Heat recovery and reuse system for glass production line

A glass production line and heat recovery technology, applied in glass production, glass furnace equipment, glass manufacturing equipment, etc., can solve the problems of polluting the environment and easily causing the greenhouse effect, so as to reduce energy waste, benefit the environment and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

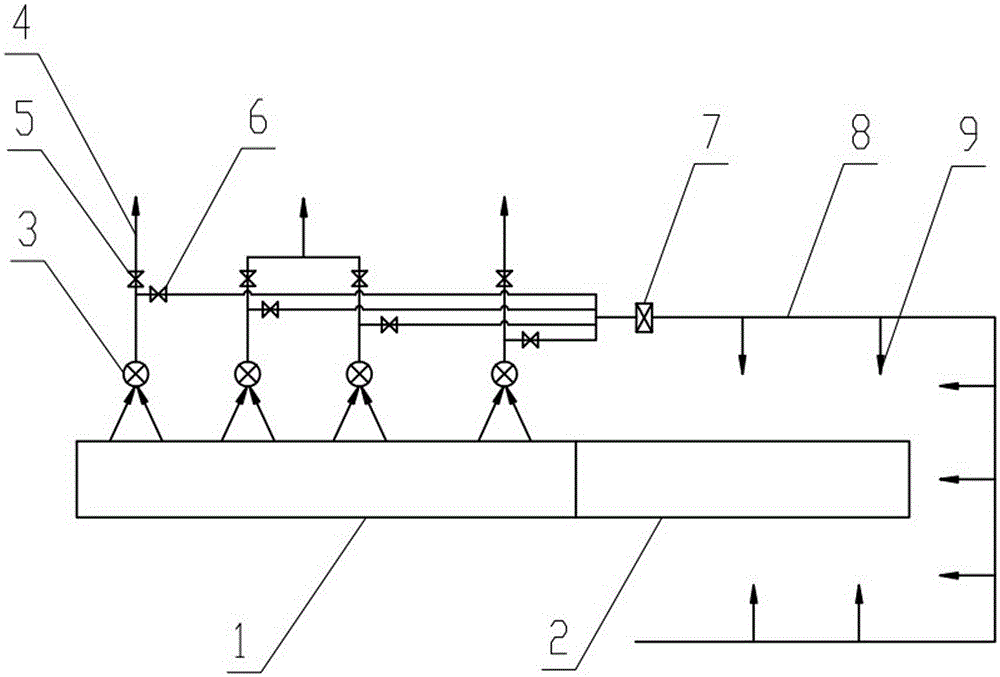

[0019] Such as figure 1 It can be seen from the illustrated embodiment that the heat recovery and reuse system of the glass production line according to the present invention includes an annealing fan 3, an emptying pipeline 4 and a heat exhausting pipeline 8; the emptying pipeline 4 communicates with the annealing kiln 1 through the annealing fan 3, The emptying pipe 4 is connected with the heat exhausting pipe 8; the outlet end of the emptying pipe 4 is provided with an emptying valve 5, and its inlet end is connected with the annealing fan 3; the connection point between the emptying pipe 4 and the heat exhausting pipe 8 is located 3 and the exhaust valve 5; the inlet end of the heat exhaust pipe 8 is provided with a heat exhaust valve 6, and the outlet end is provided with a heat exhaust air outlet 9; the outlet end of the heat exhaust pipeline 8 circles around the finished product section 2; the heat exhaust air outlet The number of 9 is 5-8, and they are evenly distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com