Semi-automatic workpiece thickness rapid detection jig

A semi-automatic, workpiece-based technology, applied in the field of fixtures, can solve the problems of inspector fatigue, cumbersome operation, and inconvenient inspection work, and achieve the effects of high degree of automation, improved detection efficiency, and simple and fast detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

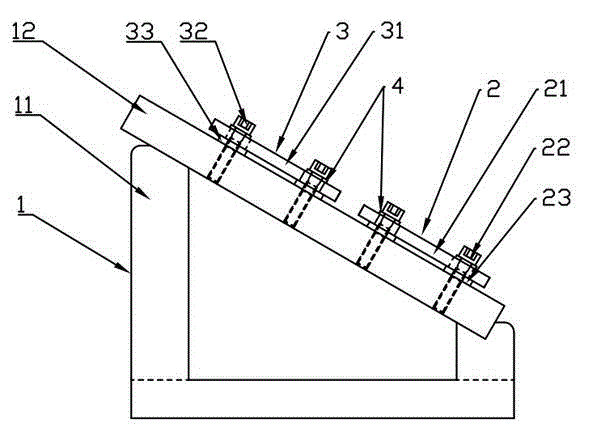

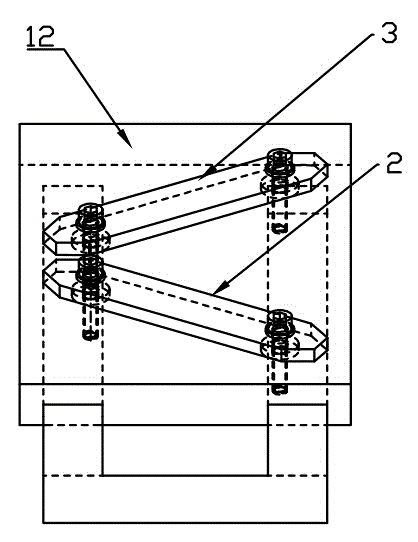

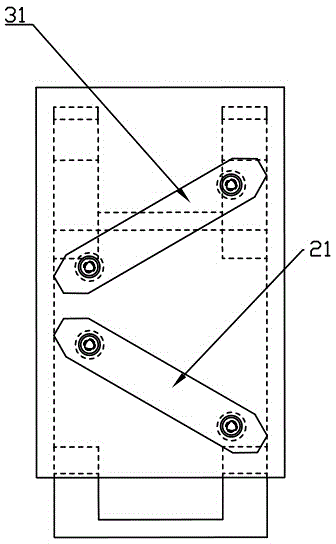

[0015] like Figures 1 to 3 As shown, a jig for detecting the thickness of a workpiece. The detected workpiece includes at least a gasket and a gasket. The detection device includes a fixture seat 1 and a stop unit 2 sequentially arranged on the top surface of the fixture seat 1 along the anti-gravity direction. The passing unit 3, that is, the passing unit is on the top and the stop unit is on the bottom. The top surface of the fixture base 1 is at an angle of 30° to 80° with the horizontal plane, and in this preferred embodiment, the fixture base 1 is composed of a base 11 and a bearing platform 12, the bearing platform 12 is arranged on the base 11, and the top surface of the bearing platform 12 It forms an included angle of 45° with the horizontal plane, and the top surface of the carrying platform 12 is provided with a plurality of screw holes.

[0016] The stop unit 2 is composed of a stop limit plate 21 and two stop screws 22, the two stop screws 22 are respectively ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com