Intelligent comprehensive evaluation method for cold-rolled strip shape

A comprehensive evaluation and strip shape technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of strip grade objection, loss of users and manufacturers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

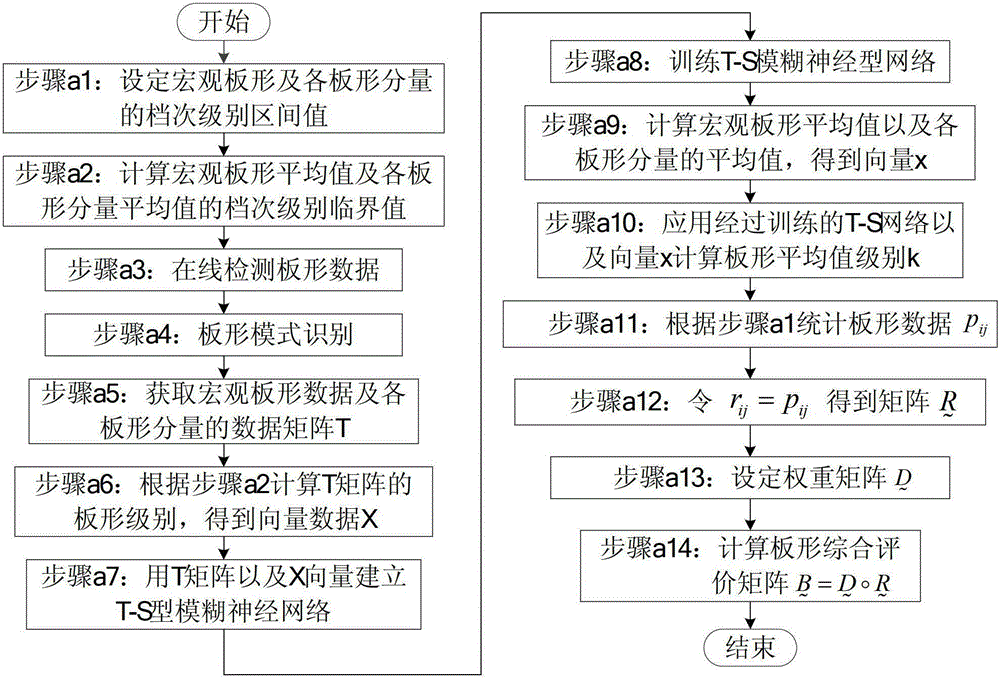

[0043] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

[0044] figure 1 It is the calculation flow chart of the intelligent comprehensive evaluation method of cold-rolled strip shape of the present invention. Now, taking the online detection data of one of the coils of a 1050 rolling mill as an example, an online flatness statistical model of cold-rolled strip steel is established. Collect the plate shape data of the 5th pass, the entrance thickness is 0.59mm, the exit thickness is 0.42mm, and the width is 910mm.

[0045] First, according to the actual production on site, set the interval value of the grade level of the macro flatness, and set the interval value of the grade level of each flatness component:

[0046]

Excellent

Good

Qualified

Unqualified

Macro plate shape / (I)

(I hmin,4]

(4,8]

(8,12]

(12,I hmax]

1st plate shape / (I)

(I 1min,1]

(1,2]

(2,3]

(3,I 1max]

Secondary plate shape / (I)

(I ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com