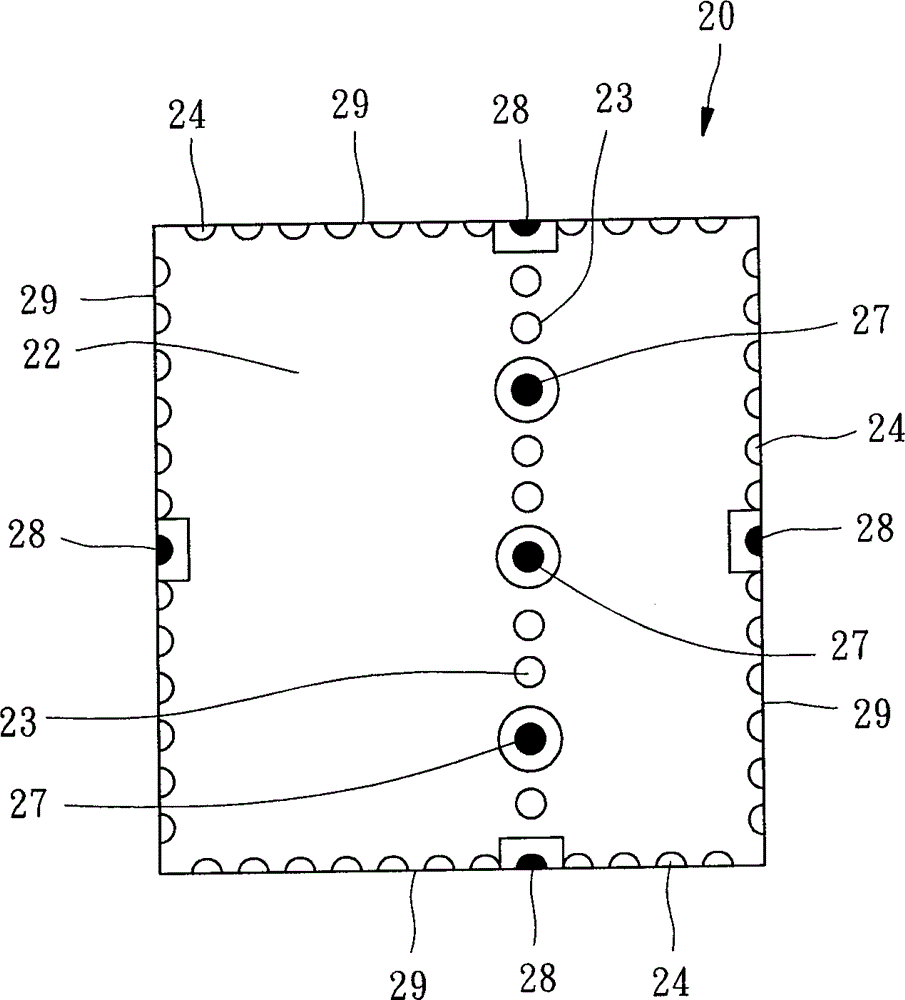

[0020] The substrate 20 is similar to the existing multi-layer printed circuit board, and its inner layer has at least one ground layer 22, and the substrate 20 has a plurality of ground vias (GroundVia) respectively pierced in the printed circuit board and electrically connected to the The inner grounding conductive structures 23, 24 of the grounding layer 22, the aforementioned grounding channels can adopt through holes, blind holes, buried holes or other similar structures and combinations thereof. The inner grounding conductive structures 23, 24 generally refer to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com