Base device for large washing machine

A washing machine, a large-scale technology, applied in the direction of washing equipment, other washing machines, applications, etc., can solve the problems of increasing the cost of use and investment, and achieve the effects of improving the service life, optimizing the working environment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

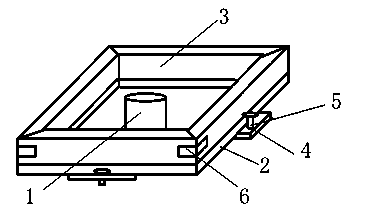

[0013] Such as figure 1 The shown base device for a large washing machine includes a water outlet guide column 1, which is connected to a floor drain or a sewer pipe. Rectangular base cushion 2. Specifically, in order to facilitate the complete integration of the rectangular base cushion 2 with the ground without skewing, a positioning component is arranged on the periphery of the rectangular base cushion 2 . At the same time, in order to increase the distance from the ground after the installation of the subsequent large-scale washing machine, in conjunction with the use of the water outlet guide column 1, the bearing enclosure 3 is distributed on the rectangular base cushion 2.

[0014] As far as a preferred embodiment of the present invention is concerned, in order to facilitate better positioning, the positioning assembly used in the present invention includes an extension fin 4 , and perforations are arranged on the extension fin 4 . At the same time, a screw 5 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com