Rod type lens array detecting apparatus and method

A rod lens and detection device technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of time-consuming, difficult detection, and troublesome comparison and processing of rod lens arrays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Next, an embodiment of the method for manufacturing a rod lens array of the present invention will be described with reference to the drawings.

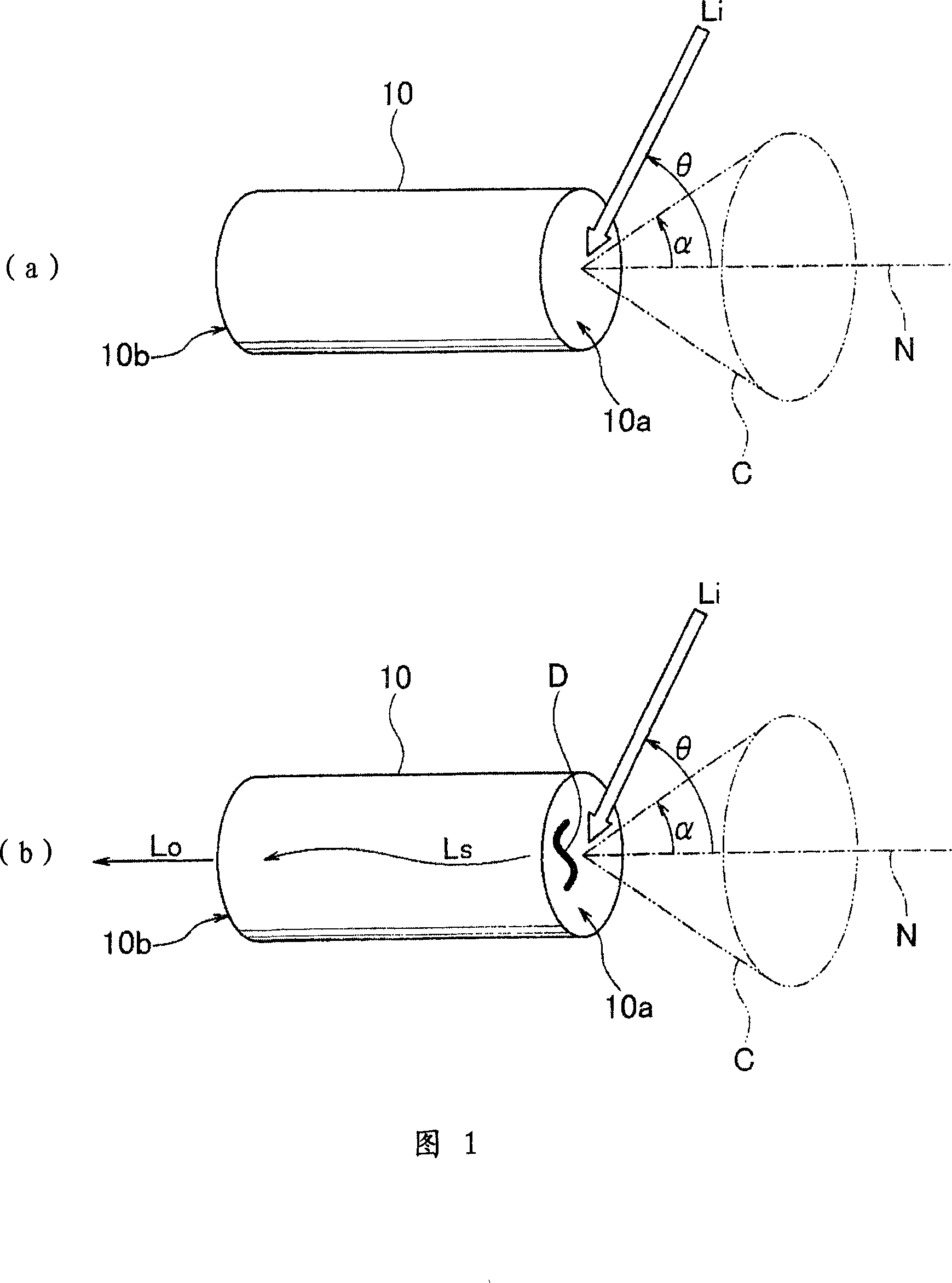

[0064] First, referring to the accompanying drawing 1, the principle of the detection method of the rod lens array of the present invention will be described.

[0065] FIG. 1( a ) and FIG. 1( b ) each typically show a refractive index distribution type rod lens 10 constituting a rod lens array. On the first end face 10a of each rod lens 10, the receiving pyramid C of the rod lens 10 is shown, and the half angle α of the maximum cone angle with respect to the normal N of the end face 10a is also shown.

[0066] The refractive index of the distributed refractive index rod lens 10 has a refractive index distribution that gradually decreases from the central axis toward the outer circular surface.

[0067] The above-mentioned refractive index distribution is on a section perpendicular to the central axis, and when the radius is R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com