Hydraulic buffering adjustable glass clamp

A hydraulic buffering and adjustable technology, applied in the installation of window glass, switches with brakes, door/window accessories, etc., can solve the problems of reducing installation efficiency, increasing installation cost, increasing installation difficulty, etc. Simple, reduced installation costs, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The accompanying drawings are for illustrative purposes only, and should not be construed as limitations on this patent; in order to better illustrate this embodiment, certain components in the accompanying drawings will be omitted, enlarged or reduced, and do not represent the size of the actual product; for those skilled in the art It is understandable that some well-known structures and descriptions thereof may be omitted in the drawings.

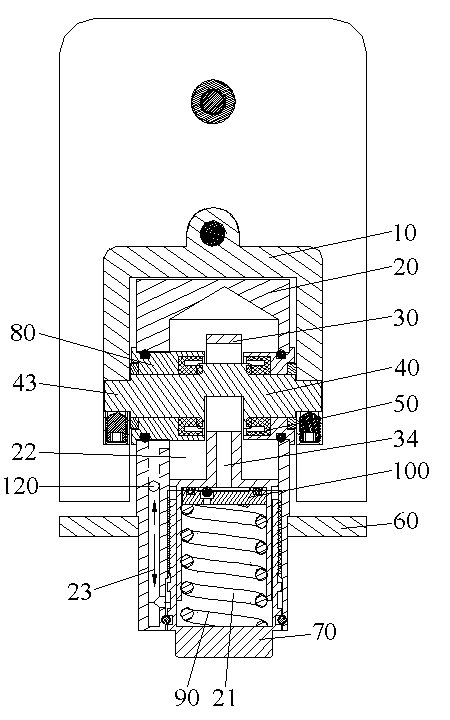

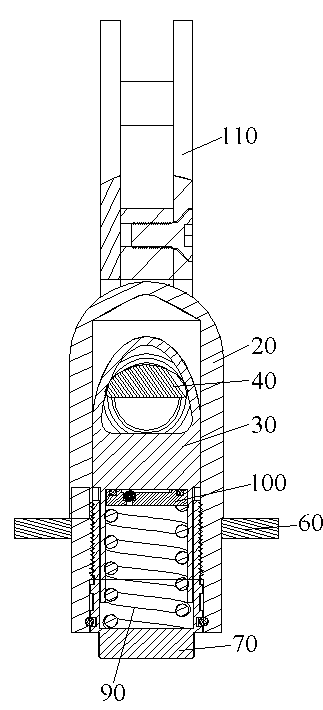

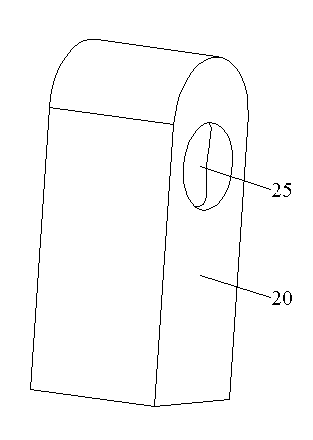

[0045] Such as figure 1 , 2 As shown, a hydraulically buffered adjustable glass clamp includes a movable seat 10 and a panel 110 for clamping the glass door. cylinder liner 70, piston liner 30, protruding shaft 40, spring 90 and one-way throttle valve 100;

[0046] The protruding shaft 40 is rotatably connected with the piston sleeve 30, and the two ends of the protruding shaft 40 are fixed with the movable seat 10; the oil cylinder sleeve 70 is sealed and fixed with the oil cylinder seat 20, and the oil cylinder sleeve 70 is sl...

Embodiment 2

[0061] Such as Figure 16 As shown in -18, the fixed glass 150 is fixed to the wall 130, and the glass door 140 is between the two fixed glasses 150. In this embodiment, the panel 110 is a double-leaf panel, and the two panels 110 clamp the fixed glass 150 and the glass door respectively. 140, the form is suitable for the 180 degree rotation of glass door 140 like this. The working principles of the remaining structures of this embodiment are the same as those of Embodiment 1, and will not be described here.

Embodiment 3

[0063] Such as Figure 19 As shown, the panel 110 is also a double-leaf panel. In this embodiment, it is suitable for the 135-degree rotation of the glass door. The working principle of the rest of the structure of this embodiment is the same as that of Embodiment 2, and will not be described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com