Cutting method of alumina substrate

An alumina and substrate technology, applied in glass cutting devices, fine working devices, glass manufacturing equipment, etc., can solve the problems of wear of scoring wheel, hard ceramic substrate, etc., and achieve the effect of small breaking load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

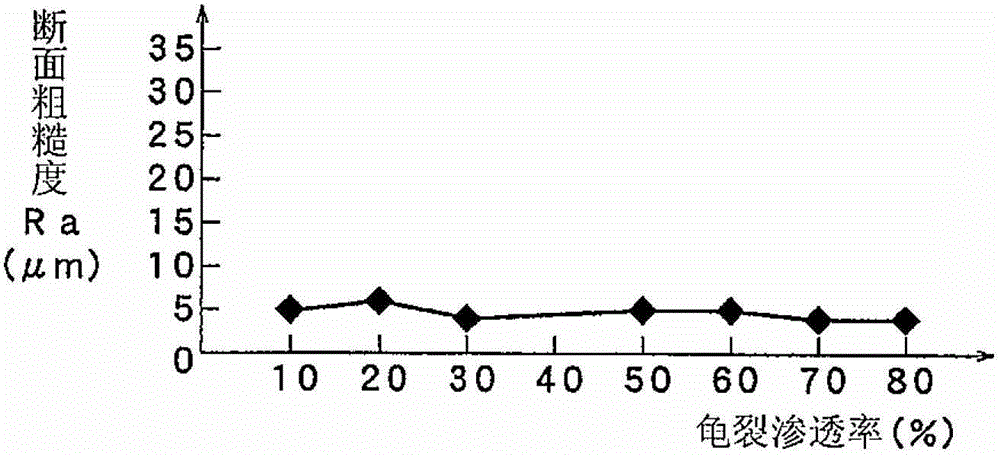

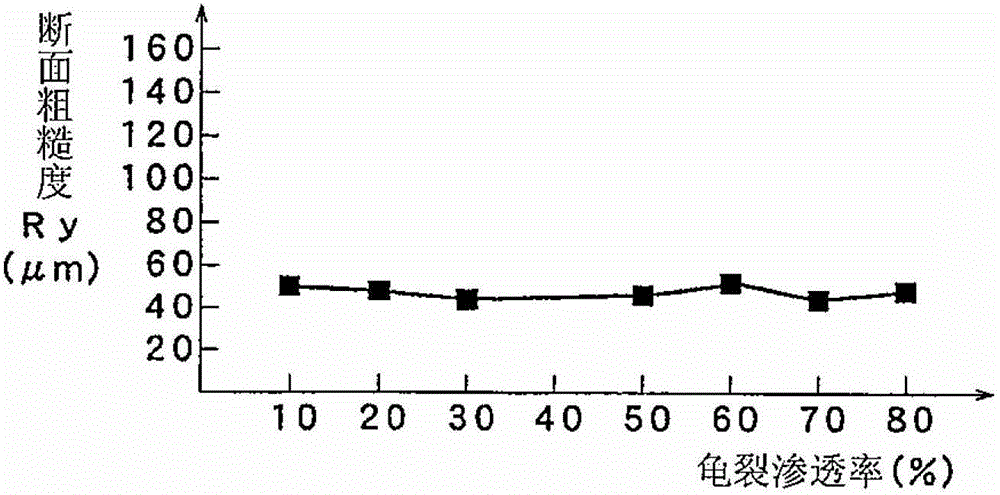

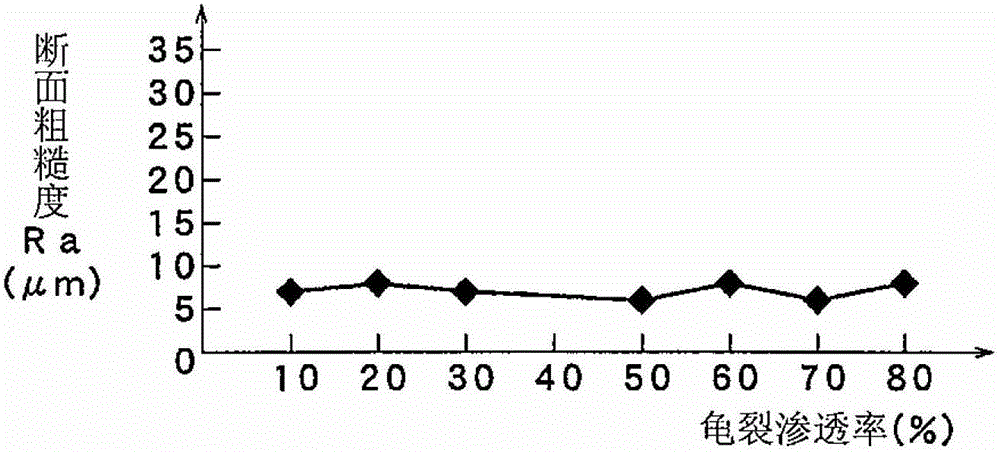

[0034] The target substrate of the present invention is an alumina substrate. Aluminum oxide (Al 2 o 3 ) content is, for example, 90% by weight or more, and the other part is mixed with additives such as binder (sintering aid), and is widely used as a substrate for semiconductor chips and the like. In the case of using an alumina substrate as a substrate of a chip component, for example, it is cut into a small chip shape of 2 mm square or less (1 mm square, etc.). When used as a substrate on which a plurality of parts are mounted, for example, it must be cut into a large size such as 100 mm square. If the alumina substrate is scribed and divided to be broken, if the angle of the knife tip is increased during scribing, the breaking strength can be reduced, thereby improving the quality of the end surface. Therefore, the inventors used a scoring wheel with a tip angle of 140° for alumina substrates, appropriately changed the crack permeability, divided the cracks after scorin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com