Method for calculating sheet belt surface defect density

A defect density and strip technology, applied in the field of counting strip surface defect density, can solve the problem of inability to count strip surface defect density and defect location, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

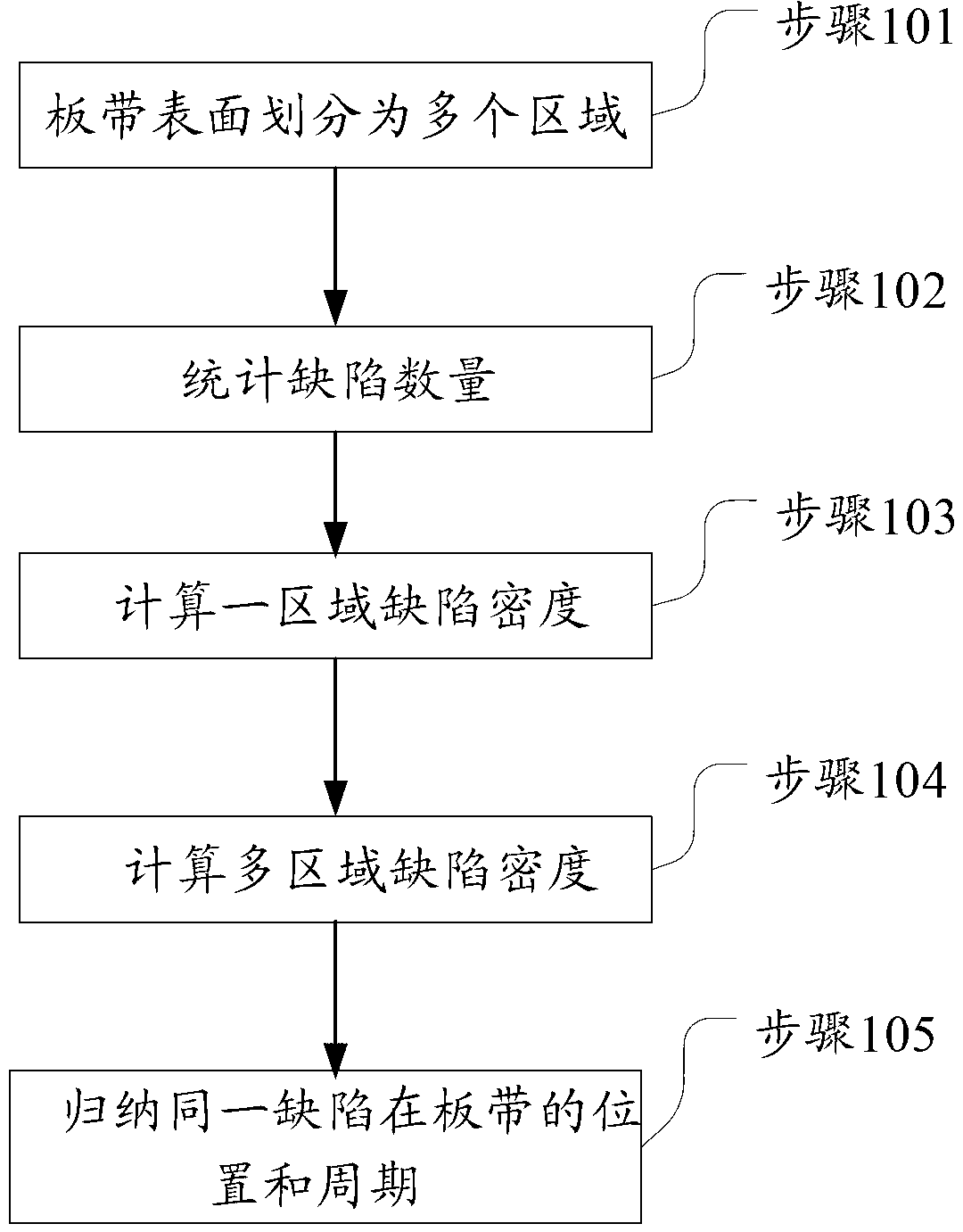

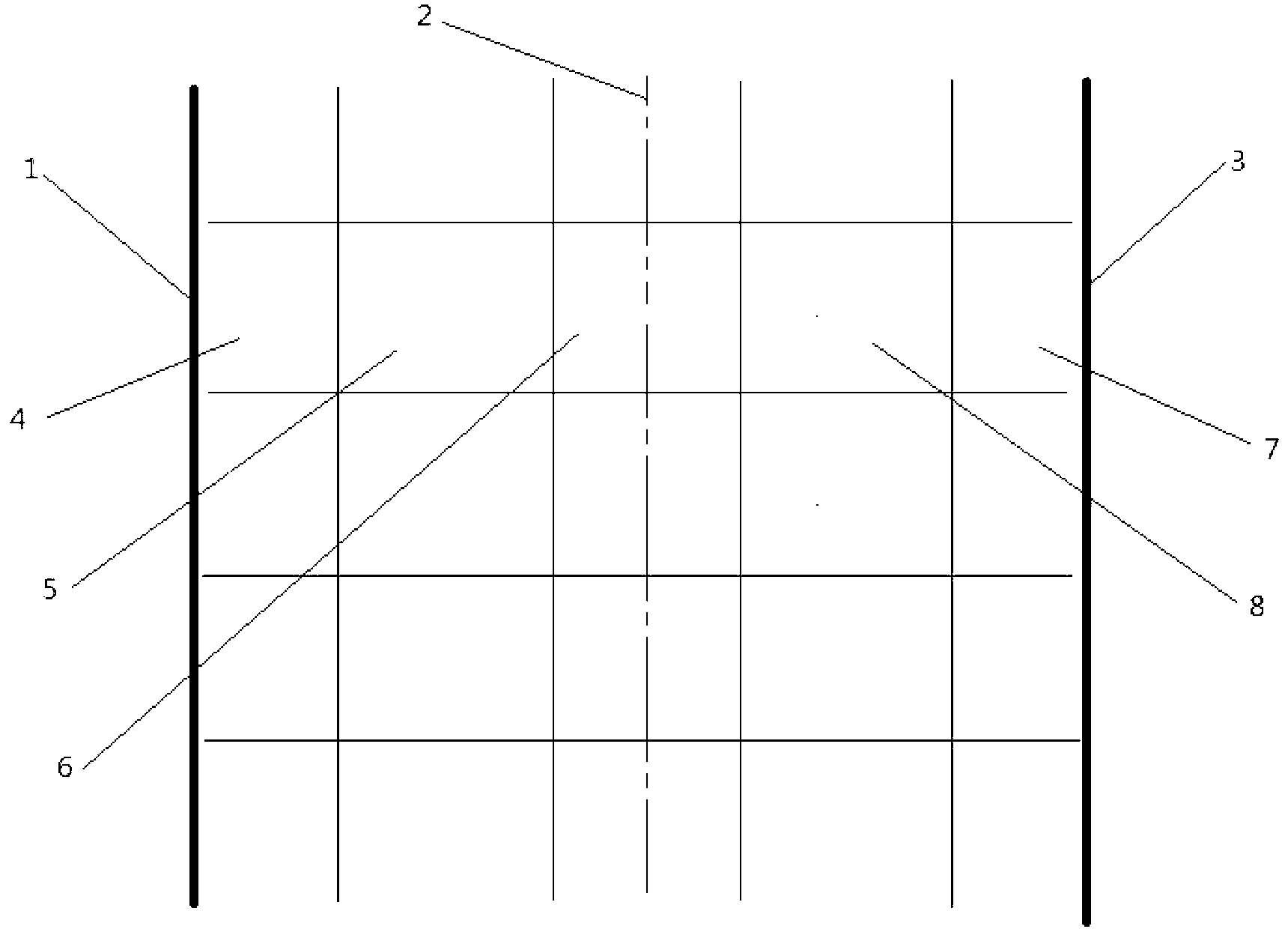

[0019] see figure 1 and figure 2 , a method for counting the surface defect density of a strip provided in an embodiment of the present invention specifically includes the following steps:

[0020] Step 101: dividing the surface of the strip into multiple regions;

[0021] Divide the surface of the strip into the left edge area 4, the left middle area 5, the center position area 6, the right middle area 8, and the right edge area 7; the division method of these 5 areas is: the left edge area 4 The distance between the longitudinal dividing line and the left edge line 1 is 200mm, and the distance between the horizontal dividing line is 400mm; the distance between the longitudinal dividing line of the center position area 6 and the center line 2 is 200mm, and the distance between the transverse dividing line is 400mm; The distance between the longitudinal dividing line and the right edge line 3 is 200mm, and the distance between the transverse dividing line is 400mm.

[0022...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com